Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

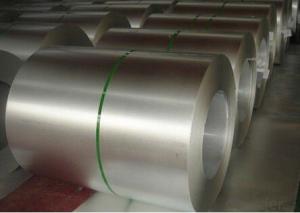

Pictures for stainless steel coil :

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: i have searched high and low, but can't find information anywhere!bainitic and pearlitic steels are too in depth, just would like to know if it is hsla steel, or mild steel, or stainless steel etc...thank you in advance :)

- I don't know what the technical name is, but steel used in rail is higher in carbon content. There is a trade-off as the higher carbon content tends to make them more brittle, and those rails with the highest carbon content are used exclusively for tight curvature in heavy grade. It's amazing to watch the welders with this stuff. Torches take too long, so diamond saws are utilized for cutting. The stuff is more problematic in severe cold, too. Railroading in the mountains as I've always done, nighttime and its severe chill causes pull - aparts, due to the contraction of CWR (Continuous Welded Rail) as a result of the cold, at least two or three times a week. In an extended deep freeze, the problems are nightly. What is interesting to note is that the pull aparts tend to happen with equal frequency regardless of whether a part of tangent track or curve. Still, I'd rather have it under me. I know it caused some major problems on the SP in the '80s, but it was cheaper, imported steel that was the significant part of the problem, not so much the high carbon content. Once again, you can't beat US steel.

- Q: How are steel coils inspected for surface finish?

- Steel coils are inspected for surface finish through a visual examination by trained inspectors. They carefully inspect the coils for any defects, such as scratches, pits, or uneven surfaces. Additionally, specialized equipment like optical scanners or digital cameras may be used to capture high-resolution images for a more detailed analysis. The goal is to ensure that the surface finish of the steel coils meets the required standards and is free from any imperfections that could affect its quality or performance.

- Q: How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they are rolled and formed into the required shapes and sizes to create the structural components of the towers. The coils are processed and cut into specific lengths, which are then welded or bolted together to construct the tower sections. The robustness and strength of steel make it an ideal material for transmitting large amounts of electricity over long distances, ensuring the stability and reliability of power transmission towers.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- a lot of people that do a lot of manual labor with their hands prefer stainless steel because it can withstand potential damage on the job.

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- The biggest problem is the FULL choke on the end of the barrel. Steel pellets are harder than lead, so they find it hard to squeeze through the tight full choke. If you do it, you WILL either bulge or crack the muzzle end of the barrel. That is a fact. Newer model 870 shotguns with RemChokes can fire steel, but you have to use a lead MODIFIED choke to send a full pattern down range. Again, for the same reason I mentioned earlier - that the steel does not deform and squeeze itself through the tighter chokes as well. See photo link below at what your barrel will look like after a box of steel shot.

- Q: Can we construct a barn using steel and will it be a durable one?

- Steel barns in the USA is the going fad; they are both strong and economical; and some companies offer DIY kits

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- Folding Sword

- Q: How are steel coils used in the production of automotive chassis?

- Steel coils are used in the production of automotive chassis as they are cut and shaped into various components, such as frame rails and crossmembers, which form the structural foundation of the vehicle. The high strength and durability of steel make it an ideal material for chassis construction, providing stability and safety to the overall vehicle structure.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- I'm afraid you have opened a can o'worms. Aluminum as a material is roughly 1/2 the weight of steel. Aluminum as a material is also roughly 1/3 the strength of steel. his means you need 3 times more aluminum to make a frame as strong as steel which makes the aluminum frame 25% heavier. That being said, well designed and more expensive aluminum frames can easily weigh less than low zoot steel. Buying a cheap bike with an aluminum frame will ALWAYS weigh more than a middle of the road bike with a steel frame. ...and THAT being said, high end steel can easily weigh less than a high quality aluminum frame... note we are talking frames in the $2000 range- just for the frame. So, based on your explanation and attendant budget of the bikes you are considering, buy the steel bike. You won't be losing or gaining anything... except saving money.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knife

Send your message to us

Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords