Prepaintd galvanized steel coils Any color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard sea worthy export packing with reinforce |

| Delivery Detail: | 15 days after receiving the advance payment |

Specifications

Thickness:0.12-2.0mm

width:650-1250mm

Zinc coating:40-200g/m2

Certificates:ISO9001:2000, SGS, SONCAP

Standard: ASTM,JIS,GB

Brief introduction:

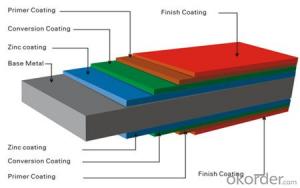

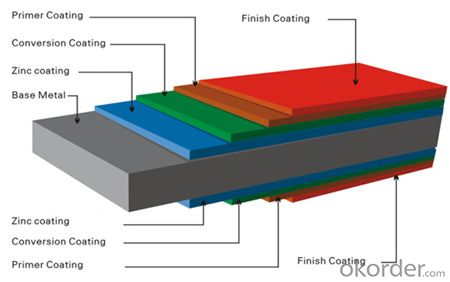

Galvanized steel coils are produced through a process of metal coating which involves passing cold rolled coils through a zinc pot. The process ensures the adherence of zinc to the surface of steel sheet. The zinc layer provides excellent corrosion resistance so that it can prolong the service life of the product..

Hot dipped galvanized products are widely used in roofing, household appliance, container manufacturing, base material for pre-painting, ducting(pipe) and other construction related appliance.

Color coating steel coils are produced by cold rolled GI steel which is coated with a layer of oil pait.After painted, the coils has beautiful appearance and more durable.

Technical specifications:

| Standards | GB/JIS/ASTM |

| Size range | Thickness:0.15-1.5mm, width:750-1000mm |

| Zinc coating | 40-75g/m2 |

| Coil ID | 508mm |

| Surface | Chromated/Un-oiled/Oiled/Dry |

| Spangle | Regular/Minimized/Big spangle |

| Coil weight | 2-12mt |

| Material | SGCC, DX51D,SGCH |

| Paint | Top side:17-25 micron, back side 5-10 micron |

| Color | RAL Chart, as per customer’ color swatch |

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork to form the main structure of the ducts. The steel coils are processed and shaped into specific sizes and dimensions, allowing them to be easily fabricated into duct sections. These coils provide strength and durability to the ductwork, ensuring it can withstand the high pressures and temperatures involved in HVAC systems.

- Q: I have a steel support beam can you remove one of the poles . the steel beam set on sender blocks on both side of the foundation. I have three steel beams support beam across the basement,I just want to remove one pole, can that be done.

- You need to measure the beam and go to an engineering guide and see what the load ratings are. You can never remove the end supports but the middle support may possibly be taken out if the beam can handle the load and or you add some gusseting and reinforcement to the original beam. You should probably call a building engineer to consult on this.

- Q: How do steel coils compare to other materials like aluminum or copper?

- Steel coils have distinct advantages over materials like aluminum or copper in certain applications. Steel is generally more affordable, readily available, and has higher tensile strength compared to aluminum or copper. It also offers better resistance to corrosion and is highly durable, making it suitable for heavy-duty applications. However, aluminum and copper have their own unique properties that make them preferable for specific uses, such as electrical conductivity or lightweight construction. Ultimately, the choice between steel coils and other materials depends on the specific requirements and intended application.

- Q: What are the different methods of stretch leveling steel coils?

- There exists a variety of methods for stretch leveling steel coils, each possessing their own unique advantages and applications. 1. Roller Leveling: This method entails passing the steel coil through a sequence of rollers that apply pressure to stretch and flatten the material. It is a widely utilized technique for leveling steel coils and grants excellent control over the leveling process. Roller leveling proves suitable for thin and medium gauge steel coils. 2. Tension Leveling: In this approach, high tension forces are applied to the steel coil via a set of bridle rolls. The tension aids in elongating and flattening the material, resulting in a level and stress-free coil. Tension leveling proves particularly effective for thicker and harder steel coils. 3. Laser Leveling: Laser technology is harnessed in this method to assess and rectify any imperfections present in the steel coil. A laser scanner diligently scans the surface of the coil and detects variations, which are subsequently adjusted by a laser beam. Laser leveling provides exceptional precision and is suitable for leveling delicate and high-value steel coils. 4. Stretcher Leveling: This method involves exceeding the yield point of the steel coil, leading to permanent deformation and the elimination of residual stresses. Stretcher leveling is commonly employed for heavy gauge coils and is capable of achieving substantial improvements in flatness. 5. Tensionless Leveling: As the name implies, tensionless leveling is executed without the application of tension to the steel coil. Instead, hydraulic or pneumatic pressure is employed to stretch and flatten the material. This method is ideal for delicate or sensitive steel coils that may be susceptible to damage under high tension forces. Each method of stretch leveling steel coils possesses its own set of advantages, such as control, precision, or suitability for specific types of steel coils. The selection of the appropriate method relies on factors such as the thickness, hardness, and quality requirements of the steel coil, as well as the desired flatness and surface finish.

- Q: and also what makes different hardness of stainless steel?

- The person above me is right .The stainless steel is used in shaving blades

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- If it has removable choke tubes, just get a MOD or IMP CYL and it will work. If it is a fixed choke, depending upon how old it is, the barrel may be too thing and steel could damage the barrel. If the shotgun is less than 20 years old and with a MOD or more open choke, you should be good to go.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances can vary depending on the specific industry and application. However, typical tolerances for coil thickness range from +/- 0.001 inches to +/- 0.005 inches.

- Q: What are common uses for steel coils?

- Common uses for steel coils include manufacturing automobiles, construction materials, appliances, pipes, and various industrial applications such as manufacturing machinery and equipment.

Send your message to us

Prepaintd galvanized steel coils Any color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords