oor Decking Production Line, Metal Decking Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

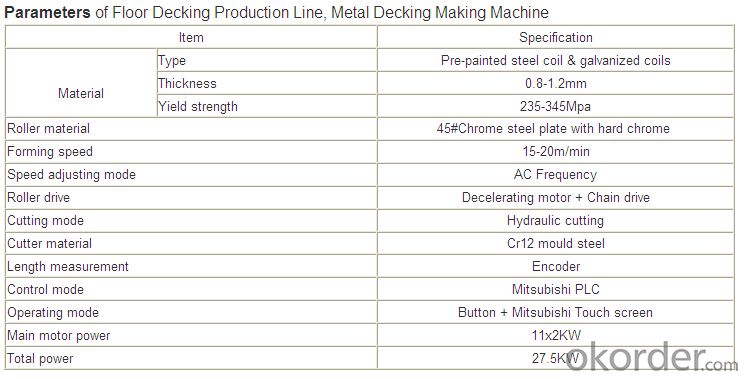

Quick Details

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Zhongyuan

Model Number: ZYYX

After-sales Service Provided: Engineers available to service machinery overseas

Application: floor deck panel forming

Control: PLC

Cutting mode: Hydraulic cutting

Length measurement: encoder

Shaft: grand twice, ID 82mm

Weight: 15ton

Main machine dimension: 16m(length) x 1.8m(width) x 1.6m(height)

Installation dimension: 20m(length) x 3m (width) x 1.8m (height)

Operation language: English or your required language

Packaging & Delivery

| Packaging Details: | 1. one 40ft and one 20ft container for loading one set machine with mechanical decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

|---|---|

| Delivery Detail: | 60 days after receipt of deposite and sign contracts |

Why choose this machine?

1. Designed by 15 years experienced R&D members with lifetime services.

2. Introduced Mitsubishi PLC with touch screen.

3. Need only one worker (minimum) to operate

4. Roller cover with 0.05mm chrome, ensure lifetime>10years

5. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

6. Product cut-to-length.

7. 82mm diameter solid steel shaft

Certificate: ISO 9001, CE,

Machine components:

Decoiler (manual decoiler and hydraulic decoiler for option) 1 set

Feeding & guiding device 1 set

Main roll forming machine 1 set

Hydraulic cutting system 1 set

Controlling system 1 set

Run out table (auto. Stacker for option) 2 pcs

Components spec.:

1. Decoiler Max. Capacity: 5000kgs

2. Hydraulic station power: About 5.5Kw (Depend on final design)

3. Control system: Mitsubishi PLC with touch screen

4. Cutting length: Cut-to-length

- Q:What is the main part of CNC machine tools?

- The basic components of CNC machine tools include machining program carrier, numerical control device, servo drive, machine body and other auxiliary devices.

- Q:The Function of Machine Tool Body in CNC Machine Tool

- Its function is to support the mechanical parts and components of the body, and to ensure that these parts industry in the cutting process in the exact location.

- Q:Compared with ordinary machine tools, how to look at the inevitable emergence of CNC machine tools

- Second, the accuracy of CNC machine tools can be used to achieve a clamping a number of surface processing to ensure the consistency of the size.

- Q:What is rocker machine, gantry machine? Are these two types of machines belonging to the same classification method? Are there any other machine tools in this category?

- Rocker machine: only heard of a radial drilling machine, the other is not necessarily not, but I did not hear.

- Q:CNC lathe programming g90 what it means

- HNC CNC lathe G90: absolute value programming.

- Q:What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- check the lubrication system oil storage parts of the oil should meet the requirements, closed well. Oil standard, oil window, oil cup, grease nozzle, oil

- Q:What is the meaning of CNC machining?

- Compared with ordinary machine tools, CNC machine tools have the following characteristics: ● high precision machining, with a stable processing quality; ● can be multi-coordinate linkage, can process complex parts; ● processing parts change, generally only need to change the NC program

- Q:What is the machine?

- Machine is the machine that makes the machine, also known as the machine tool or machine machine, used to be referred to as machine tools.

- Q:What is the main work of CNC machine tools?

- , high precision machining 3, processing stable and reliable, to achieve computer control, excluding human error, parts of the processing of good consistency, stable and reliable quality.

- Q:What is the meaning of R in the data lathe?

- CNC lathe: the digital program control lathe short, set universal lathe, high precision machining precision lathe and high processing efficiency of the special type of lathe in one, is the largest domestic use, the most extensive coverage of a CNC machine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

oor Decking Production Line, Metal Decking Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products