Polyfelt Ts Nonwoven Geotextiles for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nonwoven Geotextile Fabric for Road Construction Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

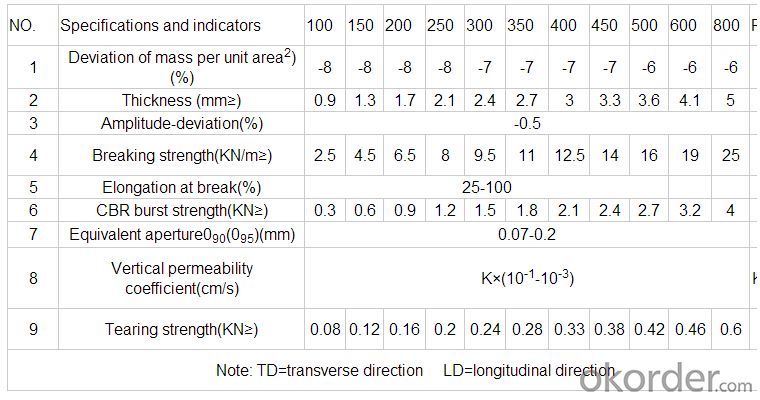

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: 300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q: Is there a geotextile between the waterproofing membrane and the rigid layer?

- Need to prevent the waterproof layer from being pierced. Huazhi geotextile material manufacturers

- Q: What are the different geotextile installation equipment and tools?

- Some of the different geotextile installation equipment and tools include geotextile dispensers, spreaders, rollers, staplers, and anchors. These tools are used to ensure proper placement and securement of geotextiles in various construction and environmental applications.

- Q: How do geotextiles help in groundwater drainage?

- Geotextiles help in groundwater drainage by acting as a filter and separator between the soil and the water. They allow water to pass through while preventing the migration of fine particles, thus preventing clogging of drainage systems. Additionally, geotextiles help in distributing the flow of water evenly, reducing the chances of localized flooding and promoting efficient groundwater drainage.

- Q: What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific material and application. In general, higher temperatures can cause geotextiles to expand and become less stable, while lower temperatures can make them more rigid and prone to cracking. Extreme temperature fluctuations can also affect the long-term durability and effectiveness of geotextiles. Therefore, it is crucial to consider temperature conditions when selecting and designing geotextile applications to ensure optimal performance and longevity.

- Q: What is the difference between a hard pipe and a mesh plastic blind ditch?

- Different products, all play the role of drainage ditch need to wrap geotextered soft water pipe does not require geotextile package. Huazhi geotextile material answer

- Q: Can geotextiles be used in erosion control in agricultural fields?

- Yes, geotextiles can be effectively used in erosion control in agricultural fields. Geotextiles are permeable fabrics that can stabilize soil and prevent erosion by retaining sediment and allowing water to pass through. They are commonly used in agricultural practices such as slope stabilization, soil erosion prevention, and filtration. By placing geotextiles in areas prone to erosion, they can help to reduce soil loss, improve water quality, and enhance the productivity and sustainability of agricultural fields.

- Q: Geotextile back to the pebble and geotextile bag what inspection batch

- I professional production geomembrane geotextile and other materials, wish smooth

- Q: Are geotextiles resistant to creep deformation?

- Yes, geotextiles are generally resistant to creep deformation. Geotextiles are designed to have high tensile strength and low creep properties, allowing them to withstand long-term loads and maintain their original shape and dimensions over time.

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

Send your message to us

Polyfelt Ts Nonwoven Geotextiles for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords