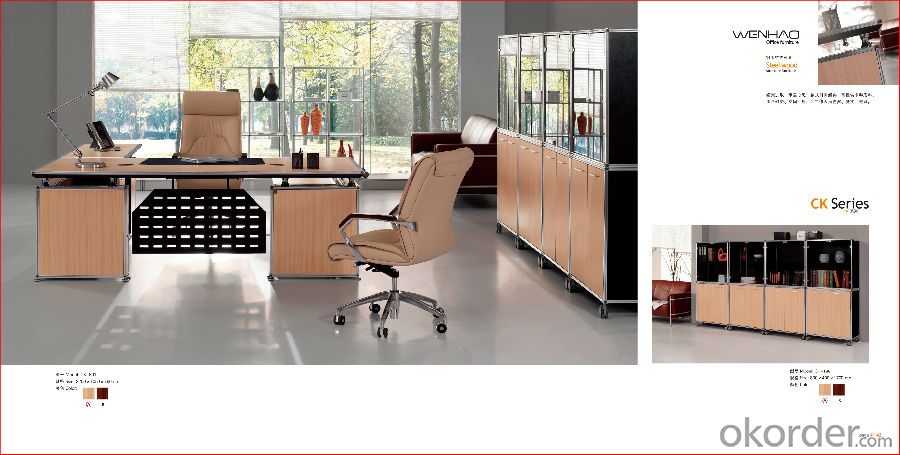

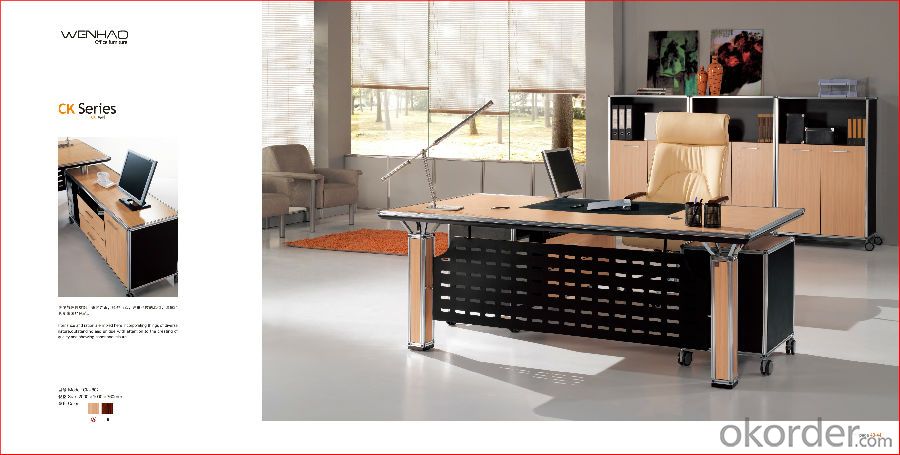

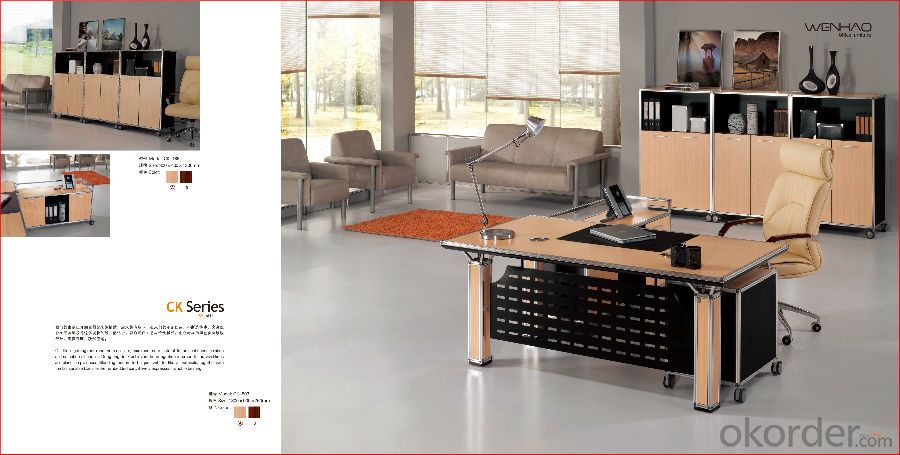

Office desk model-9

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Descrpition: | |

| Model: | 12ET17 |

| Brand : | CNBM |

| Size: | 1800x800x760MM |

| Any Siz is available | |

| Material: | Good Quality MFC |

| Wood Thickness: | 25MM |

| Structure: | Main Table |

| Side Table and Movable Pedestal | |

| Style: | Modern |

| Export Years: | Over 1 years |

| Exported Countries: | Europe,Mid-East and America |

| MOQ: | One Containers mixed loading with different models at least 50pcs |

| Packaging: | Knockdown or Assembled Packaing as requests |

| Good quality Carton with printing as requests | |

| Payment Term: | T/T, LC At sigh, WESTERN UNION, MONEYGRAM or Cash |

| Trade Term: | FOB or EXW |

- Q: What is the difference between laminated lumber (LVL) and plywood (plywood)?

- LVL is also called "forward" plywood. Generally, the wood fibers of each floor are in the opposite direction. In this case, the consequent forces are relatively large. For structural problems, there are a few layers that will be horizontal, such as the two floor.

- Q: How do you make the plywood process?

- Single plate - Section - log truncation wooden centering and rotary cutting veneer drying - processing - glue - cooling - Hot - embryo group and truncated - sanding test grading

- Q: What is LVL plywood?

- Veneer lumber, referred to as LVL, is to wood as raw materials made of rotary cutting or slicing veneer, drying, glue, or most of the grain by grain blank sheet by hot pressing, and then glued together, it has the structural characteristics of solid lumber have high strength, toughness, stability well, the exact specifications, ratio of solid lumber in strength, toughness increased by 3 times. This product can be used in building formwork components, building beams, car panels, furniture, floors, room decoration, wooden keel and packing materials, and so on. It has a wide range of applications.

- Q: What is plywood?

- Once again, look at the workmanship. Plywood plywood there are two differences between positive and negative. The time of purchase, to clear wood veneer surface, is smooth, smooth without delay to feel negative, at least not rough. It is better not to have scar section, even if there is, it should be smooth, beautiful, without affecting the construction, and will cause greater pollution. So choose, to see whether there is degumming, dispersol phenomenon, you can hand percussion parts of plywood, if the sound is crisp and uniform proof quality is good, if the sound muffled, uneven, said there has been the phenomenon of rubber powder splint.Finally, look at the appearance. When consumers buy, to see if there is a bubble, crack, hole, bruises, scar, defect and repair tape is too large and so on every piece of plywood, plywood is some two single in different lines of the stick together made, so the choice should pay attention to whether the clamp plate seams there is no strict, uneven phenomenon. The tight, irregular plywood made of furniture and doors and windows looks very unattractive.

- Q: What is the use of plywood in decoration engineering?

- Plywood is generally applied to situations where material strength and stability are relatively high. For example: Yunshan plywood is a soft Murray plywood, it can be used as houses, floors, walls and ceiling, covered with film can also be sprayed paint. The birch plywood with high hardness, film performance, can be installed directly, it can be used as concrete frame structure and floor formwork, container and other needs to do by the gravity of buildings and factory floor, scaffolding, do do LNG transportation isolation box etc..

- Q: Please master, simple and easy to tell me what is: plywood, composite board, the kind of wood powder pressed into what the board? What are their characteristics, please?

- The composite board is bonded with several boards, including plywood + MDF, plywood + decorative panel, MDF + melamine board, MDF + MDF and so on

- Q: What's the difference between a plywood press and a panel press?

- Hot pressing veneer, veneer veneer single double hot press, hot press, hot pressing system features: fast heating, heating system, heat conduction system of light carefully designed, low energy consumption, heat conduction mechanism design is reasonable, uniform; parts processing precision, wide adjustment range of process parameters, control process design is reasonable, can meet the requirements process for the production of veneer.

- Q: Do you make furniture, carpentry or plywood? Which one is more expensive?

- The plywood formaldehyde wood board is more than 2, but has the best technology on the plywood formaldehyde, make the effect, especially the edge look good, and not to brush paint, short time limit, you do when manufacturers custom-made hydropower, hydropower well directly on-site installation of furniture, save a long time this woodworking process. If high, better paint what.

- Q: What is bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material.

- Q: Plywood, furniture parts

- Five plywood, if higher requirements, you can use five plywood instead of three plywood surface layer;Nine ply is used for the baseboard of the base, door rabbet, window cover, furniture base base.

Send your message to us

Office desk model-9

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords