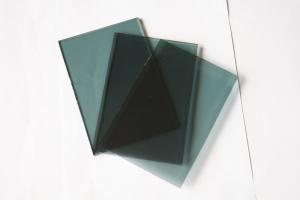

Parttened Art Glass 3mm 4mm 5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Square Meter/Square Meters m²

- Supply Capability:

- 8000 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Acid Etched Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass

Type: Float Glass

Packaging & Delivery of Parttened Art Glass

Packaging Details: packed in wooden cases

Delivery Detail: 15days

Specifications of Parttened Art Glass

1.Safety Glass

2.passed the 3C and ISO9001

3.UK-BS6206 Industrial Safety Standards

Product Features of Parttened Art Glass:

1 Safety

When laminated glass breaks, it stays in shape, keep glass integrity. The glass fragments will not splash and harm the people around.

2 Typhoon & Earthquake Resistant

When impact or force occurs, glass stays and will not break into pieces instantly

3. Sound Protection

PVB is able to absorb sound wave, subsequently create a quiet and tranquil environment.

4.Professional sales team, offering personalized and dedicated services

5. Full range of flat glass supply, offering one-stop purchase

6. ensuring convenient loading and rapid delivery.

7. Unique designed strong wooden cases, solving the problems of breakage.

8. Top quality glass with CE certificate,

- Q: Glass raw materials processing equipment, glass raw materials crushing equipment prices generally sell how much?

- 1. coarse crushing jaw crusher, 2. cone crusher, 3. sand machine, 4. screening machine, 5. finished products

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- There are ultra white solar glass. Dedicated to this solar energy

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- The first type of glass fiber reinforced plastics is a composite of glass fiber and phenolic resin. It is a glass fiber impregnated with phenolic resin liquid raw material, after molding, pre molding, and then the phenolic resin curing, made of glass fiber reinforced plastic. Corrosion resistance and long service life. Glass fiber reinforced plastic is a kind of high-quality composite material. It has a special anti-corrosion function for acid, alkali, salt, oil and other corrosive media, and will not rust. The average PVC life is 15 years, while the glass steel life is 50 years.

- Q: Is glass fiber reinforced plastic board fireproof partition board?

- A type of fireproof partition board. Glass fiber reinforced plastic sheet is flame retardant and does not support combustion performance. It can be classified into grade a fireproof board in fire prevention and fire fighting.

- Q: What is the raw material of glass? How is it converted to glass?

- Melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The price of raw materials is the largest proportion of quartz sand.

- Q: What kind of glass material is used in the aquarium?

- Float glassClear float glass is a paste by the control gate into the tin groove, due to gravity and surface tension of molten tin floating on the surface after re entering the glass Lengcao Xu, smooth, corrugated and made to disappear. Dark green, smooth surface, no ripple, good perspective, with a certain toughness.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- To the Chinese packaging bottle net glass bottle information, take a look at it, are glass bottle production technology and so on related articles, the only domestic bottle site.

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- Melting: mix into the glass melting furnace, at 1700 degrees of melting into glass liquid; 5, molding: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass; 6, annealing: the glass forming into the annealing furnace annealing, stress balance, prevent from breaking crack. Finally, inspection and packing.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 32.00% South Asia 18.00% Mid East 12.00% South America 12.00% Domestic Market 12.00% Eastern Asia 9.00% Southeast Asia 5.00% Central America |

| Company Certifications | Business Lisence |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang port,qingdao port |

| Export Percentage | |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Parttened Art Glass 3mm 4mm 5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 Square Meter/Square Meters m²

- Supply Capability:

- 8000 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords