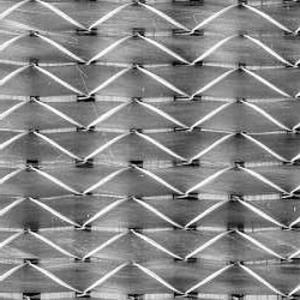

Fiberglass Mat Tissue Non Filament Crimp Fiberglass Multiaxial Warp-Knitted Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multi-axial fiberglass fabrics are made from Roving. The Roving placed parallel in each layer in a designed direction could be arranged 2-6 layers, which are stitched together by light polyester threads. The general angles of the placing direction are 0, 90, ±45 degree. Unidirectional knitted fabric means main mass is in a certain direction, for example 0 degree. It is applied for vacuum infusion or winding process and mainly used for the production of wind blades, pipes, and so on. They are available for epoxy (EP), polyester (UP), and vinyl resin (VE) systems. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ 1) How much sample can you provide and who will bear the sample cost? We can provide the glass fiber samples not more than 1kg free of change. However, the courier cost must be born by the customer. As to the glass fiber composite materials, we can provide the piece not more than 1kg free of change ( with the existing module). However, the courier cost must be born by the customer. If we need to make a new model, this excludes. 2) How can you guarantee the quality? We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Fiberglass mat tissue can be a suitable insulation material for cold storage facilities. Fiberglass is known for its excellent thermal insulation properties, which can effectively prevent heat transfer and maintain low temperatures in the storage area. Additionally, fiberglass is resistant to moisture and does not absorb water, which is important in cold storage facilities where condensation and moisture can be prevalent. The fiberglass mat tissue can be easily installed and provides a cost-effective solution for insulating the walls, ceilings, and floors of cold storage facilities. Overall, fiberglass mat tissue can effectively contribute to maintaining the desired cold temperatures and preventing any thermal leaks in these facilities.

- Q: What are the different weights available for fiberglass mat tissue?

- The different weights available for fiberglass mat tissue range from 20 grams per square meter (gsm) to 100 gsm.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Yes, fiberglass mat tissue does require special treatment for UV resistance. Without proper protection, the fiberglass mat tissue can degrade and weaken when exposed to sunlight and UV rays. Applying a UV-resistant coating or using a UV protective film can help enhance its durability and resistance to UV damage.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Indeed, fiberglass mat tissue is a suitable option for the restoration of fiberglass boats. This versatile material is frequently employed in the reinforcement and mending of fiberglass structures, especially boats. Its purpose is to supply robustness and endurance, rendering it an excellent selection for the rectification of fissures, breaches, or impaired regions in the hull of a fiberglass boat. Typically, the mat tissue is layered alongside resin to construct a firm and steady reparation, guaranteeing the structural integrity of the vessel. Furthermore, fiberglass mat tissue is user-friendly and can be tailored to the preferred size and shape, making it appropriate for a variety of repair applications on fiberglass boats.

- Q: Can fiberglass mat tissue be used for decorative applications?

- Yes, fiberglass mat tissue can be used for decorative applications. Its versatility and ability to be molded into various shapes make it suitable for creating decorative elements such as wall panels, sculptures, and other artistic installations. Additionally, its lightweight nature, durability, and resistance to corrosion make it an ideal choice for both indoor and outdoor decorative applications.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Indeed, fiberglass mat tissue proves to be a fitting option for railway rolling stock. This lightweight and resilient material is frequently utilized in the construction sector for a multitude of purposes, including the production of railway rolling stock. Its exceptional mechanical robustness and resistance to corrosion render it optimal for deployment in the challenging and rigorous settings characteristic of railway rolling stock operations. Furthermore, fiberglass mat tissue exhibits commendable thermal insulation characteristics, contributing to enhanced energy efficiency within the rolling stock. All in all, fiberglass mat tissue emerges as a suitable and dependable selection for the construction and upkeep of railway rolling stock.

- Q: How is fiberglass mat tissue used in the automotive industry?

- The automotive industry relies heavily on fiberglass mat tissue for various purposes. This versatile material offers numerous advantages, making it an ideal choice for multiple applications. Reinforcing composite materials is one of the primary uses of fiberglass mat tissue in the automotive industry. It is commonly employed as a reinforcement layer during the production of car panels, hoods, roofs, and doors. By enhancing the structural integrity of these components, the fiberglass mat tissue makes them more durable and resistant to impact and external forces. This reinforcement property contributes to the overall safety of the vehicle. Furthermore, fiberglass mat tissue is also utilized for sound insulation in the automotive industry. This material possesses excellent sound absorption properties, effectively reducing noise and vibrations within the vehicle. By incorporating fiberglass mat tissue in areas like the floor, doors, and roof, automakers can significantly improve the overall acoustic comfort of the vehicle, providing a quieter and more enjoyable driving experience. Moreover, fiberglass mat tissue finds application in thermal insulation within the automotive industry. Acting as a barrier against heat transfer, this material helps regulate the temperature inside the vehicle. By incorporating fiberglass mat tissue in areas such as the engine compartment, exhaust system, and undercarriage, automakers can insulate the vehicle from excessive heat, preventing overheating and ensuring optimal performance. In conclusion, fiberglass mat tissue is extensively used in the automotive industry for reinforcement, sound insulation, and thermal insulation purposes. Its versatility makes it an indispensable material in vehicle manufacturing, contributing to improved safety, comfort, and performance.

- Q: Can fiberglass mat tissue be used for making decorative panels?

- Yes, fiberglass mat tissue can be used for making decorative panels. Fiberglass mat tissue is a versatile material that is commonly used in the construction and manufacturing industries. It is made up of randomly oriented glass fibers that are bonded together with a binder. This combination of fiberglass and binder creates a strong and durable material that is suitable for a wide range of applications. When it comes to decorative panels, fiberglass mat tissue can be an excellent choice. It can be molded into various shapes and sizes, allowing for the creation of intricate and unique designs. The material is also lightweight, making it easy to handle and install. Additionally, fiberglass mat tissue has excellent dimensional stability, meaning that it will not warp or deform over time. Furthermore, fiberglass mat tissue is highly resistant to moisture, chemicals, and UV radiation, making it ideal for both indoor and outdoor applications. It can withstand harsh weather conditions and is not susceptible to rot or decay. This durability ensures that decorative panels made from fiberglass mat tissue will maintain their appearance and functionality for an extended period. In terms of finishing, fiberglass mat tissue can be easily painted or coated to achieve the desired aesthetic. It can also be laminated with other materials, such as wood veneer or decorative films, to enhance its visual appeal. This flexibility allows for endless design possibilities, making fiberglass mat tissue an excellent choice for creating decorative panels. In summary, fiberglass mat tissue is a suitable material for making decorative panels. Its strength, durability, and versatility make it a reliable choice for both indoor and outdoor applications. Whether you are looking to create unique designs or enhance the aesthetics of a space, fiberglass mat tissue can provide the necessary qualities to achieve your desired outcome.

- Q: Is fiberglass mat tissue suitable for insulation in pharmaceutical plants?

- Yes, fiberglass mat tissue is suitable for insulation in pharmaceutical plants. It is a commonly used material in various industries, including pharmaceutical, due to its excellent thermal insulation properties and resistance to moisture, chemicals, and fire. Additionally, fiberglass mat tissue is lightweight, easy to install, and can help maintain controlled environments, making it an ideal choice for insulation in pharmaceutical plants where maintaining proper temperature and cleanliness is crucial.

Send your message to us

Fiberglass Mat Tissue Non Filament Crimp Fiberglass Multiaxial Warp-Knitted Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords