Pre painted Galvanized Steel Coil with Lowset Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent heat resistance performance

• High strength

• Good formability

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Good visual effect

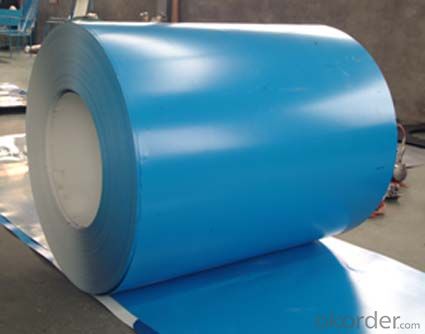

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: What are the typical lead times for ordering steel coils?

- The typical lead times for ordering steel coils can vary depending on various factors such as the type and size of the coil, the supplier's production capacity, and the current market conditions. However, on average, lead times for ordering steel coils can range from a few weeks to several months. For standard-sized steel coils that are readily available in the market, lead times are generally shorter and can range from a few weeks to a couple of months. This is because suppliers often maintain a stock of these commonly used coil sizes to meet immediate customer demands. However, it's important to note that lead times can still be influenced by factors like transportation and logistics. On the other hand, if you require custom-made or non-standard steel coils, lead times can be longer. These coils usually involve additional processes such as specialized cutting, shaping, or coating, which may require more time for production. Lead times for custom-made steel coils can range from a few months to even six months or more, depending on the complexity of the specifications and the supplier's production capabilities. It's worth mentioning that lead times can also be affected by external factors like market demand and availability of raw materials. During periods of high demand or when there are supply chain disruptions, lead times may be extended as suppliers need to adjust their production schedules accordingly. To accurately determine the lead times for ordering steel coils, it is recommended to reach out to specific suppliers or manufacturers. They will be able to provide you with the most up-to-date and accurate information based on your specific requirements and the current market conditions.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- - Find the cross sectional area of the steel bars if given, if not find the volume of concrete and approximately multiply the concrete volume by 400kg the weight of steel per concrete volume. - If you find the steel cross sectional area , multiply by the

- Q: How are steel coils processed and treated?

- To ensure the quality and suitability of steel coils for different applications, they undergo a series of steps and treatments. Initially, the coil is uncoiled by removing its protective wrapping and unwinding it. Any defects like cracks or uneven surfaces are then inspected. Next, the coil is cleaned to eliminate dirt, oil, and rust using chemical agents and mechanical scrubbing. After cleaning, it is rinsed and dried to prevent corrosion caused by residual moisture. Once cleaned, the steel coil may be treated based on its intended use. One common treatment is pickling, where the coil is immersed in an acidic solution to remove impurities and scale. This improves the surface finish and prepares the steel for further processing. After pickling, the coil can undergo cold rolling, which reduces its thickness and improves dimensional accuracy. This is done by passing the steel through a series of rollers at room temperature, gradually decreasing thickness and increasing strength. It also improves the surface finish. In some cases, the coil may undergo additional heat treatments like annealing or tempering. Annealing involves heating the coil to a specific temperature and slowly cooling it to relieve internal stresses and improve mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and rapidly cooling it to enhance strength and toughness. Once the desired processing and treatments are completed, the steel coil may be coated or painted for added protection against corrosion or to enhance its appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings like paint or powder coatings. Finally, the processed and treated steel coils are cut into specific sizes or shapes according to customer requirements. This can be done using cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide a high strength material that can be shaped and formed into various parts such as brackets, frames, and supports. These coils are typically processed and cut into the required sizes and shapes before being further fabricated and assembled into elevator components, ensuring the necessary structural integrity and durability for safe elevator operation.

- Q: What are the different types of steel coil surface treatments for durability?

- There are several types of steel coil surface treatments used to enhance durability. These include hot-dip galvanizing, electro-galvanizing, galvannealing, and organic coating. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc to create a protective zinc coating. Electro-galvanizing is a similar process, but it uses an electric current to deposit a layer of zinc onto the steel surface. Galvannealing combines the galvanizing and annealing processes to create a zinc-iron alloy coating that offers enhanced corrosion resistance. Organic coating involves applying a layer of paint or other organic material to the steel surface, providing protection against corrosion and enhancing aesthetics.

- Q: I mean about if I had a piece of metal, how can i decide that's iron or steel?Sorry for bad English.

- Iron and steel have different thermal expansions and specific heats. You could either heat it up and see how much it changes in length or you could put it in water inside a calorimeter and observe how much the temperature of the water changes

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- CS is a noxious gas that I have tasted. If it is spec mild steel then do so.

- Q: Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes. Barcodes can be printed or attached onto the surface of steel coils, allowing for easy identification, tracking, and inventory management.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through a series of visual and mechanical tests. Firstly, the external appearance of the coil is examined to ensure it is free from any visible defects such as dents, scratches, or rust. This is important as it ensures the coil's overall integrity and prevents potential issues during further processing. Next, the thickness of the coil is measured at various points using non-destructive testing techniques like ultrasonic or magnetic particle inspection. This helps identify any variations in thickness, which could affect the coil's overall quality and performance. Additionally, the width of the coil is measured using precision instruments to check for any deviations from the required specifications. This ensures that the coil is within the desired width range, which is crucial for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. This is typically done using weighing scales or load cells, ensuring that the weight is consistent and meets the required standards. In terms of internal inspection, steel coils are sometimes subjected to eddy current testing, a non-destructive method that detects surface and near-surface defects. This technique uses electromagnetic induction to identify any irregularities in the metal, enabling the identification of defects such as cracks, voids, or inclusions. Overall, a combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures that steel coils are thoroughly inspected for uniformity. These rigorous inspection processes help guarantee the quality and reliability of the coils, allowing them to meet the industry standards and customer requirements.

- Q: what is the porpose of preheating mild steel prior to welding

- :you could attempt welding with whats pronounced as a filler rod. you could weld with the a million/8 rod interior the welder stinger and by conserving the a million/sixteen rod in the different hand, upload it as you weld.

Send your message to us

Pre painted Galvanized Steel Coil with Lowset Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords