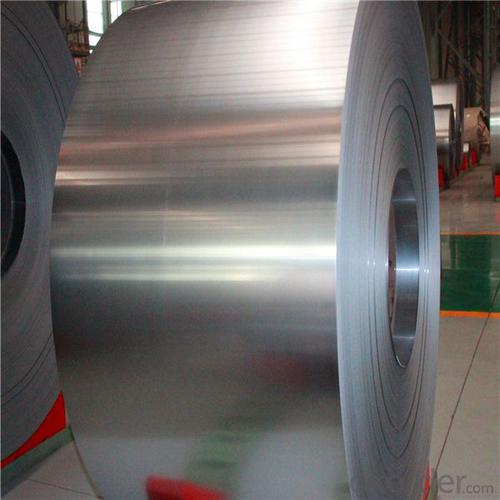

Prime Cold Rolled Steel Coils with Low Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Oiled,Bright

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B

Certification:

ISO,SGS,BV,CE

Thickness:

0.18mm-1.8mm

Width:

1000mm-1600mm

Length:

requirement

Outer Diameter:

according to weight

Net Weight:

10MT

Packaging:

Standard Export Packing

| Main Quality Standard | JIS3141, EN10130, DIN1623, ASTM A1008/1008M GB5213 |

| Annealing Type | 20 hydrogen annealing furnaces from Austria EBNER |

| Specification | 0.25mm upto 1.2mm ×900mm upto 1265mm |

| Weight | max 10,000kg |

| Yield Strength | 100 Mpa upto 280 Mpa |

| Products inside Diameter | φ508mm or φ610mm |

| Outer Diameter | max φ2,050mm |

| Packing | export standard packaging; horizontal packaging |

| Capacity | 300,000 tons/year |

Export standard seaworthy packaging

· Axial and circumferential steel straps with seal (4 steel straps each)

· VCI Anti-rust kraft paper

· Water-proofing plastic

· Pearl wool (coil surface)

· Steel cover (coil surface/bore)

· Plastic cover (coil sides)

· Inside and outside corner protectors

The reasons why customers choose us

1.High quality raw material

Our raw material is bought from some famous state-owned steel mills,such as WISCO,Baosteel,Ansteel,Tangsteel,etc.

2.High-precision thickness

The thickness tolerance can be reached +/-0.01mm.

The zinc layer mass range is from 30g/m2 to 275g/m2.

3.Customer-oriented concept

We try our best to find the solutions for customers and finnally meet their needs.

4.Advaned equipment and strict quality inspection

PRODUCT PICTURE

- Q: What are the factors affecting the price of steel coils?

- The factors affecting the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices and transportation costs. Other factors include market demand and supply dynamics, global economic conditions, currency exchange rates, government regulations, and tariffs. Additionally, technological advancements, production capacity, and competition within the steel industry can also influence the price of steel coils.

- Q: How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they provide a durable and versatile material for creating structural components such as panels, cladding, and roofing. The coils are processed and shaped into the desired form, allowing for easy customization and installation. The strength and resistance of steel make it an ideal choice for facades, ensuring long-lasting and aesthetically pleasing buildings.

- Q: What are the different methods of perforating steel coils?

- There are several methods of perforating steel coils, including rotary punch, laser cutting, and stamping. Each method offers its own advantages and is chosen based on factors such as the desired hole size, material thickness, and production volume. Rotary punch involves using a rotating tool to create holes in the steel coil, while laser cutting uses a high-powered laser beam. Stamping, on the other hand, involves using a die and press to create holes by applying pressure to the steel coil.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hello okorder / I'm not familiar with the brand...it's certainly not commonly played....but it has the features you need for a starter guitar.

- Q: How are steel coils inspected for thickness variations?

- Steel coils are inspected for thickness variations using non-destructive testing methods, such as ultrasonic or electromagnetic techniques. These methods involve the use of specialized equipment that can measure the thickness of the steel coil at various points, ensuring that it meets the required specifications.

- Q: What are the different types of surface finishes for steel coils?

- There are several different types of surface finishes for steel coils, each offering its own unique properties and advantages. Some of the most common surface finishes for steel coils include: 1. Hot Rolled: This is the most basic surface finish for steel coils and is achieved by heating the steel and then rolling it to its final shape. It typically has a rough and scale-like appearance, with varying levels of surface imperfections. 2. Cold Rolled: This surface finish is achieved by further processing hot rolled steel coils through a series of cold rolling operations. Cold rolled steel has a smoother and more uniform surface compared to hot rolled steel, with improved dimensional accuracy and better surface quality. 3. Galvanized: Galvanizing is a process in which a protective layer of zinc is applied to the surface of the steel coil. This surface finish provides excellent corrosion resistance, making it ideal for outdoor applications and environments where the steel is exposed to moisture and other corrosive elements. 4. Stainless Steel: Stainless steel coils have a unique surface finish due to the presence of chromium, which forms a thin, invisible layer of oxide on the surface. This surface finish provides excellent corrosion resistance and a visually appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this surface finish involves the application of a thin layer of zinc to the steel coil through an electroplating process. It provides good corrosion resistance and is commonly used in applications where aesthetics are important. 6. Pre-painted: Pre-painted steel coils have a surface finish that is coated with a layer of paint or other protective coatings. This finish offers both corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes to be applied. 7. Aluminized: Aluminized steel coils have a surface finish that is coated with a layer of aluminum-silicon alloy. This finish provides excellent heat resistance and is commonly used in applications where high temperatures are encountered, such as exhaust systems or ovens. Overall, the choice of surface finish for steel coils depends on the specific requirements of the application, including factors such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: How are steel coils used in the production of metal signs?

- Steel coils are used in the production of metal signs as they are processed and shaped into flat sheets that serve as the base material for the signs. These coils are unrolled and flattened, then cut and formed into the desired shape before being painted or coated for aesthetics and protection.

- Q: How are steel coils used in the manufacturing of tubes?

- Steel coils are commonly used in the manufacturing of tubes as they provide a continuous and uniform supply of high-quality steel material. These coils are processed through various stages, including slitting, forming, and welding, to create tubes of different sizes and shapes. The steel coils are unrolled, cut into strips, and then formed into a cylindrical shape. The edges of the strips are welded together to create a seamless tube. This process ensures the production of strong and reliable tubes that are widely used in industries such as construction, automotive, and manufacturing.

- Q: What are the different methods of coil slitting for steel coils?

- There are several methods of coil slitting for steel coils, including rotary shear slitting, loop slitting, and drag slitting. Rotary shear slitting involves using rotating knives to cut the coil into narrower strips. Loop slitting involves creating a loop in the coil and feeding it through a set of knives to slit it. Drag slitting involves pulling the coil through stationary knives to slit it. Each method has its own advantages and is chosen based on the specific requirements of the application.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Prime Cold Rolled Steel Coils with Low Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords