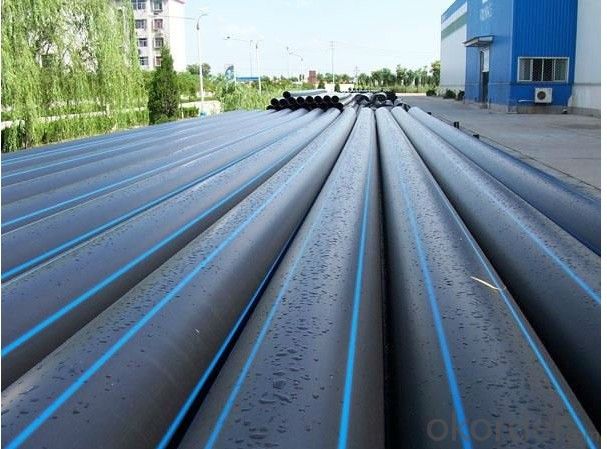

Plastic Pipe--HDPE Water Supply Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of HDPE Water Supply Pipe

Material: PE80/ PE100 (mainly PE 100 now).

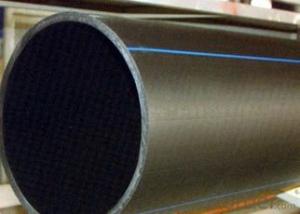

Sizes: 20mm--630mm

SDR: SDR11,SDR13.6,SDR17,SDR21,SDR26,SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

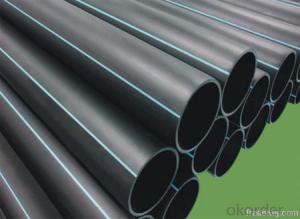

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of HDPE Water Supply Pipe

1.Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2.Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums,

or electron chemical corrosion. except for few strong oxidants

3.High strength, good performance to resist the environmental stress cracking, good creep

resistance.

4.Good flexibility: small diameters PE pipe for water supply can be coiled and supplied for longer

length, which saves a large number of fittings , PE pipe can be easily shifted according to

requirement of the projects.

5.Light weight ,simple safe and reliable welding technique,convenient construction and lower cost

of the whole engineering,

6.Smooth interior wall, small water resistance, high flow capacity,

7.Long service life :up to 50 years under normal conditions.

8.Recyclable, benefit to the environment

- Q: How are steel pipes used in the automotive manufacturing industry?

- Steel pipes are commonly used in the automotive manufacturing industry for various purposes such as exhaust systems, chassis frames, and structural components. These pipes provide durability, strength, and resistance to corrosion, making them ideal for applications that require high performance and reliability.

- Q: What is the maximum diameter of steel pipes?

- The maximum diameter of steel pipes can vary depending on various factors such as manufacturing capabilities, industry standards, and specific project requirements. However, steel pipes can typically range from a few millimeters in diameter for small-scale applications to several meters in diameter for large-scale industrial projects.

- Q: What is the average lifespan of a steel pipe?

- The average lifespan of a steel pipe can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, with proper installation and maintenance, a steel pipe can typically last anywhere from 20 to 100 years.

- Q: How do steel pipes handle chemical exposure?

- Steel pipes are highly resistant to chemical exposure due to their inherent corrosion-resistant properties. The steel used in pipes is often coated with protective layers or made from stainless steel, which makes them capable of withstanding the effects of various chemicals without deteriorating or reacting. This allows steel pipes to handle chemical exposure effectively and maintain their structural integrity over time.

- Q: How long is the seamless tube?

- Generally finished seamless steel tubes are less than twelve meters, mainly for the convenience of shipment.In times of rolling (processing), the steel pipe can reach 80 meters or longer.

- Q: Seamless steel tube 89X4 meters, how heavy?

- Generally seamless steel pipe wall thickness will be uneven, according to the theory, each meter is 8.3844 kilograms, but if the wall thickness is poor 20--30 wire, then the weight will increase some

- Q: Are steel pipes suitable for transporting fluids?

- Yes, steel pipes are suitable for transporting fluids. They have high strength and durability, can withstand high pressure and temperature, and are resistant to corrosion, making them ideal for various fluid transportation applications such as oil, gas, water, and sewage.

- Q: How are steel pipes used in the manufacturing of hydraulic systems?

- Steel pipes are commonly used in the manufacturing of hydraulic systems due to their durability, strength, and resistance to high pressures. These pipes are typically used to transport hydraulic fluid, providing a reliable and leak-free connection between various components such as pumps, valves, and actuators. Steel pipes also offer the advantage of being able to withstand harsh operating conditions and ensure efficient fluid flow, making them an essential component in hydraulic system manufacturing.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are commonly used in the mining industry for various purposes such as transporting minerals, water, and gases underground, as well as for constructing mine shafts, tunnels, and mine infrastructure due to their durability, strength, and resistance to corrosion.

- Q: What are the common factors affecting the lifespan of steel pipes?

- There are several common factors that can affect the lifespan of steel pipes. 1. Corrosion: Corrosion is one of the primary factors that can significantly reduce the lifespan of steel pipes. Exposure to moisture, chemicals, and harsh environmental conditions can cause the steel to rust and deteriorate over time. 2. Quality of materials: The quality of the steel used in manufacturing the pipes plays a crucial role in determining their lifespan. Higher-quality steel with better resistance to corrosion and other forms of degradation will generally have a longer lifespan compared to lower-grade materials. 3. Installation and maintenance practices: Proper installation and regular maintenance are essential for ensuring the longevity of steel pipes. Improper installation techniques, such as inadequate support or improper alignment, can lead to premature failure. Similarly, neglecting routine maintenance, such as cleaning and inspection, can accelerate the degradation process. 4. Operating conditions: The operating conditions to which steel pipes are exposed can also impact their lifespan. Factors such as temperature, pressure, and the type of fluid or gas being transported can all affect the integrity of the pipes. Extreme conditions, such as high temperatures or corrosive substances, can significantly reduce the lifespan of steel pipes. 5. Mechanical stress: Excessive mechanical stress, such as vibration, impact, or heavy loads, can weaken steel pipes over time. This stress can lead to cracking, deformation, or even complete failure if not properly managed or accounted for during the design and installation process. 6. Environmental factors: The surrounding environment can have a significant impact on the lifespan of steel pipes. Exposure to harsh weather conditions, such as extreme temperature variations or frequent freeze-thaw cycles, can accelerate the deterioration process. Additionally, the presence of pollutants or aggressive substances in the surrounding soil or water can also contribute to the degradation of steel pipes. In summary, the lifespan of steel pipes can be affected by factors such as corrosion, material quality, installation and maintenance practices, operating conditions, mechanical stress, and environmental factors. By considering and addressing these factors, it is possible to extend the lifespan of steel pipes and ensure their durability and reliability.

Send your message to us

Plastic Pipe--HDPE Water Supply Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords