Pre-Painted Galvanized Steel Sheet/Coil , High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

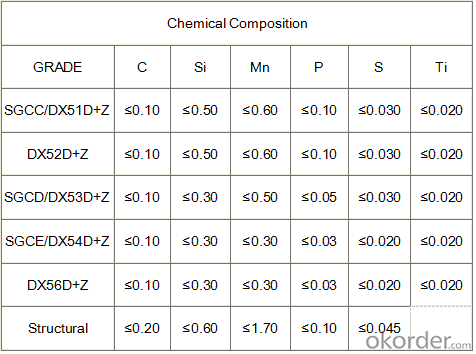

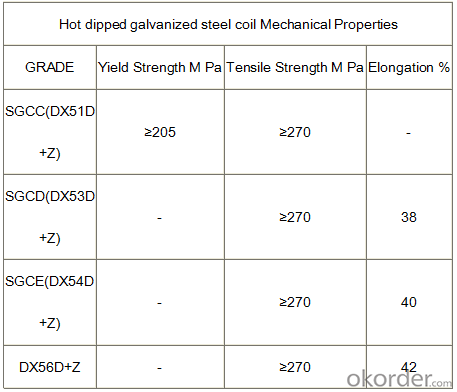

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: Where do I need hot galvanized steel coils and color coated rolls?

- The use of galvanized steel for color coated steel substrates, except zinc protection, organic coating on the zinc layer up covering the isolation effect, can prevent rusting steel, galvanized steel service life is longer, the coating steel plate galvanized steel long service life is 50%. However, the service life of the color coated plate with the same amount of zinc coating, the same coating and the same coating thickness will vary greatly in different regions and different parts.

- Q: I bought a damascus steel knife. It will be used for display. Nothing like hunting/skinning. If It is just sitting around, will it rust? (assuming that it isn't getting wet) Thanks for the help.

- From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material.

- Q: How are steel coils recycled?

- Steel coils can be recycled through a process that involves melting them down in a furnace, removing impurities, and then shaping the molten steel into new coils or other steel products. This recycling method helps conserve resources, reduce waste, and significantly cut down on energy consumption compared to producing steel from raw materials.

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Hi! well i hav both games but ther's no big difference. I play Diamond more though. For starter u shud pick piplup: 1. because u love water pokemon of course 2. piplup is stong against chimchar (water- fire) 3. it can learn ice moves like ice beam which are super effective against torterra. 4. Empoleon looks Wicked!! and its steel type backs up its weaknesses. i liked it. hav fun with the game!!!!!!!

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Molar Mass Steel

- Q: Can you weld copper or brass to steel?

- GTAW,Weld Copper to steel, RN-60. Silver Braze Copper to Steel, Grade 4 Silver.

- Q: How are steel coils used in the production of automotive suspension systems?

- Steel coils are used in the production of automotive suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically used in the construction of coil springs, which are then integrated into the suspension system to ensure a smooth and comfortable ride for the vehicle.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils used in the mining equipment industry can vary depending on the specific application and requirements. However, there are some common dimensions that are often used. Typically, the width of steel coils used in the mining equipment industry can range from 600mm to 2000mm or even wider. This allows for flexibility in the manufacturing process and ensures that the coils can be tailored to fit various equipment sizes and specifications. In terms of thickness, steel coils used in mining equipment can vary from 1.5mm to 20mm or more. The specific thickness is determined by factors such as the type of equipment, the intended use, and the level of durability required. The length of steel coils used in the mining equipment industry can also vary, but commonly falls within the range of 1000mm to 6000mm. Again, this allows for flexibility in the manufacturing process and ensures that the coils can be cut to fit the specific requirements of the equipment being produced. It is important to note that these dimensions are not set in stone and can be customized to meet the specific needs of the mining equipment industry. Manufacturers and suppliers in the industry are often able to provide coils in various sizes and dimensions to accommodate the diverse range of equipment used in mining operations.

- Q: Can steel coils be custom-made to specific requirements?

- Yes, steel coils can be custom-made to specific requirements. Steel manufacturers have the capabilities to produce steel coils with various dimensions, thicknesses, and specifications to meet the specific needs of customers. These coils can be customized in terms of width, length, weight, and even surface finish to suit specific applications and industries. Customization can also include variations in steel grade, coating type, and mechanical properties to ensure the desired performance and functionality. The ability to tailor steel coils to specific requirements allows for optimal utilization in various sectors such as automotive, construction, appliances, and manufacturing, among others.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil , High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords