Polymer cable tray Trough type cable tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

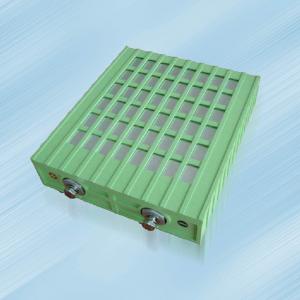

Product Name:

Polymer Trough type cable tray

Introduction:

Polymer cable tray is a tray product of new materials. It is suitable for petroleum, chemical industry, textile, electric power, machinery, transportation, civil construction and other fields. It can replace the traditional metal bridge at present and is the cable bridge for future engineering applications.

Material feature:

1.Polymer cable tray is made of high new polymer material PVC and ABS polystyrene oxygen and other materials. It has the advantages of strong heat resistance, low thermal expansion coefficient, good flame retardant, high insulation performance, strong corrosion resistance, long service life and so on. Compared with traditional products, it has great advantages.

2. The optimized design of the structure improves the flexibility and speediness of the installation of the cable tray. The traditional cable tray structure is complex and requires many parts, while the new alloy plastic cable tray can greatly meet the needs of customers by using only dozens of parts, which greatly improves the flexibility and speed of cable tray installation.

3. Improve the utilization rate of polymer materials, through verification than the conventional increase of about 5%. Polystyrene oxygen has outstanding mechanical properties, especially tensile strength, impact strength, corrosion resistance and creep resistance. Under 21Mpa load for 3000h, the creep value is 0.75%, while PC is 1%, POM is 2.3% and ABS is 3%. Through the full mixing with PVC, improve the utilization rate, more than 5% higher than conventional.

4. The product has good appearance design and high decoration. And the product is made of plastic material, by injection molding and extrusion molding, has a good appearance design, through structural optimization design, so that it can be arbitrary combination, decorative strong, overcome the traditional products poor appearance, low decorative performance shortcomings.

5. High polymer cable tray has long service life. Compared with the traditional steel cable tray, the service life is 5-8 times longer, which reduces the secondary input cost of replacing the cable tray. The corrosion resistance of traditional steel cable tray products is poor, and the cable tray must be coated and repaired regularly. The cost of materials and labor is high, and the corrosion resistance of polymer tray is strong, which greatly reduces the maintenance cost and maintenance time. Alloy plastic cable tray does not need power outage during maintenance, and the loss caused by production suspension is correspondingly reduced, which effectively improves the production efficiency.

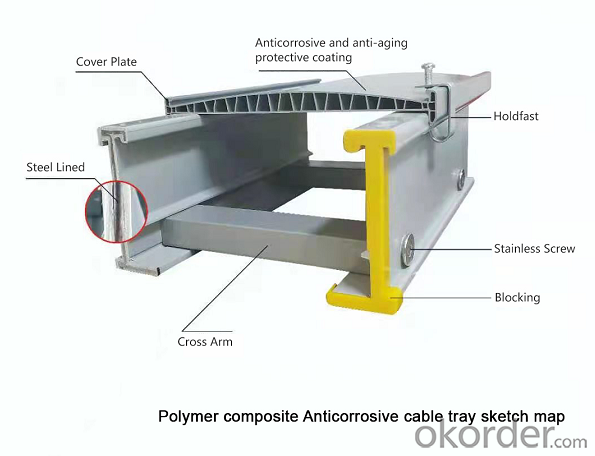

Parts:

Cover Plate、Steel Lined、 Cross Arm、Blocking 、Stainless screw、Holdfast、Anticorrosive and anti-aging protective coating

Process:

Built in steel plate extrusion molding .All parts can be galvanized

Application:

It is suitable for petrochemical factory、chemical plants with high salinity、Bridges, tunnels, hotels, etc. It is suitable for power cables below 10K.

- Q: Such as: 200 * 100 * 1.5. Ordinary, galvanized and hot galvanized. How is the price calculated? Is there a formula? More

- The problem is too big, find a factory to set the information bar

- Q: What are the specifications for cable tray installation? What should I pay attention to when installing?

- Copper core XLPE insulated PVC sheathed flame retardant power cable, 5x6mm2

- Q: Electrical engineering bridge; two sets of cable bridge in the same height parallel laying, during which the net distance should be at least the number of centimeters. Thank you hurry

- Please refer to GB electrical installation installation cable construction and acceptance specifications 5.3 cable duct laying 5.3.1 in the following locations, the cable should have a certain mechanical strength of the protective tube or the installation of protective cover: 1 cable into the buildings, tunnels, Through the floor and the walls. 2 from the channel lead to the poles, equipment, wall surface or house pedestrians easy to close, from the ground height of 2m below a section. 3 may have a gear that has been above the cable section; 4 other places that may be subject to mechanical damage. 5.3.2 There should be no water inside the pipeline and no clogging. When wearing the cable, do not damage the protective layer, can be used non-corrosive lubricant (powder). 5.3.3 cable laying in the laying of cables, should be clear, remove debris. 5.3.4 The number of cables in the pipe should meet the design requirements; AC single-core cable shall not penetrate the steel pipe alone. 5.3 Laying of cables in cable ducts 5.3.1 In the following locations, the cable shall have a protective tube of mechanical strength or a protective cover: 1 cable into the building, tunnel, through the floor and the wall. 2 from the channel lead to the poles, equipment, wall surface or house pedestrians easy to close, from the ground height of 2m below a section. 3 may have a gear that has been above the cable section; 4 other places that may be subject to mechanical damage. 5.3.2 There should be no water inside the pipeline and no clogging. When wearing the cable, do not damage the protective layer, can be used non-corrosive lubricant (powder). 5.3.3 cable laying in the laying of cables, should be clear, remove debris. 5.3.4 The number of cables in the pipe should meet the design requirements; AC single-core cable shall not penetrate the steel pipe alone.

- Q: Cable tray 300 * 100 according to the specification can accommodate how many cables

- Coaxial cable Fine cable laying should not be twisted; b. The radius of the cable should be greater than 20cm; c. Installed in the cable on the work of the distance between the work sites should be greater than 05 meters; d. The installation of the cable connector should be reliable, and should prevent the signal from short circuit; Fine cable alignment should be in the cable slot to prevent damage to the cable; f. When laying the cable, do not pull hard to prevent the pull off; A section of the cable should be less than 183 meters, 183 meters within the two sections of cable can generally be used "T" head lengthened; h. Both ends must be installed terminal device, each at least one terminal to ground; i. Coaxial cable can not be installed in the outdoor, installed in the outdoor part of the casing should be installed. Twisted pair Twisted pair in the corridor and indoor alignment should be in the cable slot, should be straight alignment; b. Workstation to hub twisted pair of the longest distance of 100 meters, more than 100 meters available twisted pair connector to lengthen; c. Twisted wire in the machine room to be bundled into the line line, the alignment must have some rules, not chaos; d. Twisted pair at both ends to indicate the number, easy to understand the node and Hub interface corresponding relationship; e. Twisted pair should be firmly inserted into the hub and workstation network card; f. When the node is not used, do not unplug the twisted pair, it does not affect other nodes work; Twisted pair is generally not installed in the outdoors, a small part of the installation in the outdoors, installed in the outdoor part of the casing should be installed; h. Use eight core twisted pair, install their own joints, the eight lines should be installed, do not just install four lines, cut the other four lines.

- Q: Steel cable bridge installation, how far a boom

- Usually 1.5-1.8 m, depends on the load, the larger the bridge is the best distance of 1.5 meters

- Q: Do not use fire blocking material? Question added: commonly used models of fire pack specifications which ah more

- First to figure out what the three lines are, if I guess good, it should be a FireWire, a zero line, a switch line. (But how is there no ground?) Come on according to this then L connected to the line of fire, N then zero line, there is a sign of the ground wire. Do not know their own words, do not mess up, called an electrician to pick up better, or easy to accident Oh!

- Q: What is a cable tray? What is the purpose of the cable tray?

- Power Cable External Metal Armor Grounding is to avoid the occurrence of zero sequence current when the housing is live (this can not be used with a single core metal case cable is a reason).

- Q: What is the difference between a trough bridge and a tray tray?

- The steel pipe is easy to make the cable broken, and the steel is conductive. Really want to break the skin, increase the danger

- Q: To ask the gods, with cad cable tray design, how to take into account the layers? Is a layer of a painting or a few layers together, how to set the specific color

- . the bridge connecting piece, is in the direction of the extension of the bridge to connect the adjacent two sections of the bridge connection device, connecting pieces and the bridge has a fixed bolt with the prefabricated hole (or groove); . A component of a hanger. When the bridge is hoisted, the hoisting bracket is generally used. The lifting bracket is composed of a boom and a crossbar, and the upper end of the boom is fixed on the support of the roof panel, and the lower end is mounted for the weight of the bridge The

- Q: Do not have a very professional, can mark the specific layout, specifications can be

- Transfer test Note: in the high-pressure test equipment and high voltage around the lead, should be installed to block and hang warning signs When conducting a high voltage test, the operator and the high voltage circuit should have sufficient safety distance after the end of the high-pressure test, the DC test equipment and large capacitance of the equipment to be tested multiple discharge, discharge time of at least 1min or more Where the absorption ratio of less than 12 of the motor, should first dry and then exchange pressure test circuit breaker AC voltage test should be in the sub-closing state were carried out separately In addition to the complete installation of the factory, the insulation equipment should be separated from each other to do DC voltage, the test voltage 05 times the rated voltage per stage increased in stages, each phase to stay 1min, and record the leakage current

Send your message to us

Polymer cable tray Trough type cable tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords