Outdoor easy install DIY WPC tile/wpc flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Outdoor easy install DIY WPC tile/wpc flooring

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Outdoor easy install DIY WPC tile/wpc flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

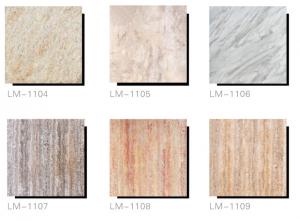

三.Outdoor easy install DIY WPC tile/wpc flooring Images

四.Outdoor easy install DIY WPC tile/wpc flooring Specification

Name | Outdoor easy install DIY WPC tile/wpc flooring |

Size | W*H=145*30 mm |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Outdoor easy install DIY WPC tile/wpc flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Plastic floor can be used indoors

- In our minds the plastic floor are generally used outdoors, such as the use of polyurethane (also called PU) made of PU silicon PU stadium and stadium, and our common stadium plastic runway and so on, because the plastic floor will release some harmful substances, it is generally not used for indoor sports venues. But there is also a material PVC in our plastic floor, which is specially designed for indoor use.

- Q: Ask how to install plastic floor

- As for the floor tile, marble, please joint groove to fill the soil with lime or cement to fill. Three, the original floor if the thickness of the wooden floor to be more than 12MM, there can be no bending, deformation or cracking phenomenon, such as to see the nail head must be buried in the wood. Four, the original floor if the cement can not have sand, bump or turn the situation. As for the new cement shop must be completely dry before construction, must be more than two weeks in the summer, winter will be around in the above, such as cold and wet climate will slow the rate of drying.

- Q: Basketball court assembled plastic floor why pack

- Suspension flooring: 1 special matte technology, 2 green, 3 simple and convenient installation, assembling 4 basketball versatility, 5 wear non slip durability, high ratio of 6, 7 low maintenance cost.

- Q: Heard that there is a special plastic floor nursery? What are the benefits

- Decorative strong: floor design is a very important part of the kindergarten environmental design. Children from the first step into the park, the first to attract their attention is the color, followed by the image, the last is the text. Children are in an important period of physical and mental development and rapid development. Therefore, the kindergarten plastic floor according to the children's imagination and association of color and psychological feelings, through the floor color and pattern design, to give children a healthy, happy, positive space environment

- Q: Badminton plastic floor? Want to be a sports venue, which plastic sports floor brand is better

- Badminton plastic floor with shock absorption sports protection to enhance the friction of the ball to provide better sports experience is very worthy of choice

- Q: What glue paste on plastic floor

- Generally, the use of water-based glue, look at the place of use, resin glue can also, or two-component glue, water-based glue to add other materials

- Q: Plastic foam on the floor there is no effect of moisture

- The mat is composed of a layer of plastic film and polyethylene foam bonding, and this layer of film thickness and toughness of the material is very good, is not an ordinary plastic film, so if the floor is laid directly on the ground, direct contact is no problem, moisture below the floor on the floor around the room of the joint direct expansion the release, so there is no problem of ventilation

- Q: How much is a square floor of plastic floor?

- This is a suspended floor, mainly used for laying floors. Specific prices need to be priced according to your needs, and now has a new suspension of the floor to install the construction of convenient, simple maintenance, will not be encountered before the old suspension floor wind blown phenomenon. You are our generation of suspended floors

- Q: What are the main construction process of laying plastic floor

- Construction pointsGrassroots should reach the surface not sand, not skin, not grey, no hollowing, no grease. Touch without roughness. If the requirements are not met, the ground should be treated first.The positioning line pop-up perpendicular to each other, and according to the laying of parquet patterns.The back surface of the base plate and the plastic floor plate is coated at the same time, and the adhesive surface can be posted when the adhesive surface is not sticky.The bulk of each with a piece of, will more than rubber extrusion in a timely manner with clean cotton silk.Paving is completed, it is necessary to promptly clean the floor surface, the use of water-based adhesives can be wiped with a damp cloth, the use of solvent based adhesives, the use of turpentine or gasoline to wipe the gel marks

- Q: Shop: composite floor below the moisture with plastic mold moisture do?

- The second is ground mat. The mat is composed of a layer of plastic film and polyethylene foam bonding, and this layer of film thickness and toughness of the material is very good, is not an ordinary plastic film, so I know if the laying of the floor directly on the ground, direct contact is no problem, the moisture in the floor around the room floor expansion joint direct release, so there is no problem of ventilation, also to cushion the plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor is used in the material, do not believe you can ask it to. Laying on the ground, a damp proof and moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant

Send your message to us

Outdoor easy install DIY WPC tile/wpc flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords