Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI Steel Coil Images

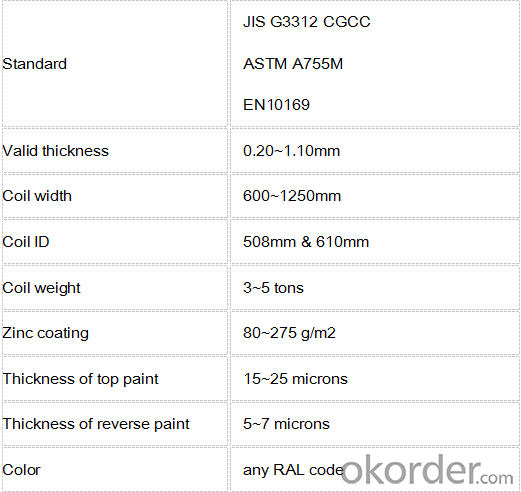

4.Pre-painted GI Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different coil slitting methods used for steel coils?

- There are three main coil slitting methods used for steel coils: rotary shear slitting, loop slitting, and oscillating slitting. Rotary shear slitting involves using rotating knives to cut the steel coil into narrower strips. Loop slitting is a process where the coil is looped through a series of rolls, and the desired width is achieved by adjusting the tension in the loop. Oscillating slitting is another method where the steel coil is passed through a set of oscillating blades, resulting in precise and high-speed slitting. These methods offer various advantages and are chosen based on the specific requirements of the steel coil slitting process.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- Yes, OK for steel. Like Mr. 357 says, with steel shot one size more open is equal to the one size tighter. So the Modified should shoot like a full choke and your improved cylinder should pattern like a modified choke. The Express model came out about the same time steel shot became prevalent and it is fine with steel shot. If I remember correctly we were working on making the data sheets for steel shot around 1988-1989. My hunting buddy and neighbor was the man who first began importing steel shot. Had to figure out a wad to use with it also. And got it Federally mandated for waterfowl hunting.

- Q: How do steel coil manufacturers handle product recalls?

- Steel coil manufacturers handle product recalls by following a systematic process to ensure the safety and satisfaction of their customers. Here is an outline of the steps involved in handling product recalls: 1. Identification of the issue: Once a potential problem or defect is discovered in the steel coils, manufacturers initiate the recall process. This may be due to a quality control failure, safety concern, or non-compliance with industry standards. 2. Investigation and evaluation: The manufacturer investigates the root cause of the problem and evaluates the potential impact on customer safety and satisfaction. They analyze the affected batch or production run to determine the extent of the issue. 3. Notification: Manufacturers promptly notify customers who have purchased the affected steel coils. They use various channels, such as direct mail, email, phone calls, or public announcements, to inform customers about the recall. The notification includes specific details about the problem, potential risks, and instructions on how to proceed. 4. Retrieval and replacement: The manufacturer provides instructions on how customers can return or dispose of the recalled steel coils safely. They may offer options for product retrieval, such as direct pick-up from the customer's location or designated drop-off points. In some cases, manufacturers may provide replacement steel coils or reimburse customers for the affected products. 5. Public communication: Steel coil manufacturers issue public statements and notifications to inform the wider market, distributors, and retailers about the recall. This ensures that all stakeholders are aware of the issue and can take appropriate actions to address it. 6. Corrective actions: After retrieving the recalled steel coils, manufacturers implement corrective actions to rectify the issue. This may involve improving their quality control processes, upgrading manufacturing equipment, or revising product specifications to prevent future recalls. 7. Customer support: Throughout the recall process, manufacturers provide customer support to address any concerns, questions, or complaints. They establish dedicated hotlines, email addresses, or online portals to assist customers with their inquiries and guide them through the recall process. 8. Regulatory compliance: Steel coil manufacturers ensure compliance with relevant regulatory authorities and standards organizations during the recall process. They work closely with regulatory agencies to provide necessary information, documentation, and updates to address any legal requirements. Overall, steel coil manufacturers prioritize customer safety and satisfaction when handling product recalls. They follow a well-defined process that involves identification, investigation, notification, retrieval, replacement, public communication, corrective actions, customer support, and regulatory compliance. Through these steps, manufacturers aim to rectify the issue, prevent harm, and maintain trust with their customers.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- This Site Might Help You. RE: Whats better chrome vanadium steel or carbon stainless steel? I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they provide the raw material for creating the manifold's structural components. These coils are typically cut, shaped, and welded to form the intricate and durable design required for efficient exhaust gas flow.

- Q: How are steel coils inspected for impact resistance?

- Steel coils are typically inspected for impact resistance using various methods to ensure their durability and ability to withstand external forces. One common method is the drop test, where a steel coil is dropped from a specified height onto a hard surface. This test simulates the impact that the coil may encounter during transportation or handling. During the drop test, the coil is visually inspected for any visible signs of damage, such as dents, cracks, or deformations. Additionally, the coil may undergo further examinations, such as ultrasonic testing or magnetic particle inspection, to detect any hidden internal defects that could compromise its impact resistance. Another method used to inspect steel coils for impact resistance is the pendulum test. In this test, a pendulum with a known weight and height is swung and impacts the coil's surface. The energy absorbed by the coil during the impact is measured, and this data is used to evaluate its resistance to impact. Furthermore, steel coils may undergo laboratory tests, such as Charpy impact testing, to determine their resistance to sudden impacts. This test involves striking a notched sample of the coil with a pendulum hammer, measuring the amount of energy absorbed by the sample, and evaluating its impact strength. Overall, a combination of drop tests, visual inspections, non-destructive testing methods, pendulum tests, and laboratory tests are used to inspect steel coils for impact resistance. These inspections ensure that the coils meet the required standards and can withstand the potential challenges they may encounter during transportation, storage, and use.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- There are several types of steel coil surface treatments suitable for outdoor applications. These include galvanization, which involves coating the steel with a layer of zinc to protect against corrosion; zinc-aluminum alloy coating, which provides enhanced corrosion resistance; paint coating, which adds a layer of protective paint to the steel surface; and organic coating, which uses a polymer-based material to protect against weathering and corrosion.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: Are steel coils used in automotive manufacturing?

- Yes, steel coils are commonly used in automotive manufacturing. They are used to produce various components such as body panels, chassis parts, and structural reinforcements due to their strength, durability, and formability.

- Q: What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps. First, the steel coils are collected from various sources, such as manufacturing and construction sites. Next, the coils are transported to a recycling facility where they undergo a thorough inspection and sorting process. The coils are then cleaned to remove any contaminants or impurities. After cleaning, the steel coils are shredded into smaller pieces and melted down in a furnace. The molten steel is then molded into new coils or other steel products. Finally, the recycled steel coils are tested for quality and can be used in various industries, reducing the need for new steel production and minimizing waste.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Best Price Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords