Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality ,Orange Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

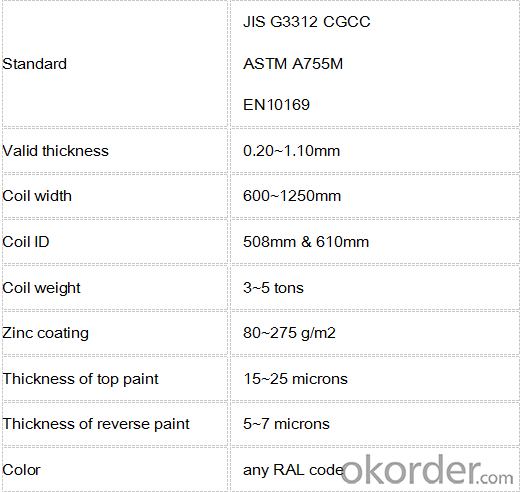

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including polyester, polyurethane, siliconized polyester, fluorocarbon, and plastisol coatings. Each type of coating offers specific properties and benefits, such as durability, corrosion resistance, weatherability, and aesthetics, making them suitable for various applications in industries such as construction, automotive, and appliances.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Paint adhesion on steel coils is systematically and rigorously inspected using adhesion testers. These testers are specifically designed devices for assessing the bond strength between the paint and the underlying steel surface. To begin the inspection process, representative samples are selected from the steel coils. These samples are typically cut into smaller sections to ensure they are free from defects or surface irregularities that could impact the adhesion test results. Once the samples are prepared, the adhesion testers are utilized to measure the force needed to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. It consists of a set of blades arranged in a grid pattern, which are employed to create cuts through the paint coating, forming a grid of squares or rectangles down to the steel surface. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface, and the force required for the paint coating's removal from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could result in issues like paint delamination or corrosion. Along with the cross-cut adhesion tester, other adhesion testing methods may also be utilized, such as the pull-off adhesion tester. This method involves a hydraulic or mechanical device applying a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. In summary, the use of adhesion testers ensures a thorough inspection of paint adhesion on steel coils. This process helps in early identification of potential adhesion issues, enabling appropriate remedial measures to be taken to ensure the durability and performance of the paint coating.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The dimensions of steel coils used in the power generation industry can vary depending on the specific application and requirements. However, in general, steel coils for power generation are typically available in various sizes and thicknesses. The width of steel coils used in power generation can range from a few inches to several feet, depending on the specific equipment or machinery they are intended for. These coils are often designed to fit specific manufacturing processes or components within power generation systems. The thickness of steel coils used in the power generation industry can also vary significantly. Thicker coils are commonly utilized for heavy-duty applications that require increased strength and durability, while thinner coils may be suitable for less demanding tasks or where weight reduction is a priority. Additionally, the weight of steel coils used in power generation can vary depending on their dimensions and the specific steel material being used. The weight is an essential consideration during transportation, installation, and handling of the coils. It is important to note that the dimensions of steel coils used in the power generation industry can be customized to meet specific project requirements. Manufacturers typically work closely with power generation companies to understand their needs and provide tailored solutions that meet their dimensional specifications.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, some common dimensions for steel coils used in this industry are typically around 3 to 5 feet in width and 10 to 15 feet in length. The thickness of the steel coils can vary as well, ranging from 0.01 to 0.5 inches. It is important to note that these dimensions are not fixed and may vary based on the specific needs of the railway equipment industry, such as the type of equipment being manufactured or the specific function of the steel coils.

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as the primary raw material for creating various components such as frames, chassis, and heavy-duty structures. These coils are often cut, shaped, and welded to form the necessary parts, providing strength and durability to the equipment. The malleability and strength of steel make it an ideal material for construction equipment, ensuring their ability to withstand heavy loads and harsh working conditions.

- Q: How are steel coils used in the production of metal storage systems?

- Steel coils are used in the production of metal storage systems as the primary raw material. These coils are processed and shaped into the desired forms, such as sheets, panels, or beams, which are then assembled to create sturdy and durable storage systems capable of safely storing various items.

- Q: What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils vary depending on the specific industry and application. However, some of the most common coil diameters for steel coils typically range from 24 inches to 72 inches. These diameters are often used in various sectors such as automotive, construction, and manufacturing. It is important to note that the specific coil diameter required may differ based on factors such as the size and weight of the material being coiled, the equipment being used to handle the coils, and the specific requirements of the end-use application.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: I had a damascus steel katana made for me and was wondering if I could put gun blue on it to make the steel black and it still work right

- There are many makers that use blue on there Damascus. My question, what the heck are you wanting to mess with the finish for? If you had a true Damascus blade made that that thing cost a fortune, and I don't mean under a grand either. Then there is the question of what it is made from, some steel combinations react well to the gun blue, others not so much. If it is a stainless blade it won't work at all and you shouldn't be using it either. I can tell you, my Damascus blades start at $100 for a small cable knife and go up from there. If you wanted a sword it would push 10 g's easy. None of my customers would mess with the finish, most would cry if it got scratched. If it's has a pretty pattern don't mess with it.

- Q: How are steel coils distributed globally?

- Steel coils are distributed globally through various means such as shipping, rail, and truck transportation. They are typically transported in bulk quantities to steel processing plants, construction sites, and manufacturing facilities worldwide. Distribution channels and logistics networks play a crucial role in ensuring efficient and timely delivery of steel coils to meet the demands of different industries and markets across the globe.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality ,Orange Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords