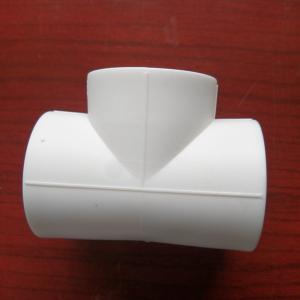

Plastic Air Pipe Fittings for PPR Tee Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPR Tee Plastic Pipe Fittings

Mainly used to connect civil construction, industrial, agricultural and landscape irrigation drainage system PE pipes

Main Features of PPR Tee Plastic Pipe Fittings

Mainly used to connect civil construction, industrial, agricultural and landscape irrigation drainage system PE pipes

1, health, non-toxic: the various parts of the pipeline system consists of PP-R pipes and fittings constituted can be completely non-toxic, health indicators in line with GB / T17219 standards.

2, does not rust: PH value can withstand a wide temperature range, in the range of 1 to 14, a high concentration of acid and alkali corrosion.

3, wear-resistant, non-fouling: PP-R pipe and tube inner wall smooth, uniform flow resistance is small and does not scale.

4, reducing vibration and noise: PP-R pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

5, anti-cracking: PP-R materials excellent elasticity makes pipes and fittings sectionally With frost expansion of the liquid together without bursting.

6, anti-condensation, heat loss is small: PP-R material is a poor thermal conductor, reduces condensation and reduce heat loss less.

7, anti-electric corrosion: PP-R material is a poor conductor of electricity can avoid corrosion. Complete specifications: 10-30 optional

Pictures of PPR Tee Plastic Pipe Fittings

- Q: Are plastic pipe fittings as durable as metal pipe fittings?

- Plastic pipe fittings are generally not as durable as metal pipe fittings. While they can be more affordable and resistant to corrosion, plastic fittings are more susceptible to cracking, breaking, and degradation over time. Metal pipe fittings, on the other hand, offer greater strength, longevity, and resistance to physical damage.

- Q: Can plastic pipe fittings be used for stormwater drainage?

- Yes, plastic pipe fittings can be used for stormwater drainage. Plastic pipes and fittings are commonly used in stormwater drainage systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and low-maintenance compared to other alternatives.

- Q: Are plastic pipe fittings resistant to soil chemicals?

- Yes, plastic pipe fittings are generally resistant to soil chemicals.

- Q: Are plastic pipe fittings suitable for both residential and commercial applications?

- Yes, plastic pipe fittings are suitable for both residential and commercial applications. They are commonly used in both settings due to their durability, affordability, and ease of installation. Additionally, plastic pipe fittings are resistant to corrosion and chemicals, making them a reliable choice for various plumbing needs in both residential and commercial buildings.

- Q: How do you connect plastic pipe fittings to CPVC pipes?

- To connect plastic pipe fittings to CPVC pipes, you can use solvent cement specifically designed for CPVC. Clean both the fittings and pipes thoroughly, apply the solvent cement to the inside of the fitting and the outside of the pipe, and then insert the pipe into the fitting, holding it in place for a few seconds. Allow the cement to dry and cure as per the manufacturer's instructions before applying pressure to the joint.

- Q: Can plastic pipe fittings be used for chemical refineries?

- No, plastic pipe fittings are generally not suitable for chemical refineries as they may not be able to withstand the corrosive and high-temperature environments typically present in these facilities.

- Q: Are plastic pipe fittings suitable for irrigation systems?

- Yes, plastic pipe fittings are suitable for irrigation systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for outdoor applications. Additionally, plastic fittings are easy to install, cost-effective, and provide reliable performance in various weather conditions.

- Q: How do you connect plastic pipe fittings to polybutylene pipes?

- To connect plastic pipe fittings to polybutylene pipes, you can use push-fit fittings specifically designed for polybutylene piping. These fittings have a built-in grip ring that securely holds onto the pipe when it is pushed into the fitting, creating a watertight seal. No additional tools or soldering are required, making it a quick and easy method for connecting plastic pipe fittings to polybutylene pipes.

- Q: Can plastic pipe fittings be used in chemical injection systems?

- Yes, plastic pipe fittings can be used in chemical injection systems. They are commonly used due to their resistance to chemical corrosion and compatibility with a wide range of chemicals. Additionally, plastic fittings offer ease of installation, durability, and cost-effectiveness, making them a suitable choice for many chemical injection applications. However, it is essential to ensure that the specific plastic material used is compatible with the chemical being injected to avoid any potential chemical reactions or degradation.

- Q: Do plastic pipe fittings have a maximum operating flow rate?

- Yes, plastic pipe fittings do have a maximum operating flow rate. The maximum flow rate is determined by the size and design of the fitting, as well as the type of plastic material used. Exceeding the recommended flow rate can lead to pressure loss, leaks, or even failure of the fitting. It is important to consult the manufacturer's specifications or guidelines to ensure proper usage and avoid any potential issues.

Send your message to us

Plastic Air Pipe Fittings for PPR Tee Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords