PF1214 Impact Crusher Machine For Mining

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

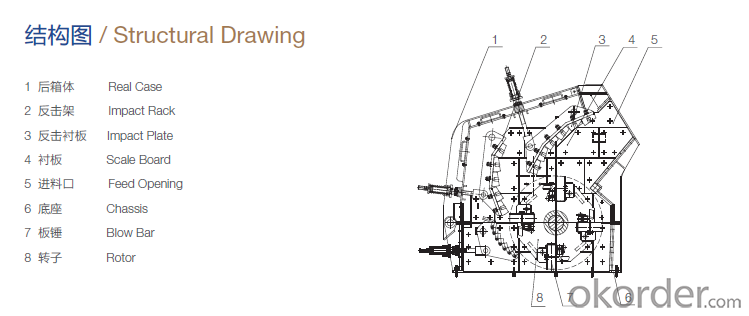

Product Description:

PF1214 Impact Crusher is generally used as secondary crusher, and by changing rotor and crushing cavity, it can also be used as primary crusher according to the customer’s requirements. It is widely used in highway, reservoir, railway, airport and other fields that need rock with cubic shape. It features high capacity, high performance, high reduction ratio, cubic shape and low flakiness.

Product Specifications:

| Model | Spec of Rotor (mm) | Feed Opening Size (mm ) | Max. Feed Edge (mm) | Processing Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimensions (L×W×H) (mm) |

| PF-1007 | φ1000×700 | 400×730 | 300 | 35-50 | 30-55 | 9.45 | 2400×1558×2660 |

| PF-1010 | φ1000×1050 | 400×1080 | 350 | 50-80 | 55-75 | 12.2 | 2400×2250×2660 |

| PF-1210 | φ1250×1050 | 400×1080 | 350 | 80-120 | 110-132 | 14.4 | 2690×2338×2890 |

| PF-1214 | φ1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 16.85 | 2690×2688×2890 |

| PF-1316 | φ1300×1600 | 858×1640 | 350 | 150-220 | 200 | 19.5 | 3096×3273×2667 |

| PF-1010V | φ1000×1050 | 400×1080 | 350 | 55-85 | 55-75 | 13.2 | 2400×2250×2660 |

| PF-1210V | φ1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 15.1 | 2696×2338×2890 |

| PF-1214V | φ1250×1400 | 400×1430 | 350 | 99-160 | 132-160 | 17.85 | 2690×2688×2890 |

| PF-1310V | φ1300×1050 | 490×1170 | 350 | 70-120 | 110-160 | 13.5 | 2780×2478×2855 |

| PF-1315V | φ1320×1500 | 860×1520 | 350 | 150-220 | 180-220 | 20.75 | 3007×2749×2556 |

| PF-1515V | φ1500×1500 | 850×1580 | 350 | 220-280 | 280-315 | 28.5 | 3553×2835×3277 |

| PF-1620 V | φ1640×2000 | 800×2020 | 400 | 400~550 | 250×2 | 39 | 3505×3740×3085 |

FAQ:

Q1: How to confirm that your crushers could be used in our site?

A1: We have been providing crushers for more than ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 15-30 workdays.

Q4: If we can produce some crushers according to customers request?

A4: Yes, we can produce crushers according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Is the city of San Diego using illegals as speed bumps to save money since real speed bumps are so expensive?

- Fairly rotten picture - stating what the first answer said in maybe a slightly clearer way Take the cut or cracked wood and apply tape or equivalent to seal the face of the crack and pour the resin in and let it set, peal off the tape and either provide an insert to take the light bulb or drill a hole afterward to fit it in. In real world, the tape might require backing of some kind, including a poured and set plaster layer to keep the tape from bulging out under the weight and warmth of the setting resin.

- Q: What is a jaw crusher and what is a jaw crusher?.

- Jaw crusher is mainly used as coarse crusher and medium crusher in mines, building materials, infrastructure and other departments. In accordance with the inlet width size is divided into large, medium and small three, the inlet width is greater than 600MM for large machine feeding port width in 300-600MM as midrange computers, the inlet width is less than 300MM for the minicomputer.

- Q: The smoke detector in my bedroom went off at 4 am. I could smell no smoke and a quick check of the house and yard showed nothing out of the ordinary. I was running an oscillating fan at low speed overnight in the bedroom with a window open and the bedroom door open as well. I turned the fan off and the alarm stopped about a minute later. The fan was running normally - no hot smell or excess heat coming from it. The cord and the wall outlet looked fine upon inspection, too. The only theory I have is that the ozone produced by the fan's electric motor somehow triggered the smoke detector. Is this possible? (Also, I noticed that the screen on my televsion which was turned off and about a foot away from the fan was glowing dimly as if receiving a slight charge.)

- Relax , the low battery is probably the cause , change it . I also suggest to be on the safe side have a service guy from your power supplier come and check it out

- Q: i sa it on the home page and i just wanted to know the code so i can have the armor, unless you have to be a member

- Yes okorder

- Q: ok for those who have played it, i'm on castle 17...and i keep failing Dx iv done it at lease 25 times and cant win what am i supposed to do?

- I love this game! 17 took me a while to get through too. I used this walk through to help me. Good luck! :)

- Q: I have been commissioned to create jewelry for a local shop, and one request is for resin pendants. I am looking for some tutorials or guides as to what I will need, what to use as a mold, how to dye and how to add the pendant piece on the top. Any help is greatly appreciated!

- Try looking at it another way. The light levels provided by the sun and moon have been more or less constant throughout the period of time it has taken for us to evolve. So creatures that develop sight with a certain sensitivity that operates well in both light conditions have an advantage over those that do not. That's why the universe seems so adapted to us - because we adapted to it!

- Q: They are ALWAYS in a Tizzy...suppose this Court becomes less Reactionary? if 2 Justices Retire then the Court is More Likely to re-consider Legislation...a con crusher court?

- The People are sending Barry back to Kenya to live with his brother in the mud hut in November !

- Q: DICK, THE BRUISER ! ! ! ! ! ! !

- yea I agree crusher and bruiser were da best but hbk and hulk hogan are pretty close I agree with sutercane jon cena has no moves what so ever

- Q: Deck consists of 40 cardsMonsters (18)1x Plaguespreader Zombie1x Mezuki1x Dark Armed Dragon2x Bone Crusher3x Pyramid Turtle2x Ryu Kokki3x Zombie Master2x Goblin Zombie1x Spirit Reaper1x Ill Blud1x Gorz The Emissary of DarknessSpells (16)1x Card of Safe Return2x Creature Swap3x Zombie World3x Book of Life2x Allure of Darkness1x Giant Trunade1x Mystical Space Typhoon1x Brain Control1x Monster Reborn1x Lightning VortexTraps (6)2x Bottomless Trap Hole2x Dust Tornado1x Torrential Tribute1x Mirror ForceSynchrosGoyo GuardianRevived King Ha DesDoomkaiser DragonBlack Rose DragonDark Strike FighterStardust DragonThought Ruler ArchfiendIron Chain DragonRed Dragon ArchfiendSide Deck1xCard Destruction2x NecrofaceI have placed in the top 4 every weekend at my cities Local tourney since i have made this deck, I have also only been playing Yugioh for about 5-6 months now.

- 8/10 I have a few suggestions I'd run another Il Blud, with one of those in the graveyard drawing a book of life can become a godly turnaround move.........I'd probably take out a goblin zombie for it Solemns are expensive, but if you can get 3 of them I'd take out both dust tornado and throw in all 3 of them You need more tuners.......2 krebons would be a nice fix, you'd have to take out a bone crusher and a goblin zombie and 1 other for them. Add an e teleport to speed up the deck Replace Giant Trunade with heavy storm 3 zombie world is too many......at the very least replace 1 with a terraforming which simply searches out one from your deck for you to help thin out the deck a bit and lastly, Caius the Shadow Monarch works well in this deck.......all the special summoning its not hard to summon him, and he can clear a backrow or a monster so he works well. But zombie world nullifies him........so thats just a suggestion if you don't run so many zombie worlds

- Q: What is the working principle of the counter crusher?

- The working principle of counter impact crusher:The stone fell into the high-speed rotating wheel directly from the upper part of the machine; at high speed under the action of centrifugal force, and another part by way of diversion in the turntable umbrella flying around the stone to produce high speed impact and high density of crushed stone in the fight against each other, will form a vortex motion between the turntable and the chassis caused by repeatedly hit each other, friction, crushing, direct discharge from the bottom. The formation of closed-circuit multiple cycles, controlled by screening equipment to achieve the required particle size.

Send your message to us

PF1214 Impact Crusher Machine For Mining

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords