Aashto M288 Class 1 PP or PET Filament Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PP or PET Woven Geotextile

Woven Geotextile Introduction

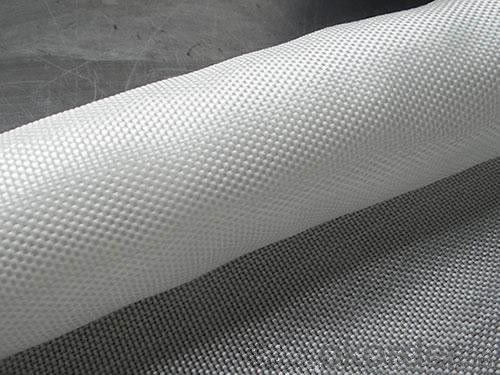

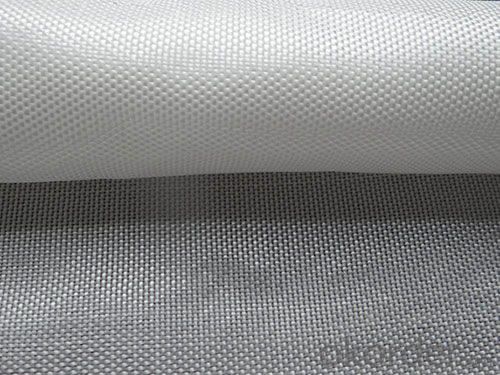

Woven Geotextile is made of high tenacity and high molecular weight polyester or polypropylene yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

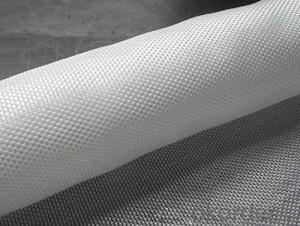

Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing reinforcement, filtration, and separation functions. They help to prevent soil erosion and retain sediment within the geotube, while allowing water to pass through. Additionally, geotextiles enhance the overall stability and durability of geotubes, ensuring their effectiveness in various applications such as coastal protection and dewatering.

- Q: What are the quality control measures for geotextile manufacturing?

- Quality control measures for geotextile manufacturing include conducting regular inspections throughout the production process to ensure that the geotextiles meet specified standards. This involves checking the raw materials used, monitoring the manufacturing equipment for proper functioning, and conducting tests on the finished products to assess their strength, durability, and other performance characteristics. Additionally, quality control measures may involve implementing standard operating procedures, conducting routine quality audits, and adhering to relevant industry and regulatory guidelines.

- Q: Are geotextiles suitable for use in drainage ditches?

- Yes, geotextiles are suitable for use in drainage ditches. Geotextiles can be used as a filtration and separation layer in drainage systems to prevent soil erosion and clogging while allowing water to flow through. They help improve the overall performance and longevity of drainage ditches by enhancing their filtration and drainage capabilities.

- Q: Are geotextiles resistant to UV radiation?

- Yes, geotextiles are typically designed to be resistant to UV radiation. They are often made from materials that have UV stabilizers or are treated with UV-resistant coatings, ensuring their durability and longevity when exposed to sunlight.

- Q: What are the design considerations for geotextile-reinforced soil walls?

- Some of the design considerations for geotextile-reinforced soil walls include the selection of appropriate geotextile material, determining the required strength and stability of the wall, evaluating the site conditions and soil properties, considering the drainage requirements, ensuring proper connection and anchorage of the geotextile to the wall, and considering any potential environmental factors that may affect the performance of the wall.

- Q: How do geotextiles help with reinforcement of geogrids?

- Geotextiles help with the reinforcement of geogrids by providing a stable base and preventing soil erosion. They act as a separation layer between the geogrid and the soil, distributing the load evenly and increasing the overall strength and stability of the structure.

- Q: Can geotextiles be used in bridge abutment reinforcement?

- Yes, geotextiles can be used in bridge abutment reinforcement. Geotextiles are commonly employed in civil engineering projects, including bridge construction, to improve soil stability and provide erosion control. When used in bridge abutment reinforcement, geotextiles can help distribute loads, prevent soil erosion, and increase the overall stability and longevity of the structure.

- Q: Basement roof cover soil thickness and geotextile shop in what position,

- The size of the thickness of the roof cover of the basement garage is in the specification of the air defense design

- Q: How do geotextiles help in preventing the migration of fine particles in soils?

- Geotextiles help in preventing the migration of fine particles in soils by acting as a barrier or filter that allows water to pass through while retaining the particles. This prevents the particles from being eroded or washed away by water flow, thereby stabilizing the soil and reducing the risk of erosion.

- Q: How do geotextiles help with pavement maintenance?

- Geotextiles help with pavement maintenance by acting as a barrier between the subgrade soil and the pavement layers, preventing the mixing and migration of soil particles. This helps to maintain the structural integrity of the pavement, reducing the chances of cracks, potholes, and other damages caused by the movement of underlying soil. Additionally, geotextiles can improve drainage and filtration, reducing the risk of water accumulation beneath the pavement and extending its lifespan.

Send your message to us

Aashto M288 Class 1 PP or PET Filament Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords