PLASTIC GRANULE CUTTER FPB-200 applicable to composite plastic brace cutting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Application: plastic pelletize

Place of Origin: Zhejiang, China (Mainland)

Brand Name: GT

Model Number: <SPAN class=attr-value title=FPB-140/150/180/200>FPB-140/150/180/200

Saw Blade Diameter: 2-3mm

Power(W): 3-4kw

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | wooden case |

|---|---|

| Delivery Detail: | 30-45days |

<STYLE type=text/css> .richtext [data-maya] { width: 750px; font-size:14px; }

Specifications

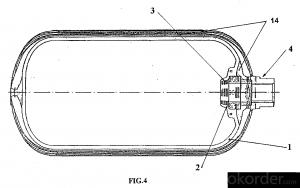

plastic grain cutter

plastic granule cutter

plastic pellet cutter

Product Description

Rolling blade of cutting grain : Φ140mm × Φ140mm,Φ200mm× Φ 200(mm)

Material of rolling blade : Alloy steel.

Max. Prilling capacity : 200-600kg/h

Motor power : 3-4kw

Speed control :electromagnetic

Weight :500kg

- Q: Figure plastic parts, motorcycle, instrument shell, plasticI want to refit the instrument and refit the instrument and meter. The shape of the instrument shell is identical. The space between the instrument shells is too emptyWhich tools cut material thickness about 3mm?Art knife, scissors line, art knife, control power, easy to scratch, scratches, scissors left section is too rough

- Pre painted wire shape curve or sandpaper polished OK wire saw a fileHeating line 3 mm, too thick electric iron difficult to burn, and cut plastic, less electric iron can melt plastic, can remove plastic; two heating edge treatment is not troublesome, only plastic edge heating embrittlement, and even crack melting, slag hanging difficult to smoothAngle grinder into space maneuvers each position angle grinder wrong to manmanmo to prevent brittle plastic heating melting plastic plug wheel

- Q: How do you cut the plastic and use what tool to cut the shape you want?

- The electric heating cut uses the root to be thicker, the spot is fine, the copper wire looks for a root, the soft wooden rod makes the arch copper wire string, looks for two dry batteries to connect the copper wire, two copper wires to scald, the temperature continues enough to add the battery

- Q: What are the requirements for the accuracy of wire cutting plastic die and cold stamping die?

- The plastic mould parts use line cutting relatively less, and the key parts are mostly by grinding and discharging.

- Q: Mainly for length control, plus or minus tolerance should be 0.2The slim saw blade has thickness and is difficult to control

- You can consider a water cut, but it's expensive; it should be up to your requirement.

- Q: Plastic pipe production line cutting process dust?

- Its raw material belongs to petroleum chemical industry. Cutting plastic material will produce a lot of organic waste gas and micro particles, please pay attention to protective measures, minimize contact.

- Q: I bought PVC transparent plastic board, seek expert advice, with what knife good cut

- Woodworking table saw, alloy saw blade, tooth number 80-120

- Q: Plasma cutting function of non metal like plastic

- No! Because plasma cutting and welding principle is the same! Need conductive can cut! Plastic is not conductive to cut! Even if we can not cut plastic cutting! The plasma temperature is high temperature will melt the plastic contact!

- Q: What is the best way to cut POM plastic?

- Band sawing machine processing of POM is generally not heated and melted, speed, high efficiency, and with coolant function (the cooling water pump), hand or electric saw might be added in cooling.

- Q: How is it simple and practical to cut rough plastic pipes?

- Use a carpenter's hand to hold a circular saw. Heating iron plate cutting. Cutting with resistance wire. Use battery heating resistance wire cutting.

- Q: To make a plastic cutting machine. The main is the removal of 2 10CM around the rim. Plastic (PPS material), with what method good., scissors. Laser cutting. After heating the cylinder sealing knife under the action thought. But hope master guiding is not ideal!

- Water jet cutting, because mechanical cutting should take into account the chip, hot cutting and softening

Send your message to us

PLASTIC GRANULE CUTTER FPB-200 applicable to composite plastic brace cutting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords