Pre- painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• nice formability

• Good visual effect

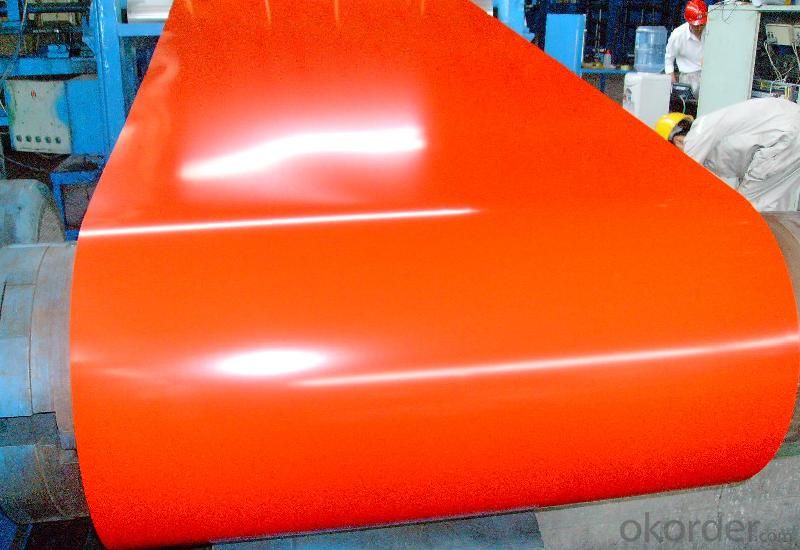

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available...

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils offer several advantages. Firstly, they have a higher strength-to-weight ratio, making them suitable for applications that require strong and durable materials. Secondly, hot-rolled steel coils have better formability, allowing for easier shaping and manipulation during fabrication. Additionally, these coils have a smoother surface finish, making them more aesthetically appealing and suitable for applications that require a polished appearance. Lastly, hot-rolled steel coils are generally more cost-effective compared to other steel manufacturing processes, making them a preferred choice for various industries.

- Q: How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they are rolled into flat sheets and then cut into various sizes and shapes. These steel sheets are then formed, fabricated, and installed to create the outer layer of a building. The steel coils provide strength, durability, and a sleek, modern appearance to the facades, making them an essential component in the construction industry.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: What are the different types of steel coil coatings for heat resistance?

- There are several types of steel coil coatings available for heat resistance. These coatings are designed to protect the steel surface from high temperatures and prevent oxidation or degradation. One common type of coating is the organic coating, which is typically made of epoxy, polyester, or polyurethane. These coatings provide a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are often used in applications where moderate heat resistance is required. Another type of coating is the inorganic coating, which is typically made of ceramic or metallic materials. These coatings provide excellent heat resistance and can withstand extremely high temperatures. Inorganic coatings are commonly used in industries such as automotive, aerospace, and power generation, where components are exposed to intense heat. There are also specialized coatings available for specific heat resistance requirements. For example, silicone coatings provide exceptional heat resistance and can withstand temperatures up to 600°C (1112°F). These coatings are commonly used in applications such as exhaust systems, ovens, and industrial furnaces. Additionally, some steel coil coatings may contain additives or fillers to enhance their heat resistance properties. These additives can improve the coating's ability to withstand high temperatures and provide better protection against heat-related issues. In summary, there are various types of steel coil coatings available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application, and factors such as temperature range, duration of exposure, and environmental conditions should be considered when selecting the appropriate coating.

- Q: What are the different methods of laminating steel coils?

- There are mainly three methods of laminating steel coils: the hot-dipped galvanizing method, the electro-galvanizing method, and the cold-rolled laminating method. The hot-dipped galvanizing method involves dipping the steel coils into a bath of molten zinc, which forms a protective layer on the surface. The electro-galvanizing method uses an electric current to deposit a thin layer of zinc onto the steel coils. Lastly, the cold-rolled laminating method involves pressing together layers of steel with an adhesive layer in between to create a laminated coil. These methods help enhance the durability, corrosion resistance, and overall quality of the steel coils.

- Q: What are the different types of steel coil packaging materials?

- Some common types of steel coil packaging materials include wooden crates, steel frames, plastic strapping, stretch wrap, and steel bands.

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Steel wheels were not available on the pickups until 1929. The cars had the options of steel disc or wood spoke wheels in the mid '20's. I'm pretty sure that '27 was the last year the wood wheels were available on passenger cars.

- Q: What is the difference between hot-rolled and cold-rolled steel coils?

- Hot-rolled steel coils are produced at high temperatures, resulting in a rough surface and less precise dimensions. Cold-rolled steel coils, on the other hand, are processed at lower temperatures, leading to a smoother surface and more accurate dimensions.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- Say The radius of steel ball is R. Its shell is t thick so the air filled cavity if of radius r where r = R - t Steel has a density p The mass of the ball m is given m = 4/3 pi (R^3 - r^3) p If the ball is just to float then the mass dived by the must equal the density fo water d d = m / 43/ pi R^3 Equating m in the above equations yields (r/R)^3 = (p - d)/p or r = c R where c =((p-d)/p))^1/3 Using above leads to m = 4/3 pi R^3 (1 - c^3) p and hence R can be solved for So taking p (density of steel) 490 lb/ft^3 and d (density of water) at 62 lb/ft^3 yields c= 0.9557 Applying the equation above gives R = 1.565 ft or a diameter of 37.55 in The shell thickness is R (1 - c) or 0.06938 ft or 0.8327 in Note I do all my work in metric units so I had to do some conversions on the run. I hope you will check things to make sure the maths is correct. Anyway good luck

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

Send your message to us

Pre- painted Galvanized/ Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords