Pre-Painted Galvanized Steel Coil Sky Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

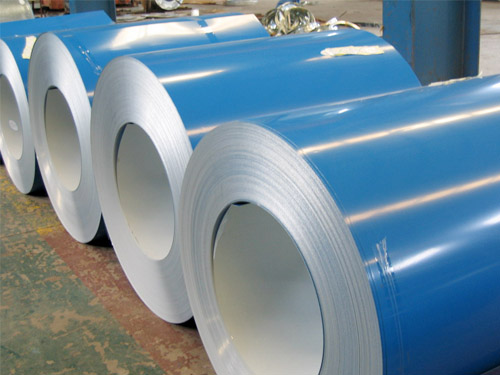

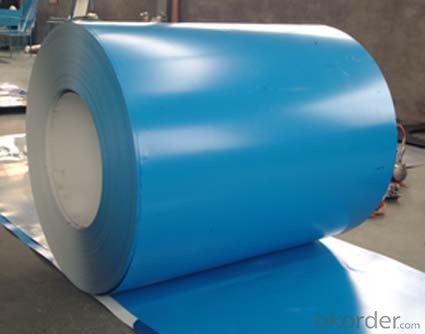

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the benefits of using coated steel coils in roofing applications?

- Using coated steel coils in roofing applications offers several advantages. Firstly, the steel coils are highly durable and provide excellent resistance against corrosion. The coatings act as a barrier, protecting the metal from moisture, chemicals, and harsh weather conditions. This ensures that the roofing system remains intact and functional for a long time, reducing the need for frequent repairs or replacements. Secondly, coated steel coils offer superior strength and structural integrity. Steel is known for its high tensile strength, and when combined with the protective coating, it becomes even more resilient. This makes coated steel coils an ideal choice for roofing applications, as they can withstand heavy loads, extreme temperatures, and strong winds without compromising the structure's integrity. Additionally, coated steel coils are lightweight, making them easy to handle and install. This saves time and effort during the roofing process and reduces the overall weight of the structure, minimizing stress on the building's foundation. Furthermore, coated steel coils come in a variety of colors and finishes, allowing for greater design flexibility. Architects and homeowners can choose from a wide range of options to enhance the building's aesthetics. The coatings also provide enhanced UV resistance, preventing color fading and ensuring the roofing system maintains its appearance over time. Lastly, using coated steel coils in roofing applications is an environmentally friendly choice. Steel is highly recyclable, and the coatings used on the coils can be formulated to be environmentally friendly as well. This reduces the carbon footprint associated with construction and promotes sustainability. In conclusion, the benefits of using coated steel coils in roofing applications include durability, strength, lightweight, design flexibility, and environmental sustainability. These advantages make coated steel coils a reliable and cost-effective choice for any roofing project.

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery primarily for the fabrication of structural components and parts such as frames, chassis, axles, and brackets. The high strength and durability of steel make it an ideal material for these applications, ensuring the machinery can withstand the harsh conditions and heavy loads typically encountered in agricultural operations. Steel coils are processed and formed into the required shapes and sizes to create sturdy and reliable components that contribute to the overall performance and longevity of agricultural machinery.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Yeah you awaken after the ending cutscene in case you have it put in and then yet another quest line is given to you and you will circulate on your merry way doing in spite of you experience like.

- Q: How are steel coils used in the production of HVAC ducts?

- HVAC duct production relies heavily on steel coils, which are vital for their construction. These coils, typically composed of galvanized steel, possess the qualities of strength, durability, and corrosion resistance. To create the necessary flat sheets, the steel coils undergo an initial unwinding and flattening process. These sheets are then cut into specific sizes and shapes in accordance with the design and dimensions of the HVAC ducts. Additionally, the steel coils are subjected to various machines, such as shearing, slitting, and roll forming machines, to achieve the desired shapes and sizes for the ducts. Once transformed into the appropriate shapes, the steel coils are further processed to add additional features to the ducts. This can include bending, folding, or welding processes to create bends, angles, or connections in the ductwork. These processes allow for customization, ensuring that the ducts perfectly fit the specific requirements of the HVAC system and the building structure. Moreover, steel coils play a crucial role in maintaining the strength and integrity of HVAC ducts. The galvanized steel used in the coils provides a protective layer that prevents rust and corrosion, resulting in more durable and long-lasting ducts. This is particularly significant as HVAC ducts are regularly exposed to various environmental factors such as moisture, temperature changes, and airborne contaminants. In summary, steel coils are an essential and fundamental component in the production of HVAC ducts. They not only provide the necessary strength, durability, and corrosion resistance but also offer flexibility and customization in the manufacturing process.

- Q: What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- I, too, don't like stainless steel because it is so hard to keep clean. Bar Keeper's Friend really does become your friend when you cook on stainless steel. It will remove the burnt on food, remove the dark brown stains and keep it looking new, however. And, it won't void most manufacturer's warranties on the cookware. It just takes the elbow grease to do it every time you use it. I found it is necessary to use more olive oil than you think is necessary, a lower flame than most recipes call for and a lot of patience if you plan to use it on a daily basis. I went back to my non-stick Calphelon because I am not a patient woman, I like instantaneous gratification and hate scrubbing pots and pans!

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings in several ways. Firstly, steel coils are used in the construction of insulated panels and roofs, which provide effective thermal insulation. This insulation helps to reduce heat transfer, keeping the interior of the building cool in hot weather and warm in cold weather. Additionally, steel coils are often used in the manufacturing of energy-efficient windows and doors. These windows and doors are designed to minimize heat loss or gain, thereby reducing the need for heating or cooling systems and saving energy. Furthermore, steel coils are also utilized in the production of energy-efficient appliances, such as refrigerators and air conditioners, which consume less electricity while providing the same level of performance. Overall, the use of steel coils in building construction and appliances contributes to improved energy efficiency, reducing energy consumption and promoting sustainability.

- Q: What are the common welding methods used for steel coils?

- The common welding methods used for steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they provide the raw material for creating structural components such as beams, girders, and columns. These coils are processed and shaped into the required sections, which are then assembled and welded together to form the bridge's framework. The strength and durability of steel make it an ideal material for constructing bridges that can withstand heavy loads and harsh environmental conditions.

- Q: I want to make a stock removal knife, but I am really confused about what steel to use. I am just a beginner but I read o1 steel is great? Also I am kind of on a budget.

- 01 tool steel is easier to work with. You need to contact places like Pop Knives and Supplies out of Washington, Georgia or Sheffield Steel out of Florida, I made custom knives for years with my husband. Made alot with ATS-34 Stainless. Look at links on my website source.

Send your message to us

Pre-Painted Galvanized Steel Coil Sky Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords