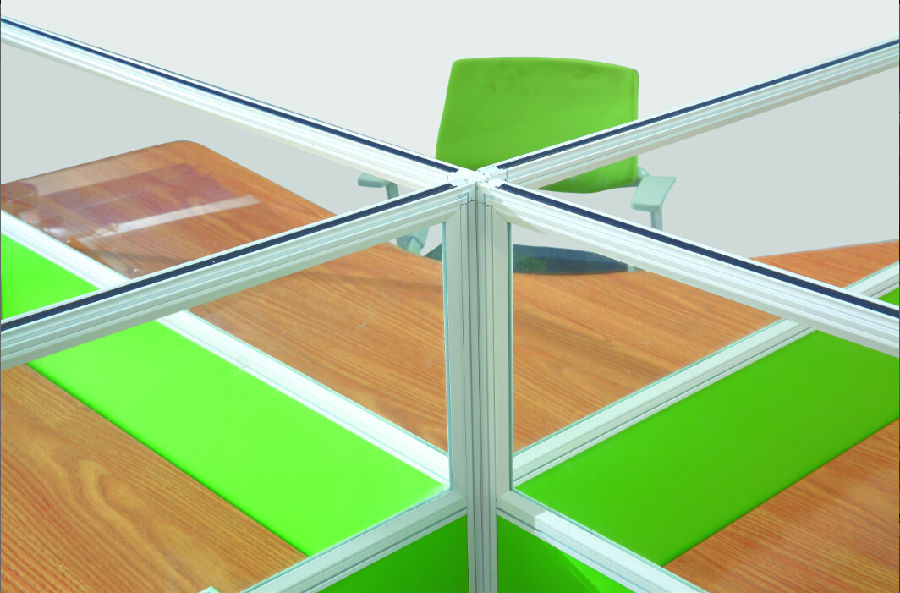

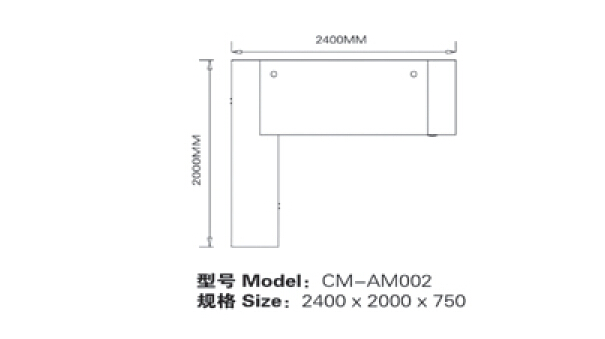

Office Table/ Excutive Desk Modern Wooden MDF Melamine/Glass Modular AM688

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*1200*1100 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q: What are the differences in cost between bamboo plywood and plywood and their respective uses?

- Bamboo plywood belongs to one kind of plywoodPlywood is a wide range of words: including bamboo plywood, wood plywood, plywood, and so onThe general comparison of construction is the difference between bamboo plywood and wood plywood

- Q: What is the thickness requirement of the insulation board in the distribution room?

- General appearance requirements:1, the insulation plate edge neat, no crack.2, bubble per square meter range, the area of less than 1 square centimeter of bubble may not exceed 5. The spacing between any two bubbles shall not be less than 40mm.3. The depth and length of the impurity shall not exceed 1/6 of the thickness of the insulating plate.

- Q: What is the difference between solid wood composite board and plywood?

- Process difference: multi-layer solid wood flooring and each slice will adopt scientific elimination of internal stress, arranged in a crisscross pattern, at present, the layers from the 7 layer to the 9 layer, 11 layer range; and general splint or plywood layers according to needs, relatively less in the balance of internal stress on the demand is far better than multi-layer solid wood this is our floor strictly, the daily common splint or plywood bend reason.

- Q: What kind of glue does bamboo plywood use in general?

- By using the manual blank, the blank is strictly divided according to the symmetrical principle, odd layer principle and the vertical texture of the adjacent layer bamboo. Bamboo panels are required to be made of good material, and bamboo pieces with lower material are used as backboard. Face and back of the bamboo chips outward oriented in core plate group tabasheer; blank, is toward the adjacent bamboo sheet are orderly arranged according to the bamboo chips, bamboo yellow alternate.

- Q: What are the specifications of plywood?

- The physical and mechanical properties of plywood can be explained by moisture content, density, thermal conductivity and bonding strength. The international standard organization on the production of ordinary plywood, from the structure, finished product moisture content, quality of 3 aspects of the provisions: 1. The texture of the veneer of the adjacent layers should be at right angles to each other; each layer is symmetrical with respect to the central layer; the thickness of each layer is the same; the surface and the back panel face outwards. Moisture content. Between 12~14% (according to China's national standards, the absolute moisture content of type I and II plywood is not more than 13% on average, and moisture content of plywood III and IV is not more than 15%). Quality. The finished product shall have rectangular straight edges and distinct edges and corners. The minimum number of plies per nominal thickness shall comply with the relevant regulations.

- Q: About up to the use of modified rubber sheet!

- The price is almost the same, there is nothing particularly worthy of recommendation. Play mode, Qu Feng Tang, Shangzhi toys, roaming model, Qu Feng Tang, the KING model, they generally have a sheet, you see what love style!

- Q: Pressing process of plywood

- Plywood is one of the commonly used furniture materials. It is a kind of artificial board. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three commonly used plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood. They can also be used in aircraft, ships, trains, automobiles, buildings and packing boxes.

- Q: What is the difference between plywood and veneer?

- Ecological plate is equivalent to generalized melamine veneer, its name is melamine impregnated paper veneer artificial board, is a different colour or texture of paper into ecological plate resin adhesive soaked, and then dried to a certain degree of cure, the cracks in the moisture proof board, particleboard, MDF, plywood, fine wood board or other hardboard surface decorative plate formed by hot pressing. 2. the narrow sense refers only to the middle ecological plate used as the substrate of multi-layer solid wood (plywood), blockboard (such as Malacca, fir, Paulownia and poplar) of the melamine decorative panel. Mainly used in furniture, cabinets, wardrobe, bathroom cabinets and other fields.

- Q: What is the difference between multi-layer solid wood flooring and plywood?

- Many consumers are the parquet mistaken for plywood, the main reason is that they have a lot of similarity in structure. But the two are linked, but there are differences. Contact is the core layer multi-layer parquet flooring for special plywood, the necessary requirement for the above full Ashikaga Risani etc.. The difference is that plywood is only one of the many ingredients for making multilayer solid wood flooring.

- Q: Can the insulating rubber sheet be towed by water?

- It can be towed by water. The insulating rubber plate is waterproof and won't be corroded by water.

Send your message to us

Office Table/ Excutive Desk Modern Wooden MDF Melamine/Glass Modular AM688

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords