Plastic Formwork Concrete Formwork Platform Outrigger for Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

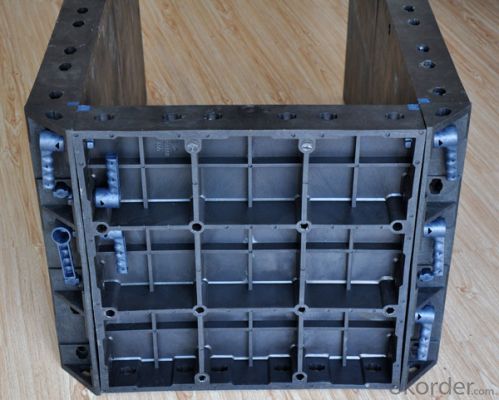

Plastic Formwork Concrete Formwork Platform Outrigger for Scaffolding High Quality

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q: Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Low foaming high strength plastic building template. The template rigid plastic combination, high strength, light weight, impact strength, can be sawable nail can be welded, industrial temperature up to -15 ℃ to 75 ℃ can be applied without cracking. 10 meters high vertical drop does not break, can be used 40 times to 100 times, waste plate can be recycled, more than 30% of the cost savings than the wood template, is the twenty-first century to plastic and wood ideal plastic building template.

Send your message to us

Plastic Formwork Concrete Formwork Platform Outrigger for Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords