Naue Geotextile PP Plastic Animal Fence from Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

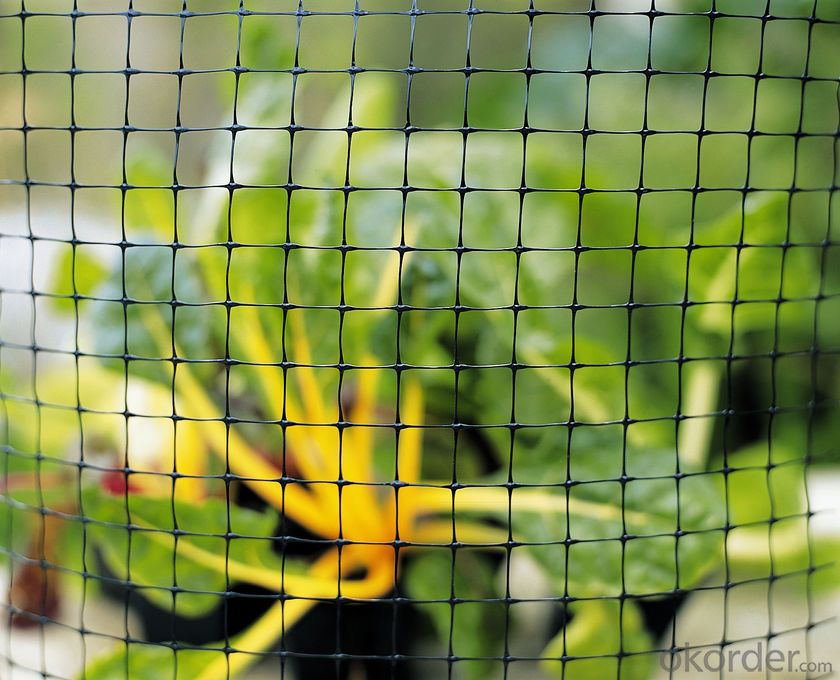

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

4. Deer Fence Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

5. Package/Payment/Delivery:

Package: Usually packed by rolls in plastic film bags with labels inside and then loosely loaded in the container

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What can the geotext crushed material be used?

- Can continue to be used to do geotextile, but because the geotextile after the strength of the fiber is affected, can only be crushed after the geotextile for the production of low grade geotextile, for example, the national standard geotextile crushed material can generally be used Non-standard geotextile production, but in strict accordance with the proportion of added, should not add too much crushed material.

- Q: Water board and water pipes and quick overburden trees

- Set aside the road to pull the car, little by little to fill the soil, I am specializing in the production of geotextile, drainage board, wish smooth

- Q: How do geotextiles help with filtration in stormwater management?

- Geotextiles help with filtration in stormwater management by acting as a barrier that allows water to pass through while trapping sediment and other pollutants. This helps to prevent the contamination of water bodies and promotes the retention of clean water within the stormwater management system.

- Q: What are the geotextiles for concrete health

- Is non-woven material

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles act as a barrier between the soil and chemicals, preventing their infiltration into the ground. They effectively filter and separate contaminants, allowing water to pass through while trapping the harmful substances. This helps to protect the soil from contamination and maintain its quality for various applications, such as agriculture or construction.

- Q: Are geotextiles resistant to mold and mildew?

- Yes, geotextiles are typically resistant to mold and mildew due to their synthetic materials and non-biodegradable nature.

- Q: Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used in various landscaping applications such as weed control, erosion control, ground stabilization, and separation of different soil layers. Geotextiles help to improve the overall performance and durability of landscaped areas.

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the permeability of the geotextile, the pore size distribution, the thickness and weight of the geotextile, the hydraulic gradient, and the particle size of the soil being filtered.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are often used as a component of erosion control systems to stabilize the soil and prevent erosion. They can be placed in coastal areas to reinforce structures such as revetments, groynes, or breakwaters, helping to reduce wave impact and erosion.

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Used in road, railway tunnel waterproof board behind, wrapped blind pipe, roadbed blind ditch, roadbed filter layer and so on.

Send your message to us

Naue Geotextile PP Plastic Animal Fence from Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords