Prepainted Rolled Steel Coil for Roofing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description Info.

Surface Treatment:Coated

Technique:Cold Rolled

Standard:JIS

Color:All Ral Color Are Available

Zinc Coating:30-120G/M2

Width:914-1250mm

Thickness:0.18-0.6mm

Export Markets:Global

Additional Info.

Trademark:VST

Packing:Standard Export Package

Origin:China

Production Capacity:10000t/Month

Main Feature:

1, Pre-painted Steel Coil Can be used in building material field, galvanized wire steel tape and mainly other fields.

2, All color can be customized

3, Good quality with competitive price

Secifications

Performance testing of color coated steel coil | ||

Item | Method | Consequence |

Tensile Test | Tic-Tac-9mm 5mm cross cupping | No damage |

Bending Test | T≤ 3 | No damage |

Boiling Test | 100° Cboiling 1 hour | No damage |

Water Resistance | 1000hours immersion in 40° C(edge) | No damage |

Moisture Resistance | 50° C90%100hours(edge) | No damage |

Fire Resistance | Samples were placed in incubators, remove greenhouse cooling, and then test the adhesion | Long-term Environment in 100° C |

Fire Extinction | Liquefied petroleum gas or natural gas burner | Immediately turn off |

Drug Resistance | 10%hydrochloric acid, saturated calcium, 10%H2SO4, 10%NAOH, gasoline, ethanol | No color and trace change |

Salt spray test | 5%Nacl, 35± 2° C, 500hours | No damage |

Coating performance test standard | ||

Test item | Positive standard | Back standard |

Dry film thickness(um) | 14-16 | 7-9 |

Glass(60degree) | High 70± 5, medium40± 5, low30± 5 | 30± 5degree |

T bending | 3 | 3 |

Impact strength | 6.3 | 5.8 |

Pencil hardness(H) | H | H |

MEK(Per) | > 100 | > 100 |

Cross cut | 0 class | 0 class |

Acid resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

Alkali resistance | 50%H2SO4 immersion in300hrs, no color, wrinkling, fading, change | |

Aging-resistance | 1 st class loss of color and glass | |

Salt spray | 500 | |

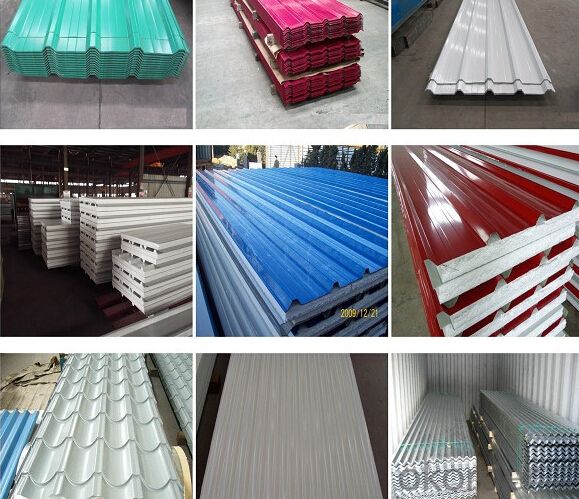

Images

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers to provide strength, durability, and structural integrity. These coils are processed and shaped into the necessary components, such as walls, floors, and roofs, which are then assembled to create a sturdy container. The steel coils also allow for easy transportation and stacking of the containers, ensuring safe and efficient shipping of goods worldwide.

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- rust is oxidation . remove contact with O2 , it wont rust . you can place it in a oxygen free atmosphere , you could plate it with zinc or chrome , you can use a lead based paint .

- Q: How are steel coils packaged for transportation?

- Steel coils are typically packaged for transportation using a variety of methods to ensure their safe and secure delivery. The packaging process involves several steps to protect the coils from damage during transit and to facilitate their handling and loading onto trucks, ships, or trains. Firstly, steel coils are tightly wound and bound using steel straps or bands to keep them compact and prevent unwinding. These straps are usually made of high-strength steel and are securely fastened around the circumference of the coil at regular intervals. This helps to maintain the coil's shape and prevent any movement during transportation. Next, the coils are often placed on wooden or steel pallets to provide a stable base and facilitate handling with forklifts or cranes. The pallets are usually sized to fit the dimensions of the coils and are designed to withstand the weight and stress of the loaded coils. To provide additional protection, steel coils are often covered with a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also helps to prevent scratching or damage to the outer surface of the coils. Furthermore, to secure the coils and prevent shifting during transit, they are often placed within a steel or wooden crate. These crates provide an extra layer of protection and stability, particularly for larger coils or when multiple coils are being transported together. Finally, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During loading, proper care is taken to ensure that the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents during transit. In summary, steel coils are packaged for transportation by tightly binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging process helps to safeguard the coils and ensure their safe and efficient transportation to their destination.

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are inspected for damage during transportation through various methods such as visual inspections, magnetic particle testing, ultrasonic testing, and dimensional checks.

- Q: I know of the cheaper steel shot for waterfoul hunting, but there is more expensive shot available. Is it worth the money, how much more distance are we talking, and what do you like the best?(brand name)

- In my experience with steel shot, I found that the higher quality stuff usually just patterns more consistently. Although I prefer Federal, any of the other major manufactuers are also great.

- Q: What are the different grades of steel used for coils?

- The different grades of steel used for coils vary depending on the specific application and requirements. Some common grades include low carbon steel (C1008/1010), medium carbon steel (C1045), high carbon steel (C1070/1095), stainless steel (304/316), and advanced high-strength steels (AHSS) like dual-phase (DP), transformation-induced plasticity (TRIP), and martensitic (MS). Each grade offers different properties such as strength, corrosion resistance, formability, and weldability, allowing manufacturers to choose the most suitable grade for their coil production.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets by being processed and cut into the desired shape and size. The coils serve as the primary raw material, providing the necessary strength and durability for the brackets.

- Q: What are the different types of steel coil finishes?

- There are several types of steel coil finishes, including hot rolled, cold rolled, galvanized, and stainless steel.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as the primary material for producing pipes and tubing. These coils are processed and formed into various shapes and sizes to create the necessary components, such as the main exhaust pipe and smaller sections for mufflers and catalytic converters. The steel's strength and durability make it an ideal choice for withstanding the high temperatures and corrosive nature of exhaust gases, ensuring the longevity and functionality of the system.

- Q: What are the common problems encountered with steel coils during production?

- There are several common problems encountered with steel coils during production. One of the most common issues is coil slippage, where the coils shift or slide out of place during handling or transportation. This can result in damage to the coils or pose a safety risk to workers. Another common problem is coil rusting or corrosion. Steel coils are susceptible to rusting if they come into contact with moisture or are not properly protected. Rust can compromise the structural integrity of the coils and lead to product defects or failure. Coil breakage is also a common problem. This occurs when the coils are subjected to excessive stress or tension, causing them to crack or break. Coil breakage can result from improper handling or storage, as well as production issues such as improper rolling or cooling processes. Coil surface defects are another common issue. These defects can include scratches, dents, or uneven surfaces on the coils. Surface defects can compromise the appearance and quality of the final product, making it unsuitable for certain applications. Lastly, coil contamination is a problem that can occur during production. Contaminants such as dirt, oil, or foreign particles can adhere to the surface of the coils, leading to quality issues or difficulties in further processing. Contamination can result from improper handling, inadequate cleaning processes, or poor environmental control. To mitigate these common problems, proper handling and storage practices are essential. This includes using appropriate lifting and transporting equipment, ensuring the coils are stored in a dry and clean environment, and implementing effective rust prevention measures. Regular inspections and quality control checks can also help identify and address any issues early on, preventing further damage and ensuring the production of high-quality steel coils.

Send your message to us

Prepainted Rolled Steel Coil for Roofing Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords