Plastic Dimple Drainage Water Treatment Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

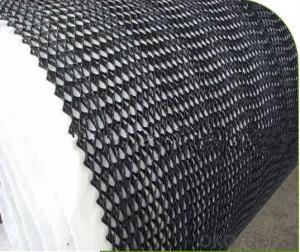

Plastic Dimple Drainage Sheet Introduction

Plastic dimple drainage sheet is made of high molecular, produced by extrusion and adsorption. The tri-diamensional space can drain gas and fluid. It is multi-functional material, can form channels for water and gas easily, which is sound insulation and vibration isolation. In the field of civil construction can be widely used in building roof system layer overhead, planted roof drainage ventilation, basement waterproof system protection, thermal and moisture isolation of the interior surface, road and rail tunnel drainage protection. In the urban land, space, material resources are becoming scare today, plastic dimple drainage sheet to provide the most valuable option.

Plastic Dimple Drainage Sheet Application

Waterproofing system of road

Railway tunnel and underground

Basement of building

Roof garden

Other waterproofing and drainage construction works

Plastic Dimple Drainage Sheet Advantage

-Low cost, High efficiency

-Durable, anti age

-Chemical resistance

-Resistance to puncture of plant roots

-Diverse application

-Simple installation and quality guaranteed

Plastic Dimple Drainage Sheet Specifications

| No. | Item | Technical Index | |||||

| CMAX-H10-1.0 | CMAX-H20-1.0 | CMAX-H10-1.5 | CMAX-H20-1.5 | CMAX-H10-2.0 | CMAX-H20-2.0 | ||

| 1 | Board Thickness, mm | 1.0 | 1.0 | 1.5 | 1.5 | 2.0 | 2.0 |

| 2 | Depth of Dimple, mm | 10 | 20 | 10 | 20 | 10 | 20 |

| 3 | Tensile Strength, N/125px ≥ | 400 | 400 | 500 | 500 | 700 | 700 |

| 4 | Elongation at Break, % | 200 | 200 | 300 | 300 | 400 | 400 |

| 5 | Tensile Strength of Three-dimensional, Kpa | 400 | 320 | 450 | 370 | 500 | 420 |

| 6 | Dimension Stability, % | ±2 | |||||

| 7 | Low Temperature Bending | no creases in low temperature -35℃ | |||||

| 8 | Longitudinal Flow Capacity, cm3/s (water pressure 5KPa) | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

| 9 | Longitudinal Flow Capacity, cm3/s (water pressure 350KPa) | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

Plastic Dimple Drainage Sheet photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. Why choose CNBM?

CNBM is short for China National Building Material Corporation, is a China state owned huge corporation, exported from 1984. CNBM own the largest geosynthetics production base about 667000m2 in China and have about 120production line for all geo materials. For geotextile, we have 38 production lines, our production capacity each day can be 300,000m2.

We passed CE certificate and reaches ASTM standard, have more than 120 customers in EU, USA, Ocean, Africa and all markets. We’ll be your reliable partner in quality and after sales service.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: What are the challenges in installing and maintaining geosynthetic products in earthwork?

- Some challenges in installing and maintaining geosynthetic products in earthwork include ensuring proper placement and alignment of the materials, preventing damage during installation, ensuring adequate compaction and consolidation of the surrounding soil, and addressing issues such as settling, erosion, and shifting over time. Additionally, regular inspections and maintenance are necessary to identify and address any potential issues or damages to the materials, as well as to ensure the long-term effectiveness and performance of the geosynthetic products.

- Q: Can earthwork products be recycled?

- Yes, earthwork products can be recycled.

- Q: Will the mechanical material mechanics and civil material mechanics different?

- Material mechanics is a course, not too much difference in our university material mechanics examination questions are the same as the late course of the different civil class tend to focus on geotechnical mechanics, non-linear analysis of the mechanical class more Concerned structural analysis, elastic mechanics

- Q: How do geogrids aid in stabilization of steep slopes in earthwork applications?

- Geogrids aid in stabilization of steep slopes in earthwork applications by providing reinforcement and preventing soil erosion. They are typically made of high-strength polymer materials that are placed within the soil to create a strong and stable structure. The geogrids interlock with the soil particles, increasing the overall strength and resistance to sliding or slumping. This reinforcement helps to distribute the loads more evenly, reducing the potential for slope failure. Additionally, geogrids help to control soil erosion by providing a barrier that prevents soil particles from being washed away by rainfall or surface water flow. Overall, geogrids improve the stability and longevity of steep slopes in earthwork applications.

- Q: What are the key considerations when using geotextile bags for shoreline restoration?

- When using geotextile bags for shoreline restoration, there are several key considerations to keep in mind. Firstly, the location and condition of the shoreline should be thoroughly assessed to determine if geotextile bags are the appropriate solution. Factors such as wave action, water levels, and soil stability must be evaluated to ensure the bags can withstand the environmental conditions. Secondly, the selection of the right geotextile bag material is crucial. The bags should be made from high-quality, durable materials that are resistant to UV degradation, erosion, and punctures. The bag's permeability should also be considered to allow proper drainage while preventing the loss of fill material. Thirdly, the proper installation technique is essential for effective shoreline restoration. The bags should be placed in a strategic manner, considering factors such as slope stability, water flow patterns, and the desired shoreline shape. Adequate anchoring and secure connections between bags are important to ensure long-term stability and prevent displacement. Additionally, regular monitoring and maintenance of the geotextile bags are necessary. Periodic inspections should be conducted to check for any signs of damage, erosion, or settlement. Timely repairs or adjustments should be made to maintain the integrity of the bags and prevent further shoreline erosion. Overall, careful planning, proper material selection, correct installation, and ongoing maintenance are key considerations when using geotextile bags for shoreline restoration.

- Q: Can geomembranes be used for floating covers in reservoirs?

- Yes, geomembranes can be used for floating covers in reservoirs. Their impermeable nature and resistance to UV rays make them an effective choice for preventing evaporation and contamination of the water in the reservoir. Additionally, the flexibility of geomembranes allows them to conform to the shape of the reservoir and provide a secure cover.

- Q: Can earthwork products be used in retaining wall construction?

- Yes, earthwork products can be used in retaining wall construction. Earthwork products such as geogrids, geotextiles, and erosion control blankets are commonly used to reinforce and stabilize soil in retaining walls. These materials help prevent soil erosion, improve drainage, and increase the overall strength and stability of the retaining wall structure.

- Q: How do earthwork products contribute to erosion control on riverbanks?

- Earthwork products, such as retaining walls and erosion control blankets, play a crucial role in preventing erosion on riverbanks. Retaining walls provide stability and support, preventing soil and sediments from being washed away by the flowing water. They help to redirect the force of the river and reduce the impact of erosion. Erosion control blankets, on the other hand, act as a protective layer, preventing the direct impact of rainfall and runoff on the riverbank soil. These products together help to reinforce the riverbanks, minimize soil erosion, and maintain the ecological balance of the surrounding environment.

- Q: How are gabion baskets used in earthwork applications?

- Gabion baskets are commonly used in earthwork applications as a method of retaining soil and preventing erosion. These wire mesh containers are filled with rocks or other suitable materials and placed strategically to create retaining walls, embankments, or slope stabilization structures. The baskets' flexibility allows them to conform to the terrain and provide a stable and sustainable solution for various earthwork projects.

- Q: How do earthwork products contribute to carbon sequestration?

- Earthwork products, such as biochar and compost, contribute to carbon sequestration by increasing soil organic carbon content. These products have a high carbon content, which when applied to the soil, helps to capture and store carbon dioxide from the atmosphere. Additionally, earthwork products enhance soil fertility and microbial activity, promoting the growth of plants that absorb carbon dioxide through photosynthesis. Overall, the use of earthwork products in agriculture and land management practices can play a crucial role in mitigating climate change by sequestering carbon and reducing greenhouse gas emissions.

Send your message to us

Plastic Dimple Drainage Water Treatment Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords