Geogrids Noise Reduction PP Biaxial Geogrid / Fiberglass / Polyester Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

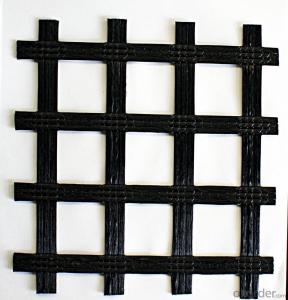

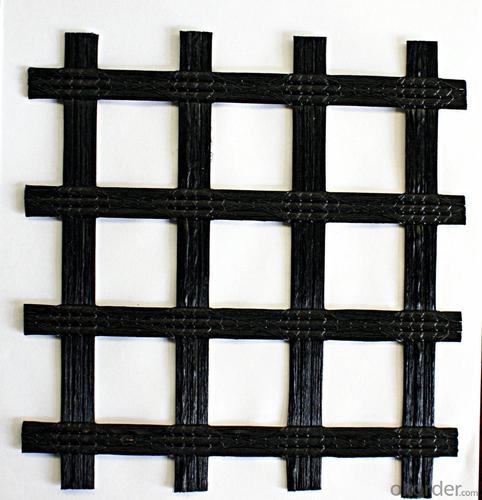

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

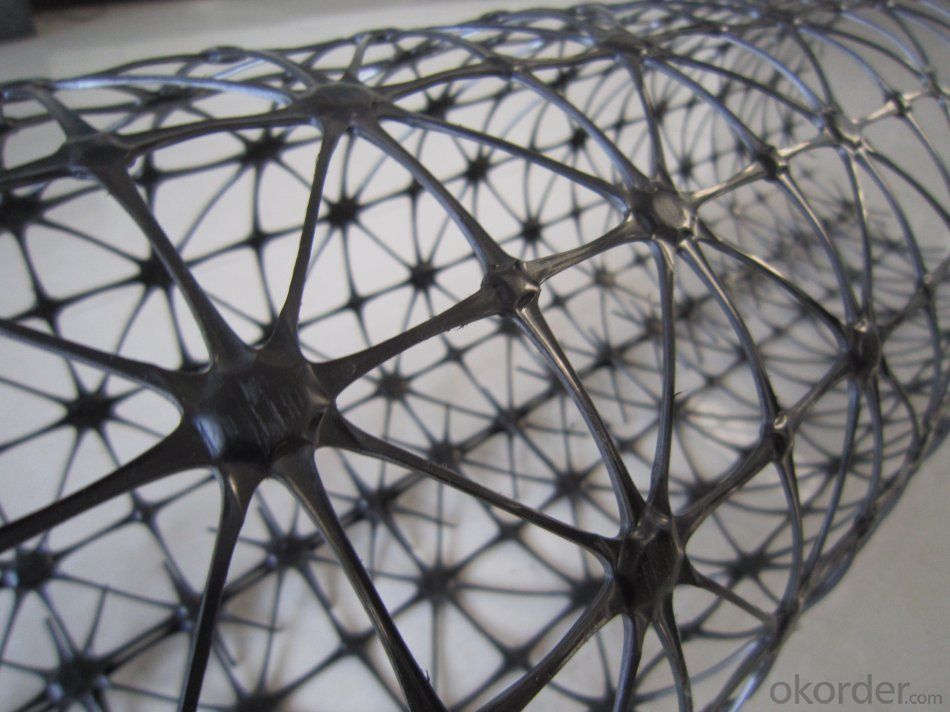

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they enhance the stability and strength of the soil by distributing loads and reinforcing the ground. This helps in the construction of structures on weak or unstable soil conditions. Secondly, geogrids improve the longevity of infrastructure by reducing soil erosion and preventing soil settlement. They also provide better load distribution, reducing the need for excessive excavation and backfilling. Additionally, geogrids are cost-effective as they require less material and labor compared to traditional construction methods. Overall, using geogrids in construction projects can result in improved structural integrity, increased durability, and cost savings.

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving individual yarns together, creating a grid-like structure. Non-woven geogrids, on the other hand, are manufactured by bonding or interlocking fibers together through mechanical, thermal, or chemical processes. The key difference is in the manufacturing process, which results in woven geogrids being stronger and more rigid, while non-woven geogrids tend to be more flexible and have higher tensile strength. Additionally, woven geogrids are generally used in applications that require high load-bearing capacity, while non-woven geogrids are often used for soil stabilization and separation purposes.

- Q: EG90R what is the geogrid material?

- One way pull plastic geogrid, also called one-way plastic geogrid

- Q: Can geogrids be used in reinforced soil slopes for seismic applications?

- Yes, geogrids can be used in reinforced soil slopes for seismic applications. Geogrids are commonly used as reinforcement elements in soil structures to improve their stability and resistance to seismic forces. They provide additional tensile strength, prevent soil movement, and enhance the overall performance of the slope during seismic events.

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional tensile strength and stability. These materials enhance the load-bearing capacity of the soil, prevent movement and settlement, and distribute the applied loads more evenly. Geogrids also minimize the potential for soil erosion and improve the overall durability and longevity of the reinforced structure.

- Q: Can geogrids be used in temporary construction applications?

- Yes, geogrids can be used in temporary construction applications. Geogrids are commonly used to reinforce soil and provide stability, making them suitable for temporary structures such as retaining walls, roadways, and excavation support. They can be easily installed and removed as needed, making them an effective solution for temporary construction projects.

- Q: Glass fiber grating with large pulling force for Expressway

- To improve the overall use of polyester geogrid using high strength nylon fiber filament, warp knitting mesh fabric.

- Q: How many inspection batches of Geogrid

- 2, steel plastic geogrid: material approach requires the factory certificate and the manufacturer's test report, the test batch of 10 thousand square meters for the base test 1 times.3, glass fiber geogrid: according to the "glass fiber geogrid" GB/T 21825-2008 provisions: the same specifications, the same grade, the same production process, a certain number of stable continuous production (volume 500 or less) per unit product for a batch of inspection.4, polyester warp knitted polyester geogrid: reference plastic geogrid inspection batch.

- Q: How do geogrids improve soil stabilization?

- Geogrids improve soil stabilization by providing reinforcement to the soil. They are designed to distribute and transfer loads across a wider area, reducing the stress on the soil. This helps to prevent soil erosion, improve slope stability, and enhance overall soil performance. Geogrids also increase the shear strength of the soil, allowing it to withstand higher loads and resist deformation.

- Q: Which is the high price of steel plastic geogrid and fiberglass geogrid

- If you take the worst plastic steel and the best glass fiber ratio, the latter price is high

Send your message to us

Geogrids Noise Reduction PP Biaxial Geogrid / Fiberglass / Polyester Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords