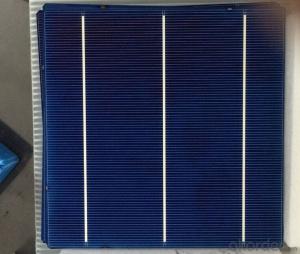

High Quality Floating Polycrystalline Solar Cells 17.00-17.19effy

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Cells:

solar cells, when struck by photons of light from the sun, generates an electrical current which can then be used to power DC or AC electrical loads.

A solar cell is made of silicon. Computer chips are made of this same material. Basically, when light strikes the surface of a solar cell some of it is absorbed into the silicon. This light energy bumps the electrons loose and causes energy to flow

Solar cells is made by solar wafer, it has three categories of solar cell right now, monocrystalline polycrystalline and thin film,These cells are entirely based around the concept of PN junction, which is the critical part of solar module, it is the part that can convert the light energy into electricity, the thickness is from 180um to 200um, with even busbars to conduct electricity, textured cell can decrease diffuse reflection; they are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current;With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Specifications

Efficiency Code | 170 | 168 | 166 | 164 | 162 | 160 | 158 | 156 |

Efficiency Eff(%) | 17.00-17.19 | 16.80-16.99 | 16.60-16.79 | 16.40-16.39 | 16.20-16.39 | 16.00-16.19 | 15.80-15.99 | 15.60-15.79 |

Power Ppm(w) | 4.14-4.19 | 4.09-4.14 | 4.04-4.09 | 3.99-4.04 | 3.94-3.99 | 3.89-3.94 | 3.85-3.89 | 3.80-3.85 |

Max.Power current Ipm(A) | 7.97 | 7.91 | 7.82 | 7.77 | 7.72 | 7.67 | 7.62 | 7.56 |

Min.Power Current Ipm(A) | 7.73 | 7.68 | 7.58 | 7.54 | 7.49 | 7.44 | 7.39 | 7.34 |

Short Circuit Current Isc(A) | 8.45 | 8.40 | 8.34 | 8.30 | 8.25 | 8.21 | 8.15 | 8.10 |

Max Power Voltage Vpm(V) | 0.522 | 0.520 | 0.519 | 0.516 | 0.513 | 0.511 | 0.508 | 0.505 |

Open Circuit Voltage Voc(V) | 0.624 | 0.622 | 0.620 | 0.618 | 0.616 | 0.614 | 0.612 | 0.609 |

Solar Cells Advantage:

• High efficiency and stable performance in photovoltaic conversion.

• Advanced diffusion technique ensuring the homogeneity of energy conversion efficiency of the cell.

• Advanced PECVD film forming, providing a dark blue silicon nitride anti-reflection film of homogenous color and attractive appearance.

• High quality metal paste for back surface and electrode, ensuring good conductivity, high pulling strength and ease of soldering.

• High precision patterning using screen printing, ensuring accurate busbar location for ease with automatic soldering a laser cutting.

Features:

High efficiencies up to 16.4%

Proven long term mechanical stability of silicone

Make of highly purified poly silicone

Three bus bars for reduced series resistance and improved module and cell efficiency

Blue anti-reflecting coating ensures improved light absorption and increased efficiency

Acid texturization offers a uniform appearance and virtually invisible crystal structure

Excellent low light behavior for improved energy yield

FAQ

We have organized several common questions for our clients,may help you sincerely:

①What price for each watt?

It depends on the efficiency of the solar cell, quantity, delivery date and payment terms.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③Can you provide the peripheral products of the solar panels, such as the battery, controller, and inverter? If so, can you tell me how do they match each other?

Yes, we can, we have two companies for solar region, one is CNBM International, the other is CNBM engineering Co.

We can provide you not only the solar module but also the off grid solar system, we can also provide you service with on grid plant.

④What is your warranty of solar cell?

Our product can promise lower than 0.3% open box crack, we support claim after opening the box if it has crackm color difference or sth, the buyer should give pictures immediately, we can not accept the claim after the solar cell has assembled to solar panel.

• Timeliness of delivery

• ⑤How do you pack your products?

We have rich experience on how to pack the solar cell to make sure the safety on shipment, we could use wooden box or pallet as buyer's preference.

How Monocrystalline Cells Are Made

As the name implies this type of solar panel are unique in their use of a single, very pure crystal of silicon. Using a process, similar to making semi-conductors, the silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace. Heat is then applied and the result is carbon dioxide and molten silicon. This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industry, which requires a much higher purity level.

This is accomplished by passing a rod of impure silicon through a heated zone several times in the same direction. This procedure "drags" the impurities toward one end with each pass. At a specific point, the silicon is deemed pure, and the impure end is removed.

Next, a silicon seed crystal is put into a Czochralski growth apparatus, where it is dipped into melted polycrystalline silicon. The traditional way of adding boron, is to introduce a small amount of boron during the Czochralski process. The seed crystal rotates as it is withdrawn, forming a cylindrical ingot of very pure silicon.

Wafers are then sliced out of the ingot, then sealed back to back and placed in a furnace to be heated to slightly below the melting point of silicon (1,410 degrees Celsius) in the presence of phosphorous gas. The phosphorous atoms "burrow" into the silicon, which is more porous because it is close to becoming a liquid. The temperature and time given to the process is carefully controlled to ensure a uniform junction of proper depth.

- Q: What is the role of combiners in solar cell systems?

- The role of combiners in solar cell systems is to combine the electrical outputs from multiple solar panels into a single circuit, allowing for more efficient utilization of the generated power.

- Q: Can solar cells be used in emergency lighting?

- Yes, solar cells can be used in emergency lighting. Solar cells convert sunlight into electricity, which can then be stored in batteries for use during emergencies or power outages. This makes solar-powered emergency lighting a reliable and sustainable option.

- Q: Are solar cells durable?

- Yes, solar cells are generally durable. They are designed to withstand various weather conditions, including rain, snow, and extreme temperatures. Additionally, most solar cells come with warranties that guarantee their performance for several decades.

- Q: What is the solar cells market in China?

- Solar cells, is the "ideal" energy of human being's life, solar energy has changed the traditional way of obtaining energy by battery technology. But this technology is limited due to what solar cells needs to work- the weather factors, the solar energy battery can not work properly under rainy or cloudy weather. Therefore, solar cells market is not very well developed in some part of China where there are not much sun.

- Q: What is the typical size and weight of a solar cell?

- The typical size of a solar cell ranges from a few square centimeters to several square meters, while the weight can vary from a few grams to a few kilograms, depending on the technology and application.

- Q: Can solar cells be used to power remote wildlife monitoring systems?

- Yes, solar cells can be used to power remote wildlife monitoring systems. Solar cells convert sunlight into electricity, providing a sustainable and reliable power source for monitoring equipment in remote areas where access to the electrical grid may be limited or unavailable. This allows for continuous operation of the monitoring systems without the need for frequent battery replacements or reliance on fossil fuels.

- Q: Can solar cells be used for powering oil rigs?

- Yes, solar cells can be used for powering oil rigs. They can provide a renewable and sustainable source of energy to run various equipment and systems on the rig. Solar panels can be installed on the rig's surface or nearby structures to capture sunlight and convert it into electricity, reducing the reliance on traditional fossil fuel-based power sources.

- Q: How do solar cells perform in areas with high levels of snowfall?

- Solar cells typically do not perform optimally in areas with high levels of snowfall. The accumulation of snow on the surface of solar panels obstructs sunlight from reaching the cells, reducing their efficiency. However, advancements in technology and the tilt angle of solar panels can help minimize this issue by allowing the snow to slide off more easily. Additionally, regular maintenance practices such as clearing the snow can help ensure better performance during snowy periods.

- Q: How are solar cells installed?

- Solar cells are typically installed on rooftops or in open areas with maximum exposure to sunlight. The installation process involves mounting the solar panels onto a strong structure using racking systems, securing them in place. Electrical wiring is then connected between the panels, and an inverter is installed to convert the captured solar energy into usable electricity. Finally, the system is connected to the electrical grid or batteries, enabling the generated power to be used.

- Q: What is the impact of snowmelt on solar cell efficiency?

- The impact of snowmelt on solar cell efficiency is generally positive. Snowmelt helps to remove any snow cover on solar panels, allowing them to receive more sunlight and generate more electricity. This increased exposure to sunlight improves the efficiency of the solar cells and enhances their performance. Additionally, snowmelt also helps to prevent any potential damage that could occur due to the weight of accumulated snow on the panels.

Send your message to us

High Quality Floating Polycrystalline Solar Cells 17.00-17.19effy

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords