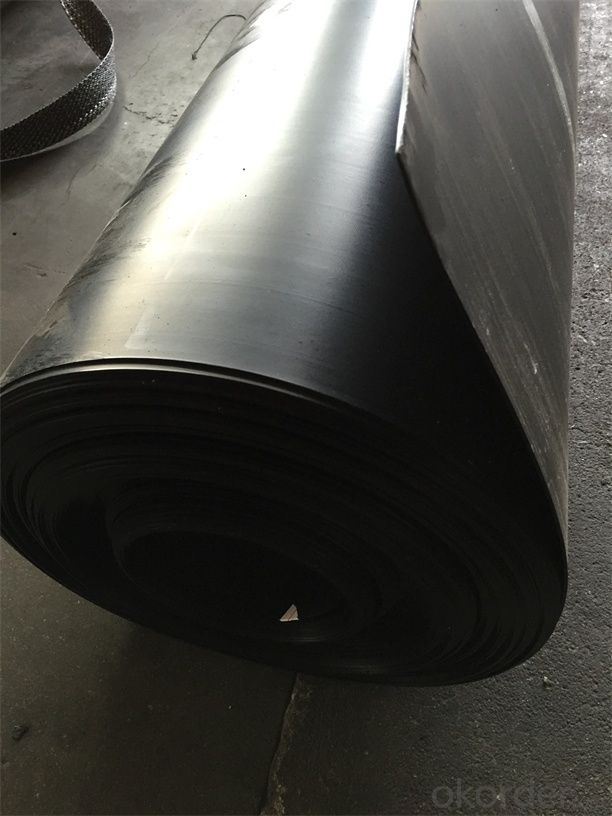

Geotextile Ace Polyvinyl Chloride (PVC) Geomembranes for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Usage :

1.Prevent leakage disposal in waste burying filed or waste burying filed or waste water or waste dregs disposing filed .

2.River bank ,lake dam,mine remaining, reservoir ,tunnel,liquid storage pool (pit ,mine)

3.Preventing leakage in roadbed and other ground-sill .

4.The plane direction laying off of da ,the vertical direction laying for ground-sill,used in the construction fence and waste material filed .

5.Used in seawater or freshwater feel field .

6.Used in ground-sill of rad ,highway,railway and waterproof layer of swelling clay and wet collapsed loss .

7.Preventing leak on rooftop

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer numerous benefits in construction projects. Firstly, they provide effective soil stabilization by preventing erosion, reducing sedimentation, and enhancing soil strength. Secondly, they act as a barrier against weed growth, enhancing the aesthetics and longevity of the project. Additionally, geotextiles facilitate efficient drainage, preventing water accumulation and potential damage to structures. They also aid in separation and filtration, preventing the mixing of different materials and promoting the flow of water. Furthermore, geotextiles are cost-effective and easy to install, saving both time and labor. Overall, the use of geotextiles in construction projects improves durability, reduces maintenance needs, and ensures long-term sustainability.

- Q: How do geotextiles help with separation of different soil layers?

- Geotextiles help with the separation of different soil layers by acting as a barrier or filter between them. They prevent the mixing of different soil types, preventing the migration of fines or small particles from one layer to another. This separation ensures the integrity and stability of each soil layer, allowing for better drainage and preventing the loss of structural properties.

- Q: Can geotextiles be used in tunnel construction?

- Yes, geotextiles can be used in tunnel construction. Geotextiles are often employed as a reinforcement material to enhance the stability and strength of the tunnel lining. They can also be used as a separation layer between the tunnel lining and the surrounding soil, preventing the mixing of different materials and ensuring the overall integrity of the tunnel structure. Additionally, geotextiles can provide filtration and drainage functions, helping to control water flow and mitigate potential issues such as soil erosion or groundwater seepage. Overall, geotextiles play a crucial role in tunnel construction by improving the performance and durability of the tunnel infrastructure.

- Q: How can we file in the Water Resources Department? I was doing hydraulic works with geotextiles, geogrids, gabion, gabbin.

- Water geotechnical engineering geotextile, geogrid, gabion, Geben network should belong to the geotextile material series, you can refer to the required record of the Department of Water Resources on the geotechnical industry for the record requirements. At present, the provinces and cities of the record requirements are not the same, you want to record in which provinces and cities will go to the provincial and municipal water conservancy department official website to see the specific requirements, the Internet will generally have publicity, you can call the consultation. The general information required for the record includes: business license, tax registration certificate, organization code certificate, national industrial production license, safety production license, ISO9000 / ISO certification, legal personality certificate, power of attorney, contract copy in recent years Three-year financial audit report, the company's basic household certification.

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: How do geotextiles help in the separation of materials?

- Geotextiles help in the separation of materials by creating a barrier between different layers of soil or aggregates. They prevent the mixing and migration of materials, such as preventing the intermixing of fine and coarse particles, thereby maintaining the integrity and stability of the construction or landscaping project.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- The guidelines for geotextile installation in erosion control projects may vary depending on the specific project and site conditions. However, some common guidelines include conducting a thorough site assessment, properly preparing the subgrade, ensuring proper overlap and seam strength of geotextile materials, adequately anchoring the geotextile to prevent movement, and regularly inspecting and maintaining the geotextile for any damages or clogging. Additionally, following manufacturer recommendations and consulting with experienced professionals can also provide valuable insights for successful geotextile installation in erosion control projects.

- Q: Can geotextiles be used in green roof drainage systems?

- Yes, geotextiles can be used in green roof drainage systems. Geotextiles, which are permeable fabrics, can be placed within the drainage layer of a green roof system to enhance water flow and filtration. They help to prevent clogging and ensure efficient drainage, promoting healthier plant growth and preventing water accumulation on the roof.

- Q: What are the applications of geotextiles?

- Geotextiles have a wide range of applications in civil engineering and environmental projects. They are commonly used in road construction, where they provide stability, erosion control, and reinforcement. Geotextiles are also utilized in landfills to separate and protect soil layers, preventing contamination. Additionally, they are employed in coastal engineering to mitigate erosion and stabilize shorelines. Geotextiles are also used in drainage systems, agriculture, and landscaping to control erosion, filter water, and promote vegetation growth.

- Q: What are the standards and regulations governing geotextiles?

- The standards and regulations governing geotextiles depend on the country or region. In general, geotextiles are regulated by organizations such as ASTM International and ISO (International Organization for Standardization). These standards typically cover testing methods, specifications for materials and products, installation guidelines, and performance criteria for various geotextile applications. Additionally, specific industries or sectors, like civil engineering or construction, may have their own regulations or guidelines for the use of geotextiles.

Send your message to us

Geotextile Ace Polyvinyl Chloride (PVC) Geomembranes for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords