Prepainted Galvanized steel Coil of Good Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

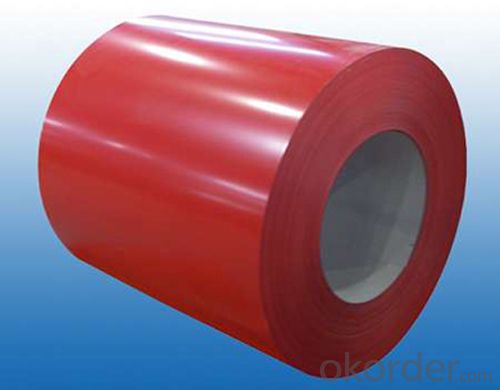

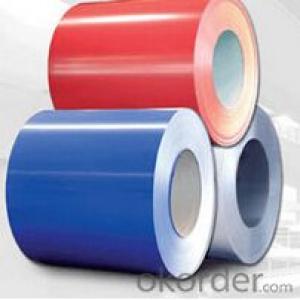

1.Structure of Prepainted Galvanized steel Coil

With Gi as base metal, after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding, corrosion resistance

2.Main Features of Pre-painted Galvanized steel Coil

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized steel Coil Images

4. Pre-painted Galvanized steel Coil Specification

Standard: ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

4.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

5.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

6. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: If rail ties were melted, would they be like any other type of steel?

- As so much about the railroad is variable, so is the steel used for the rail. For one thing, all rail is not the same size. It is classified by weight per yard. For example, most tangent (straight) track is 139 lbs rail, meaning three feet of it weighs this much. Secondary track, such as found on branch lines and in yards or used on sidings is not as heavy. Track used in curvature may be the same weight, but not always. The reason is there is much more stress imparted to the roadbed in curvature. Most steel on main tracks has a higher carbon content, but there is a point of diminishing returns, as this rail is more brittle as a result. Good luck trying to melt it. In the field, this rail is cut by a saw with diamond studded circular blades. The reason why is it takes a lot more time to try to cut it with an acetylene torch. In the US, certain areas, such as on some bridges, the cross-ties (sleepers) are indeed made of steel, in addition to concrete and wood. The potential for fire is too great for wood in these instances. In addition, if even a single wheel derails, concrete ties tend to explode when stressed this way. All of which makes steel cross-ties worth the extra cost.

- Q: Are steel coils used in construction?

- Yes, steel coils are commonly used in construction. They are often used in the manufacturing of structural components, such as beams, columns, and trusses, as well as in the construction of metal buildings and infrastructure projects. Steel coils provide strength, durability, and versatility to various construction applications.

- Q: What is the average lifespan of a steel coil?

- Several factors can influence the average lifespan of a steel coil. These factors encompass the quality and type of steel utilized, the conditions in which the coil is stored or used, and the maintenance and care it receives. Typically, a steel coil that is well-maintained can endure for approximately 10 to 30 years. Nevertheless, this is merely an approximation, and the actual lifespan can be either shorter or longer depending on the aforementioned factors. For example, if the coil is exposed to severe environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be diminished. Regular upkeep and proper storage can significantly prolong the longevity of a steel coil. This entails ensuring that the coil is stored in a dry and safeguarded environment, frequently inspecting and addressing any indications of corrosion or damage, and conducting routine cleaning and lubrication as necessary. Ultimately, the average lifespan of a steel coil is contingent upon various factors, and it is advisable to consult the manufacturer or industry experts for a more precise estimation based on specific circumstances and conditions.

- Q: What are the dimensions of steel coils used in the construction equipment industry?

- The dimensions of steel coils utilized in the construction equipment industry may differ depending on the particular application and requirements at hand. Nevertheless, there exist standard dimensions that are commonly employed. Typically, steel coils employed in the construction equipment industry possess a width ranging from 600mm to 2000mm. The thickness of these coils can vary from 0.5mm to 25mm or potentially higher, contingent upon the intended purpose and structural prerequisites. The weight of steel coils utilized in the construction equipment industry can differ significantly, spanning from a few hundred kilograms to numerous tonnes. The weight is typically determined by the dimensions and thickness of the coil, as well as the specific grade and type of steel employed. It is crucial to note that these dimensions are not fixed and can be tailored to cater to the specific needs of the construction equipment industry. Manufacturers and suppliers have the capability to provide steel coils in various dimensions to fulfill the precise requirements of construction equipment manufacturers and contractors.

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery using various cutting methods such as shearing, slitting, or laser cutting, depending on the desired specifications and requirements.

- Q: What are the various surface finishes available for steel coils?

- The various surface finishes available for steel coils include hot-rolled, cold-rolled, galvanized, coated, and polished finishes.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being fed into wire drawing machines where they are elongated and reduced in diameter to the desired thickness. The steel coils provide a continuous supply of raw material, ensuring a seamless production process for manufacturing wires of various sizes and applications.

- Q: How are steel coils used in the manufacturing of safety systems?

- Steel coils are commonly used in the manufacturing of safety systems such as airbags and seat belts. The steel coils are formed into springs which provide the necessary tension and force to ensure the proper functioning of these safety devices. The coils are carefully designed and integrated into the system to enhance its performance and reliability, ultimately helping to protect occupants in the event of a collision.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- This Site Might Help You. RE: Do stainless steel mood rings rust? I bought a stainless steel mood ring two days ago, but would it rust? Thanks in advance!

- Q: What are the common methods of inspecting steel coils for quality control?

- Steel coils are inspected for quality control purposes using various methods. These methods involve visual inspection, dimensional measurement, and non-destructive testing. To inspect steel coils, visual inspection is a commonly used and straightforward method. This entails visually examining the surface of the coils for any visible defects such as scratches, dents, or discoloration. Visual inspection also includes checking the labeling, packaging, and identifying signs of corrosion or damage. Another crucial method to ensure quality is dimensional measurement. This involves measuring different dimensions of the coils, such as thickness, width, and length, to ensure they meet the required specifications. Tools like calipers, micrometers, or laser measurement devices can be utilized for dimensional measurement. Non-destructive testing (NDT) techniques are also widely employed in steel coil inspection. NDT methods enable the detection of internal and surface defects without causing damage to the material. Ultrasonic testing is a common NDT technique used for steel coil inspection. It works by sending high-frequency sound waves through the coil and analyzing the reflected waves to identify any defects. In addition, magnetic particle testing and dye penetrant testing are used to detect surface cracks or defects in the coils. Apart from these methods, other quality control practices may include chemical analysis to ensure the steel's composition meets the required standards, mechanical testing to assess the strength and hardness of the material, and corrosion testing to evaluate the coils' resistance to corrosion. In summary, a combination of visual inspection, dimensional measurement, and non-destructive testing techniques is typically employed to ensure the quality and integrity of steel coils during the quality control process.

Send your message to us

Prepainted Galvanized steel Coil of Good Qualities

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords