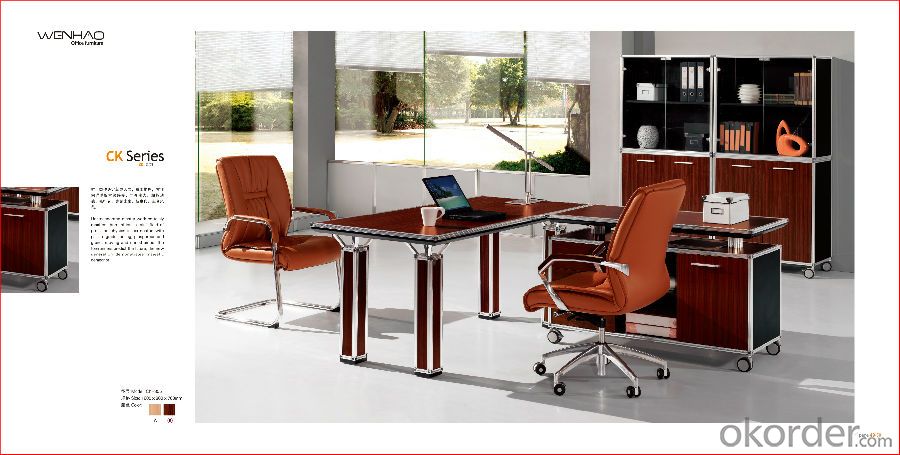

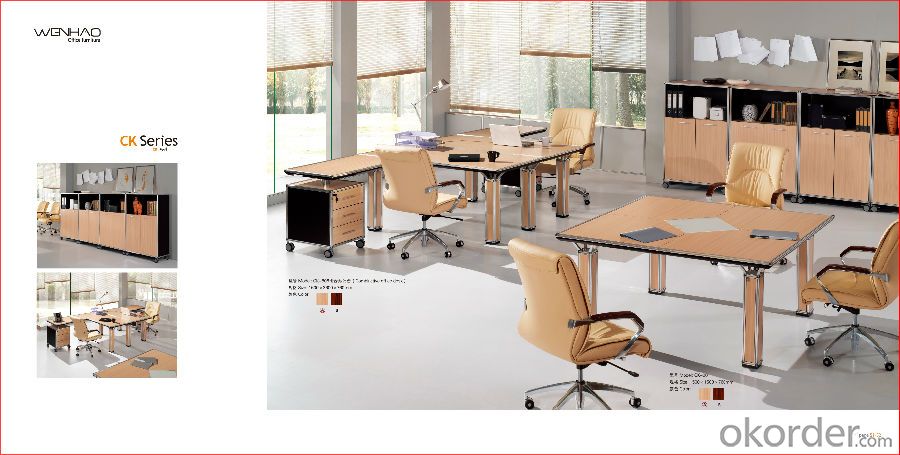

Office desk model-10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Descrpition: | |

| Model: | 12ET17 |

| Brand : | HOMEFELT Or OEM |

| Size: | 1800x800x760MM |

| Any Siz is available | |

| Material: | Good Quality MFC |

| Wood Thickness: | 25MM |

| Structure: | Main Table |

| Side Table and Movable Pedestal | |

| Style: | Modern |

| Export Years: | Over 1 years |

| Exported Countries: | Europe,Mid-East and America |

| MOQ: | One Containers mixed loading with different models at least 50pcs |

| Packaging: | Knockdown or Assembled Packaing as requests |

| Good quality Carton with printing as requests | |

| Payment Term: | T/T, LC At sigh, WESTERN UNION, MONEYGRAM or Cash |

| Trade Term: | FOB or EXW |

- Q: What is the difference between laminated lumber (LVL) and plywood (plywood)?

- LVL is also called "forward" plywood. Generally, the wood fibers of each floor are in the opposite direction. In this case, the consequent forces are relatively large. For structural problems, there are a few layers that will be horizontal, such as the two floor.

- Q: What is the thickness requirement of the insulation board in the distribution room?

- Electrical properties and thickness requirements of insulating rubber sheets:1, 500V below the distribution room, choose 5mm insulation board, power frequency withstand voltage test 3500V1 minutes, not breakdown; in power frequency voltage test 10000V, 20S shall not breakdown.2, 10KV below the distribution room, choose 8mm insulation board, power frequency withstand voltage test 10000V1 minutes, not breakdown; in power frequency compression test 18000V, 20S breakdown.3, 35KV below the distribution room, choose 10--12mm insulation board, power frequency withstand voltage test 15000V1 minutes, not breakdown; in power frequency compression test 26000V, 20S breakdown.

- Q: What material is good for siding?

- Wood grain artificial board: it is a kind of new decorative material on the surface of particleboard, fiberboard, plywood and so on. It is made of sand, light, greasy, oil, printed wood and so on. Its surface has precious wood texture and color, rich in layers, fresh, and wear-resistant, temperature, pollution, weather resistance, and waterproof, adhesion and other characteristics.

- Q: What is plywood?

- It is commonly known as plywood plywood, natural wood boiled softening, use of wood along the ring spin into large slices (veneer) in general 2.7mm thickness 20mm and above, according to the principle of symmetry, generally consists of three or more layers of a millimeter thick thin veneer, wood fiber layer adjacent to each other in the vertical blank, after drying, imposition, glue, hot pressing, glued into three or more layers (usually 3 - odd layer, 13 layer plate material). High quality product surface is smooth and smooth, without degumming, sand injury, press injury, no obvious color difference, no stains, good size processing accuracy, small thickness deviation, bonding strength 0.7Mpa, moisture content 6 - 14%. Usually used as substrates and panels, they can be used in building, interior decoration, furniture manufacturing, shipbuilding, packaging and other industrial products.Buy Plywood first, look at environmental protection. Depends on whether the release of harmful gases in line with national standards, especially the release of formaldehyde free glue is excessive. For these professional too strong things, most consumers may not clear, and can not be measured, so it is a shortcut to see whether manufacturers have environmental labeling products in china. Because to pass the certification, must be based on quality, environmental protection double standards as the premise.Next, look at the material. The price of different tree species is different. Consumers can choose different kinds of materials according to different demands. At present, the market is full of a large number of low price of Eucalyptus core plywood. In fact, this is the poplar core board made of surface coloring treatment, so the appearance of the board is basically the same, but the quality is very different. In fact, the core board, whether it is component or hardness, toughness, are higher than poplar core board, consumers should carefully identify when buying, so as not to be fooled.

- Q: Please master, simple and easy to tell me what is: plywood, composite board, the kind of wood powder pressed into what the board? What are their characteristics, please?

- The composite board is bonded with several boards, including plywood + MDF, plywood + decorative panel, MDF + melamine board, MDF + MDF and so on

- Q: About up to the use of modified rubber sheet!

- You can buy Tamiya, also can buy domestic. TB also have that kind of division of all kinds of width, generally speaking, 1MM thickness board used the most frequently.

- Q: What are the common thickness of bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material.

- Q: Is the plywood good?

- A kind of plywood for weather resistance, water resistance, durability of plywood, from here have advantages of high temperature resistance, steam treatment;The two kind of plywood is waterproof plywood, which can be soaked in cold water and soaked in short time;The three kind of plywood is moisture resistant plywood. It can be dipped in cold water for a short time and is suitable for indoor use at normal temperature. Used for furniture and general building purposes;Four types of plywood is not waterproof plywood, used in indoor normal, general use plywood beech, basswood, ash, birch, elm, poplar etc..

- Q: The difference between plywood and plywood

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.Plywood is one of the commonly used furniture materials. It is one of the three boards of wood-based panels. It can also be used as materials for aircraft, ships, trains, automobiles, buildings and packing boxes. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three common types of plywood plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood.

- Q: Plywood, furniture parts

- Plywood is of high strength and good bending resistance. In some of the structural areas that require load-bearing, the use of a thinner core will be more intense. However, the stability is poor due to the consistency of the core material. This allows the deformation of the core plate to increase. Therefore, the core board is not suitable for single sided parts, such as cabinets and so on.

Send your message to us

Office desk model-10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords