Prestressed Concrete Hollow Core Slab Mold

- Loading Port:

- Qingdao

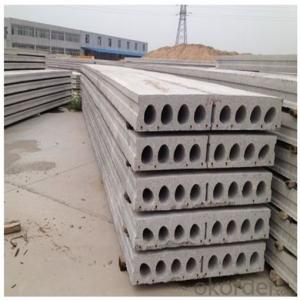

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prestressed Concrete Hollow Core Slab Mold

1. Structure of Prestressed Concrete Hollow Core Slab Mold:

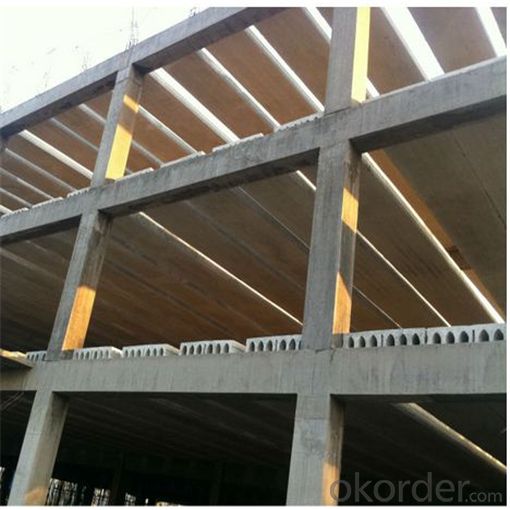

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of Prestressed Concrete Hollow Core Slab Mold:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Prestressed Concrete Hollow Core Slab Mold Images:

4. Prestressed Concrete Hollow Core Slab Mold Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: would you be able to give reasons

- the general consensus is that the type of financing should match the lifespan of whatever you're buying. so for heavy machinery, these are typically long-term assets. as such, you want to use long-term debt (such as a long-term bank loan). ideally, the best financing is cash (you buy it outright). other alternatives would be to give the seller a corporate bond which promises them payments, etc. loan agreements are another option.

- Q: i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- are you referring to triceps? If so, do chair dips. side leaning dumbell raise, laying side tri rise. These are crucial for bigger arms. Triceps. Just look up shoulders and arms from p90x. it'll help you.

- Q: Gain on sales of machinery would be recorded as what? Debit or Credit?

- Gain on sale of machinery is going to be a revenue account (hence credit to increase). The dollar amount of the gain would equal the difference between the book value of the machinery and the amount received for it. Debit 'Cash' for amount received, debit 'Accumulated Depreciation - Machinery' for the total amount that it has been depreciated, credit 'Machinery' for the original cost of it, and credit 'Gain on Sale of Machinery' for the amount that makes the journal entry be in balance.

- Q: This is really our project to investigate, what's the significance of this and how it is done attractively? Yah, were going to defend it by the questions from the judges. What could be the possible questions? Does anyone have an idea? If you give me a detail answers, I will not refuse to give you 10 points.

- the significance would be it makes the farmer's easy for their work about that, you better study it

- Q: what is machinery?and its uses.?

- What Is Machinery

- Q: electric digram for desel generator wih 105 kva

- Call or write to the manufacturer.

- Q: What are the main considerations when choosing mechanical parts?

- Heat treatment conditions, there is no heat treatment conditions and no heat treatment conditions of the election of different materials; the weight requirements, often mentioned in the hands of the parts require light, to meet the mechanical strength conditions can choose a small proportion of material, life requirements

- Q: Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- No, because you have to have strong steady arms, muscles in hand and arm to operate such things and if they become too powerful to operate you could have a bad accident, so I would always prefer to stay away from heavy machinery.

- Q: I have a stepson who has a keen interest in combine harvesters and I had the idea to take him to see them being built at a farm machinery manufacturer somewhere, but have no idea who to enquire for about this and whether they would allow a factory tour to see these machines being put together. Does anyone have information that could be of help to me to arrange this for him as a surprise day out? Thanks.

- John okorder /

- Q: What are the effects of heat treatment on the mechanical properties of metallic materials

- Tempering: Reduce and eliminate the internal stress of steel after quenching. Stable organization and size.

Send your message to us

Prestressed Concrete Hollow Core Slab Mold

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords