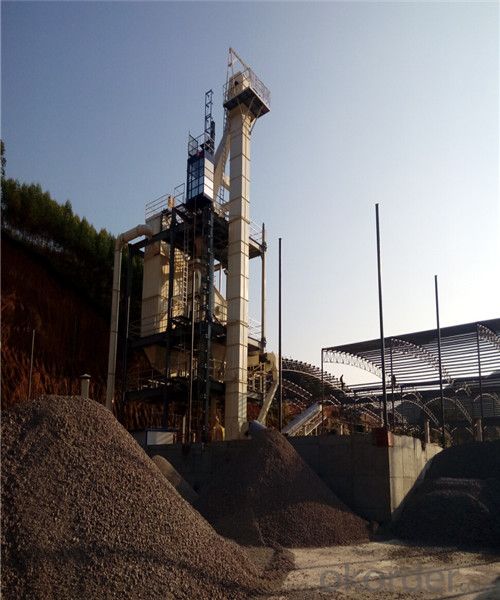

0-4.75mm Dry Sand Making System without any Powder in Site

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dry Method Sand Making System introduction

Dry Method Sand Making System is researched and designed by the senior engineer of CNBM with 10 years experience , it combined all the machine into one equipment, including sand making , separating , dust separation and collection etc for crushing ,grinding ,stone-breaking-stone and reduce the motor power for the main machine .The final products is with stable gradation, cubic shape, adjustable fineness modulus . We control the stone powder content to meet National Standard effectively with Stone-Powder Separation Patent Technology . The final products from our Dry Method Sand Making System meet the requirement for high characteristic concrete and dry-mixed mortar . It saves much cost because the comprehensive performance of the final products is better than river sand and mountain sand . It leave out the heating procedure and save cost with the improved durability and strength and other performance for concrete . The final sand can be used directly without water washing . It is the first choice equipment for sand making in quarry , concrete industry, dry-mixed mortar industry without mixing river sand to adjust the ratio .

Dry Method Sand Making System Advantage :

1. The sand mould is premium.

During production process, “pounding, milling and rock hit rock” are all in one. Finished sands are gradating stability and in good shape (containing 10% or less micro-grading flour). All the sands are almost no flakiness. The finished sands are with more angular, nearly circular, fineness modulus (2.3 ~ 3.0). The percentage of powder content (below 10%) is adjustable. All the performance indicators are meets the national “Architecture Sand” standard GB14684-2011.(patented equipment).

2. Low energy consumption.

The energy consumption is 3kW/t which save 60% energy than the similar international or domestic products, greatly reducing the cost of production. Suit for the concrete sand cause its disposable sand ratio reach 0~4.75mm (>70%). And suit for dry-mixed mortar cause its disposable sand ratio reach 0 ~ 2mm(>40%).

3. Feed size range.

Feeding size from 0mm ~ 120mm.

4. Low noise.

Lower than traditional sand system 20db.

5. Wide range crushing.

In addition to variety of limestone, it can be used for crushing tailings, cobblestone, construction waste and other materials.

6. Environmental Friendly.

The system is equipped with advanced dust removal program, the working environment will be without any dust pollution.

7. Compact Structure.

100 ~ 200m2 (Transporting in parts available, finishing the installation and commissioning in a week normally), low height, the maximum height is 10 ~ 20 m.

8. High degree of automation.

Saving human resources greatly, because the control system is integrated in an operating room.

Dry Method Sand Making System parameter:

SJ-100 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~80mm | 120t | 0~4.75mm(>70%) | 150kW | |

Feeding system | 0~30~80mm | 120t | 20kW | ||

Discharge system | 0~3mm(product) | 80t | 0~2mm(>40%) | 15kW | |

De-dusting system | 15000m3/h(wind) | Powder quantity adjustable | Fine powder | 25kW | |

Sieving system | 0~30mm | 120t | 120t | 0~3mm;3~4.75mm;>4.75mm | 11kW |

Others | 15kW | ||||

Total power | 236kW | ||||

SJ-150 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~100mm | 160t | 0~4.75mm(>70%) | 220kW | |

Feeding system | 0~30~100mm | 160t | 45kW | ||

Discharge system | 0~3mm(product) | 110t | 0~2mm(>40%) | 30kW | |

De-dusting system | 20000m3/h(wind) | Powder quantity adjustable | Fine powder | 30kW | |

Sieving system | 0~30mm | 160t | 160t | 0~3mm;3~4.75mm;>4.75mm | 15kW |

Others | 20kW | ||||

Total power | 360kW | ||||

SJ-300 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~120mm | 320t | 0~4.75mm(>70%) | 400kW | |

Feeding system | 0~30~120mm | 320t | 60kW | ||

Discharge system | 0~3mm(product) | 220t | 0~2mm(>40%) | 45kW | |

De-dusting system | 40000m3/h(wind) | Powder quantity adjustable | Fine powder | 45kW | |

Sieving system | 0~30mm | 320t | 320t | 0~3mm;3~4.75mm;>4.75mm | 22kW |

Others | 20kW | ||||

Total power | 592kW |

Note:

1.These parameters of sand production make limestone as a reference base.

2.Feed requirements in accordance with international standards, stone moisture is less than 5%.

3.Sand production will change according to different stone and raw material.

4.Designed by site-specific, picture is only for reference.

FAQ

1. Our Advantage

We are one of the largest State-Owned Enterprises in China which established in 1984 , has 30 years experience in stone crushing and sand making industry , have rich experience , We have professional R&D design department and technical engineer , we can make the design and suggest the suitable machine as per customer’s special requirement and any products is customized .

2. Quality Guarantee

We have Strictly Quality-Inspection Department and we also can apply SGS and other Third-Party Agency to check the Products to make sure superior quality .

3. Payment Terms :

Generally we accept TT and LC , if project requirement , we can accept DP and LC After Sight .

4. After Sales Service

We can send our engineer and sales manager to your job site for work and installation direction and make training for your workers .

5. Time of Delivery

We can overdo work for the customer to make sure the fast shipment

- Q: I never really listened to him but I've heard some of my friends say his one of the best, is he really a good rapper or what? If you think so could you tell me a good song by him so I could listen

- He fell off. I miss him tho. Lyrically, he wasn't all that, but he made good CRUNK music. Bone Crusher's Never Scared was his only popular song....he's done a number of features though

- Q: In the new SF: Legend of Chun Li movie... I just want to see an epic Bison Psycho pwnage lol

- Its possible, but they have been quite hush-hush about alot of the film's aspects. I know that this will not be the final film, becuase they want to have other characters have their own films. They have stated that Ryu and Ken will probably have their own origin story film, while introducing Gouken and Akuma.

- Q: It was hard to tell but I think the Shield would've pulled it off, and that is something hard to say when you're facing John Cena or Sheamus. I think they have a right to be tremendously upset.I think the Shield had it. I think they were going to be minutes away. But thank you to the Wyatts, the other team survived a scare.At the EC, let's go Cena or Sheamus.

- i'm ) have never done me wrong! have fun and good luck!

- Q: why are spherical roller bearing always used in crusher?

- Because it has a high load rating. Crushers indicate high loads on the bearing.

- Q: and how can we deny certain access list.plz give explanation?

- yes u should n the jammers r good because i use them as a cornerback

- Q: how to do m bison final psycho crusher with v-ism

- You can't do Super moves with V-ism, V-ism is for custom combos. To activate them press any two punch and one kick buttons together or any two kicks and one punch together at the same time when the meter is 50% or higher

- Q: Would you have told the truth if you were Wesley Crusher in the episode First Duty?

- Yes it's a little thing called honor. That really was a poorly executed episode.

- Q: I want to put it in the bottom of a vase. I want something like the fake water but harder and so I am able to put water on top of it without ruining or yellowing it. If anyone can point me in the right direction that would be great. If you also have an idea of where I could purchase this whether online or instore that would be awesome as well.

- noif you were never in the military you are not suppose to represent the military as if you were a member you can get in big trouble for that.

- Q: Is DB skull crushers good workout for your triceps?

- Yes, they are great for the triceps, and they can be done with dumbbells. Keep your focus on elbow movement. A bit of movement in the shoulder won't kill you.

- Q: The song that played during the King Kong teaser trailer and the youtube video quot;Crusherquot;? What is it called?

- can't help you out without link to vid. i don't know what video your talking about. there are none with crusher in the title.

Send your message to us

0-4.75mm Dry Sand Making System without any Powder in Site

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches