Powder Coating Machine for protection of can

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

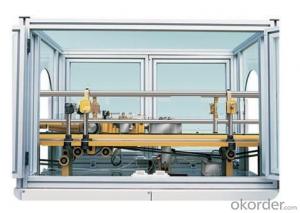

Description of Powder coating machine:

This Powder Coating Machine uses the static to spray the plastic powder onto the welding seam of can body, then use the heat to melt the powder to form a anti-corrosive film to cover the welding line to protect the welding line from being corroded. THis machine adopt the advanced PLC and pneumatic components to make the powder to be absorbed and adhered onto the welding line surface more reliably and steadily, and keep higher utilizing rate of the powder, it is the ideal equipment for can welding line coating and coverage.It can be combined with any type of welding machines to form a Fully Automatic Can Production Line.

Main Feature:

1. The Powder Coating Machine can be combined with any type of welding machines to form a Automatic Can Production Line.

2. The Powder supply can be controlled automatically, the machine will alarm and stop automatically when powder use up.

3. Powder is available to be vacuum callback and recycled.

4. The highly auti-abraded and anti-static quality material is adopted to the machine, and the static pressure can be controlled automatically.

Technical Paremeter:

| Transfer speed | 10-70m/min. |

| Production capacity | 600can/min. |

| Coating width | 8-12mm |

| Applicable can diameter | 52-280mm |

| Powder material | Polyester,Epoxies |

| Comperessed air | 0.4mpa,0.5m3/min.,relative temperature<60% |

| Input power | AC220V,50HZ, single phase |

| Power | 2.5KW |

- Q: The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

Send your message to us

Powder Coating Machine for protection of can

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords