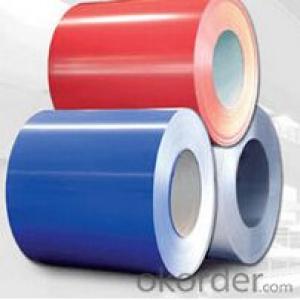

Prepainted Galvanized Rolled Steel Coil SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

Specification:

Thickness:0.15-0.8mm

Width:600-1250mm

Length:on request

Zinccoating: 30-275g/m2

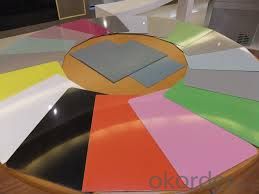

Color:RAL series

Paint:PE, PVDF, PU

Application:

1.Buildings and constructions:roofing, ceilings, gutters, venting lines, indoor decorations,windowframes, etc

2.Electrical appliances:computer shells, washing machines, refrigerators, dehumidifiers,videorecorders, water heaters, etc.

3. Agriculturalequipments: troughs, feeding tools, agricultural driers, irrigation channels,etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Packaging & Delivery

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images:

- Q: Can you recycle steel? And if you wanted to buy some recycled steel, where would you get it?

- Steel is the most recycled material. But in recycling steel you would need the usual equipment in a foundry. The finished (recycled) product cannot be discerned visually. You cannot differ it from those coming from virgin steel ingots. The finished product (or steel material) would have to depend on your requirement, whether it is for structural, architectural or otherwise. For your requirement (enough to build a cruise ship), it would be best to go to a smelter. You might get better prices and quality compared to that from a scrap yard.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to serve as a form of material storage and transportation for various industries. These coils are typically made by winding steel strips into a circular shape, providing a compact and efficient way to store large quantities of steel. Steel coils are used in numerous applications, such as manufacturing, construction, automotive, and appliance industries, where they can be easily transported, processed, and formed into the desired shape for different products.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- You can try Stainless Steel wipes. Weiman is a good brand

- Q: How do steel coils contribute to structural integrity in buildings?

- Steel coils play a crucial role in contributing to the structural integrity of buildings in several ways. Firstly, steel coils are widely used in the construction industry for manufacturing various building components such as beams, columns, and trusses. These components are responsible for providing support and stability to the overall structure. Due to their high tensile strength and durability, steel coils ensure that these components can withstand heavy loads and maintain their structural integrity over time. This is especially important in buildings with multiple floors or large open spaces, where the structural elements need to bear significant weight without deforming or collapsing. Secondly, steel coils are also used in the reinforcement of concrete structures. Reinforced concrete is a widely adopted construction method, and steel coils, in the form of reinforcement bars or mesh, are embedded within the concrete to counteract tensile forces. Concrete is excellent at withstanding compressive forces but weak in tension. By adding steel coils, the composite material gains the ability to resist both compression and tension, leading to enhanced structural integrity. This reinforcement technique is particularly vital in high-rise buildings or structures subject to seismic activity, where the risk of structural failure due to bending or cracking is higher. Another way steel coils contribute to structural integrity is through their corrosion resistance properties. Steel coils are often coated with protective layers, such as zinc through galvanization or paint, to prevent corrosion caused by moisture, chemicals, or environmental factors. Corrosion weakens the structural integrity of steel, leading to degradation and potential failure. By using corrosion-resistant steel coils, the lifespan of the building is extended, and the risk of structural damage is significantly reduced. Furthermore, steel coils offer versatility in design and construction. Their flexibility and malleability allow for the creation of complex and intricate building structures, enabling architects and engineers to push the boundaries of design while maintaining structural integrity. Steel coils can be shaped, bent, and welded into various forms, making them an ideal material for constructing innovative and aesthetically pleasing buildings. In conclusion, steel coils contribute significantly to the structural integrity of buildings by providing strength, stability, and durability to various components and reinforcement systems. Their high tensile strength, corrosion resistance, and versatility in design make them an indispensable material in modern construction, ensuring the safety and durability of buildings for years to come.

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled with extreme care during transportation to prevent damage. They are secured tightly using steel strapping or bands to prevent any movement or shifting during transit. Additionally, protective packaging materials, such as wooden or steel crates, are often used to provide extra cushioning and stability. Specialized equipment, such as forklifts or cranes, are used to lift and load the coils onto trucks or containers, ensuring safe and secure transportation.

- Q: Which type is better and give reasons why... I making a team of either Dark or Steel :D Thankyou

- Steel-type Pokemon are strong against Ice and Rock-type Pokemon, weak against Fire, Fighting, and Ground-type moves, resistant to Dark, Dragon, Ghost, Grass, Ice, Normal, Psychic, Rock, and Steel-type moves, and are immune to Poison-type moves. Notable Steel-type Pokemon include Skarmory, Scizor, and Metagross. Dark-type Pokemon are strong against Ghost and Psychic-type Pokemon, weak against Bug and Fighting-type moves, resistant to Ghost-type moves, and immune to Psychic-type moves. Notable Dark-type Pokemon include Houndoom, Murkrow, and Sneasel. Steel-type Pokemon have more resistances than Dark-types, but more weaknesses as well. In truth, no one type is better than any other, and making a team composed entirely of a single type may make some battles difficult. It's best to keep your options open, and go with a wide variety of types.

- Q: How are steel coils used in the production of pipes and tubes?

- Steel coils play a crucial role in the manufacturing of pipes and tubes. They serve as the primary material for shaping the cylindrical structure of these products. The process begins by unrolling the coils and feeding them into a pipe or tube mill, where a series of manufacturing procedures take place. Initially, the steel coils are unwound and straightened to eliminate any bends or twists. Subsequently, the edges of the coils are trimmed to ensure a smooth and even surface, a technique referred to as slitting. Following this, the coils are passed through a forming machine, which bends them into the desired shape. For pipes, the coils are shaped into a circular form, whereas tubes can be molded into different configurations like square, rectangular, or oval. Once the coils have been shaped, they are welded together along their length to create a continuous pipe or tube. This welding process can be accomplished using a variety of techniques, such as high-frequency induction welding, electric resistance welding, or submerged arc welding. After the welding process is complete, additional procedures may be carried out on the pipes or tubes to enhance their properties. These procedures may involve heat treatment, like annealing or quenching, to improve strength or hardness. Finally, the pipes or tubes are cut to the desired length and may undergo further finishing processes, such as straightening, polishing, or coating, depending on their intended application. In summary, steel coils serve as the foundational material in the production of pipes and tubes. They are unrolled, straightened, and molded into the desired shape before being welded together to create a continuous product. Additional processes can be applied to improve the properties and meet specific requirements of the pipes or tubes.

- Q: How are steel coils unloaded from a truck or ship?

- Steel coils are typically unloaded from a truck or ship using various equipment and techniques. The unloading process depends on the type and size of the coils, as well as the available resources and infrastructure at the unloading site. For unloading from a truck, a common method involves the use of a forklift or crane equipped with coil hooks. The coils are carefully lifted and positioned onto the ground or a designated storage area. Alternatively, some trucks may be equipped with specialized roll-off trailers that allow the coils to be rolled off the truck bed. When unloading from a ship, larger cranes are often used due to the size and weight of the coils. These cranes can be located either on the ship itself or on the dock. The coils are lifted from the ship's cargo hold using specialized lifting hooks or spreader bars and carefully lowered onto the dock or a waiting truck. In some cases, a coil transfer car or coil trailer may be utilized to move the coils from the ship's cargo hold to the unloading area. These devices are designed to transport and position the coils safely and efficiently. It is worth noting that safety measures are of utmost importance during the unloading process. Proper securing of the coils, equipment stability, and adherence to weight limits are crucial to prevent accidents or damage to the coils, the truck, or the ship. Overall, the unloading of steel coils from trucks or ships involves the use of specialized equipment such as cranes, forklifts, and coil hooks. These tools, along with proper planning and safety precautions, ensure the efficient and safe transfer of the coils to their designated storage or transportation areas.

Send your message to us

Prepainted Galvanized Rolled Steel Coil SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords