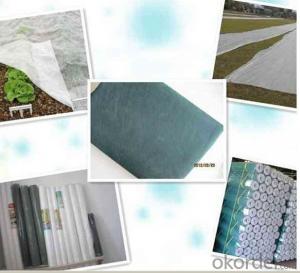

6 Oz PP Spunbonded Nonwoven Geotextile White

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FAQ :

1.What is your main products ?

Our main products are made from PE ,PP etc and could be used for agriculture and construction ,etc .

2.What is your payment term ?

We could accept TT ,LC.

3.What is your delivery time ?

The delivery time is around 30days per container, sometimes we have stocks .

pp spunbonded nonwoven fabric

Material

100% Polypropylene/100% PP

Color:Any color can be available

GSM(gram per square meter)

9-180GSM

Roll Width 4-320cm

Roll Length According to your requirement

Technics Nonwoven Spunbonded

Feature Waterproof, Mothproof, Eco-friendly, Non-toxic, Breathable, Anti-Bacteria

Usage Agriculture, Indrustry, Construction, Packaging,, Home-textitle, etc

Details

1MOQ 1 Ton

2 Loading Capacity

20’ Contain: 4 Tons

40’ HQ: 10-11 Tons

3Delivery Time

Within 7-15 days after 30% deposit is received or L/C

4 Payment Terms

1) T/T: 30% T/T in advance and balance 70% before shipping B/L copy

2) L/C at sight

1 Free Samples

2 Factory Supply

3 Competitive Price With High Quality

4 More than 20 years experience

- Q: How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents the transportation of sediment. They are used to stabilize soil and prevent erosion, allowing water to pass through while trapping sediment and silt. This helps in controlling sediment runoff, reducing soil erosion, and protecting water quality in various construction and environmental projects.

- Q: What are the specifications for geotextiles in coastal protection projects?

- The specifications for geotextiles in coastal protection projects typically include factors such as the material type, strength, permeability, and durability. The geotextiles used should be made of high-quality synthetic fibers, such as polypropylene or polyester, to withstand the harsh coastal environment. They should have sufficient tensile strength to resist erosion and provide stability to the project. The permeability of the geotextiles is crucial to facilitate proper drainage and prevent the buildup of water pressure. Additionally, the geotextiles should have excellent resistance to UV degradation and chemical exposure to ensure long-term performance in coastal conditions.

- Q: How to apply geotextile soil

- General geotextile cloth in the drainage layer above the geotextile covered with soil

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- To achieve the desired health, filter the effect of water, must be geotextile, only to cope, it can only be plastic film friends

- Q: Whether the non-woven geotextile is required for inspection

- Check, you go to 4 square meters to bring it, do not take the head, the standard horizontal and vertical

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. Geotextiles provide several benefits such as soil stabilization, erosion control, and drainage management, which are important for maintaining the integrity and performance of golf courses.

- Q: Reinforced geotextiles and composite soil is not the same

- Reinforced geotextile is from its use up, played a role in reinforcement, called reinforced geotextile. Composite geotextile refers to the process, is woven and non-woven acupuncture geotextile, through the acupuncture together with the geotextile. In other words, the ordinary non-woven acupuncture geotextile and composite geotextile in the use of if it is used to reinforced, can be called reinforced geotextile. Huazhi geotextile material manufacturers

- Q: What are the applications of geotextiles in road construction?

- Geotextiles have numerous applications in road construction, primarily in the areas of soil stabilization, drainage, and erosion control. They are used as a separation layer between the subgrade and the base course to prevent the mixing of different soil layers, thereby enhancing the stability and longevity of the road. Geotextiles also aid in improving the drainage system by allowing water to flow through the fabric while preventing soil particles from clogging the drainage system. Furthermore, they are employed to control erosion by preventing soil erosion from embankments and slopes, thereby maintaining the integrity of the road structure. Overall, geotextiles play a crucial role in enhancing the performance and durability of roads.

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil slopes when used in conjunction with geogrids. They help to distribute loads, reduce soil erosion, and improve drainage, which ultimately enhances the performance and longevity of the reinforced slope system.

- Q: What does geotextile mean?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. First, the characteristics: 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain full strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience, as the material light, soft, so the delivery, laying, construction convenience. 6, complete specifications: width of up to 9 meters. Is currently the widest product, the unit area quality: 100-1000g / ㎡. Second, the role: 1, isolation 2, filtration 3, drainage 4, reinforced 5, protection 6, anti-puncture

Send your message to us

6 Oz PP Spunbonded Nonwoven Geotextile White

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords