New Style PVC Edge Banding for MDF / Particle Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

Type: Edge Banding

Place of Origin: Shandong, China (Mainland)

Model Number: ST8050

Packaging & Delivery:

Packaging Details: standard export sea worthy packing

Delivery Detail: 7 days

pvc edge band

Quick details:

Width 12~120mm or as customer require

Thickness: 0.4-3mm or as customer require

Material: Acrylic, PVC or ABS, environment friendly material as you required

Surface: Solid color, wood grain color, glossy surface or emboss surface

Packing way: thick≤ 1mm: 200m/R, 10R/BOX; thick >1mm: 100m/R, 5R/BOX

Payment term: T/T, or L/C at sight

Advantage:

1.High and low temperature and pressure resistance .

2.Excellent quality of printing ink and never fade in color.

3.No bubble on the surface and the texture is clear.

4.Marvelous quality of primer, homogeneous and never fall from the furniture.

5.Mildew proof, anticorrosive, oil resistance, non-toxic, fire resistance.

6.safety and health

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

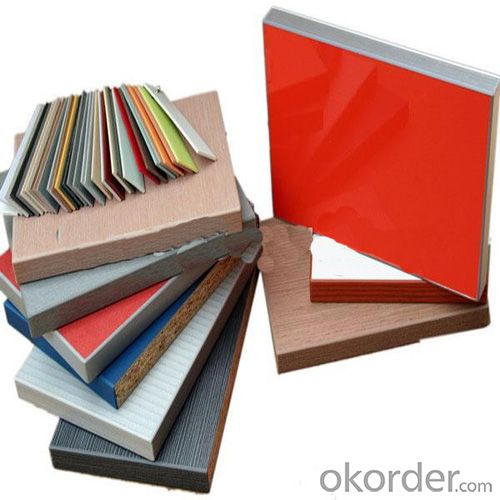

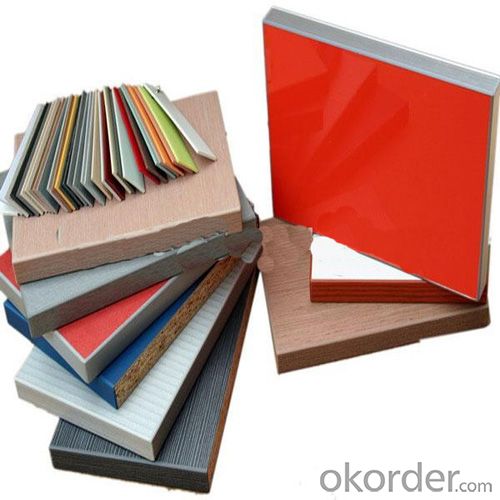

Product Show:

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: Rock wool color steel sandwich board rock wool bulk density

- 120 ~ 150kg / m ^ 3 Depending on the temperature difference, the temperature difference in the 130 ~ 180kg / m ^ 3 Attached to the industry standard

- Q: How about the use of colored steel sandwich panels on the balcony

- Can you, inexpensive. Just when the rain is relatively large noise, lighting effect is not ideal If the conditions permit, then recommend the use of glass, 5 +5 plus plastic on the line. The price difference of about 30%. Life is longer than the color steel, low noise, good lighting.

- Q: Specification for thickness of steel - wool sandwich panel

- Color steel rock wool sandwich panel specifications are: 950, 960, 1150 type, rock wool thickness is divided into: 50mm, 75mm, 100mm, 150mm

- Q: What brand of rock wool sandwich board is good

- Shandong Yongguang building materials technology companies to produce rock wool composite board has more than 10 years of history, is located in Jiangbei largest steel production base - Zibo Zhoucun, color steel plate, rockwool core material, such as a complete upstream and downstream industry chain, Has an unparalleled low cost advantage. Save money is the last word! Welcome to the majority of steel installation company to visit.

- Q: What is the glue used in color steel sandwich panels?

- Color steel composite panels are used this. It is easy to buy on the market

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- There are six kinds of core material: polystyrene sandwich panels that EPS sandwich panels (the market, the most widely used varieties); Extruded polystyrene sandwich panels that are XPS sandwich panels; Rock wool color steel sandwich panels Rigid polyurethane sandwich panels that PU sandwich panels; Trimer sandwich panel that is PIR sandwich panels; Phenolic sandwich panels that are PF sandwich panels; Rock wool sandwich panels are RW sandwich panels. Product performance: thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm, 960mm.950mm Scope: workshop, office walls, steel structure of the external walls Maintenance, decorative building materials, activities, such as office buildings Fire rating: B1 ~ B3 (flame retardant: melting) Moisture absorption: 3.9 (%)

- Q: Rock wool sandwich panels up and down the interface how waterproof

- With a butyl water seal tape placed in the overlapping position.

Send your message to us

New Style PVC Edge Banding for MDF / Particle Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords