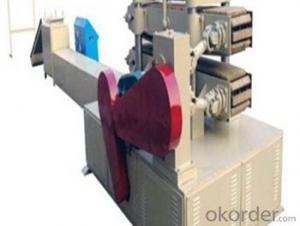

PP-RPEPPPE-RT Pipe Production extruder Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP-R\PE\PP\PE-RT Single Layer and Multi-layer Pipe Production Line

PP-R\PE\PP\PE-R Cold/Hot Water Pipe Production Line is mainly used to produce pipes of various diameters and thickness, which are used in various fields such as water supply system, industrial water conveying system, compressed air transportation, etc.

During the developing history, the PP-R\PE\PP\PE-RT pipe is the latest product, has the advantages of low prices, innocuity, non-corrosion, high temperature resistance and convenient to operate, etc.

This production line is developed by company on the basis of absorbing the international advanced technology, the important parts of screw and die head are specially designed according to the properties of PP-R\PE\PP\PE-RT material.

The electrical control uses frequency control, all the main electric parts are imported famous brand products; the total production line has the advantages of high output, stable quality, small deviation of the products, etc. therefore, it is the first-rate equipment in the plastic machinery industry. Meanwhile, this production line is suitable to produce the PP-C, PE-X cross-link pipe and the polyolefin pipes. Our company will offer formula, crafts and turn-key project.

This production line adopts two or three extruders co-extrusion crafts, uses PP-R\PE\PP\PE-RT as main material, and glass fiber in the middle layer.

This glass fiber intensified pipe has the advantages of high tenacity and strength, can withstand high inner and outer pressure; the pipes also overcomes the weak points that the pipe is easy to go bending and deforming.

Our company has successfully enlarged the worldwide markets for this production line, such as Pakistan, Bangladesh, etc.

And in China, this production line are warmly welcomed by more and more plastic manufacturers, the pipe market is becoming larger and larger.

Technical parameters:

Model Specifications. | SG-63 | SG-110 |

Produced Pipe Specification(mm) | φ20-φ63 | φ75-φ110 |

Production Line Speed(m/min) | 0.5-8 | 0.3-2 |

Total Power(kw) | 100-185 | 145-225 |

Note: The specifications are subject to change without prior notice.、

- Q: PPO plastic mold commonly used steel processing?

- Application range6 polyphenylene ether is high strength engineering plastics development 60s of this century, it has high mechanical strength and creep resistance; excellent electrical properties, high temperature to 120 DEG C, and in a wide temperature range, stable size, mechanical properties and electrical properties change little; absorption of water vapor is very small. Cooking. Widely used in electronic, electrical components, medical equipment, cameras and office equipment, and so onCommon problem7 injection molding process characteristics and process parameters of modified polyphenylene oxidePolyphenylene oxide (also known as: polyphenylene oxide) [PPO] has good chemical stability, low creep, aging resistance, and it is not easy to burn. Because of its good water resistance, polyphenylene oxide is widely used as an engineering plastic.The major disadvantages of polyphenylene oxide are: poor flowability of melt, difficulty in forming process, tendency of cross linking, expensive price, easy stress cracking and unstable impact strength.

- Q: How many venues will it take? How much does it cost?That's what recycling plastic bottles break. Sell again.What's the machine and how much does it cost? What should be done after breaking? If you make a semi-finished product, you can't sell it wellIs there any profit on this line?

- Low profits, hard death, can not make a few money

- Q: What is the function of adding filler in the processing of plastic products?

- 1., increase the strength: with glass fiber, can greatly increase the mechanical properties of plastics, tensile strength, bending strength, impact strength2., reduce costs: without reducing the strength of plastic, the addition of some fillers, such as talc, calcium carbonate, etc., can reduce the cost of plastics, but also increase the strength of the role.3., flame retardant effect: add flame retardant can be made into refractory plastic products.4. anti-aging: the addition of antioxidants can increase the anti-aging properties of plastics.5. lignite wax: to improve the flow of plastic, improve injection molding effect.

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: What do you understand in the early stage and how much equipment are needed for the preparation?. Thank you

- Then don't do it. Baidu can't support you in such a big deal. Because big bosses rarely disclose business experience on Baidu - find a reliable master or technician and learn from it

- Q: I do not know the classification details and processing procedures, as well as the purchase of such equipment, the need for experienced master guidance, you can also join the cooperation,

- Different kinds of waste plastics have different characteristics. As far as impurity content is concerned, waste materials in the middle and outer corners of the factory produce impuritiesThe content of less than 0.1%, piled up scrap for a period of time and other products used for% impurity content 0.1 ~0.5%, mixed with aluminum, cloth and paper composite plastic waste impurities are often more than 10%. For used waste plastics,According to different use conditions, will include ultraviolet radiation, heat, oxygen aging effect, pollutants.Ring. For different shapes of waste plastics, the volume density of materials after crushing is very different, film, sheet, flatThe volume density of the crushing material is smaller, which is a problem that must be considered in the process of waste plastics recycling and granulation.Two. Pretreatment of waste plasticsFrom discarded packages, such as bags, shopping bags, bottles, cans, boxes and waste agricultural film waste plastics, inPretreatment prior to granulation. The pretreatment process mainly includes classification, cleaning, crushing and drying.Classification work is the classification of miscellaneous waste plastics products according to the type of raw materials and product shapes classification. By raw materialsClass sorting requires operators to have a good knowledge of identifying plastic varieties, and the purpose of sorting is to avoid different speciesThe resulting polymers are incompatible with recycled materials and have poor performance. They are classified according to the shape of the product to facilitate the use of waste plasticsThe crushing process can be carried out smoothly, because the film, flat and fabric used in crushing equipment with some thick and hard wareThe crushing equipment often can not replace each other.

- Q: What plastic products can ABS be used for?

- 4. office equipment ABS has excellent impact resistance, good dimensional stability and rigidity. Forming, housing for manufacturing all kinds of office equipment, economic and practical. Such as fax machines, photocopiers, typewriters and computer monitors and other office equipment. The higher requirement on the fire, so usually are made of flame retardant ABS grade manufacturing.5. die model because ABS plastic machining performance, light weight, low price, in recent years has been widely used to mold model making industry, automobile, electronic appliances, machinery and equipment testing instrument. The rapid forming machine model Dimension is currently the world's most advanced ABS manufacturing standard stereo prototype as raw materials, then you can test of new product appearance, suitable degree and related functions. With the best price in similar products.

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- You send the amount of plastic parts should refer to the use of injection molding mold design, injection molding parts need to know the relevant knowledge of mold structure, mold design or you out of difficult processing, or even can be processed but need to increase the cost a lot of plastic design with rubbing wear and broken, less inclined to top. That will increase the cost of.

- Q: what kind of machines, where to buy, how much money should be invested?

- What time I plant, to provide technical support, the purchase of machinery recommendation.

- Q: What kind of machine does plastic products factory use to produce plastic products?.

- Plastic and metal crafts of mass production are painted on the surface, generally divided into paint (pigment), color and polishing, color, usually by spraying, coloring and electroplating coloring.

Send your message to us

PP-RPEPPPE-RT Pipe Production extruder Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches