Geotextil Antipunzonante Needle Punched High Strength Non Woven for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Needle Punched High Strength Non Woven Geotextile:

Short fiber pet geotextile is through the non-woven production equipment of opening, carding and clutter (short fibers intertwined together), web (fixation) normalized tangles, acupuncture and other production process made of cloth.

Main Features of Needle Punched High Strength Non Woven Geotextile:

1,Good glexibilty

2,permeability

3,filtration

4,separation

5,easy for constrution

Specifications of Needle Punched High Strength Non Woven Geotextile:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

| Packaging | packed in roll or as the customer's requirements |

| Delivery | 10 days after get the deposit |

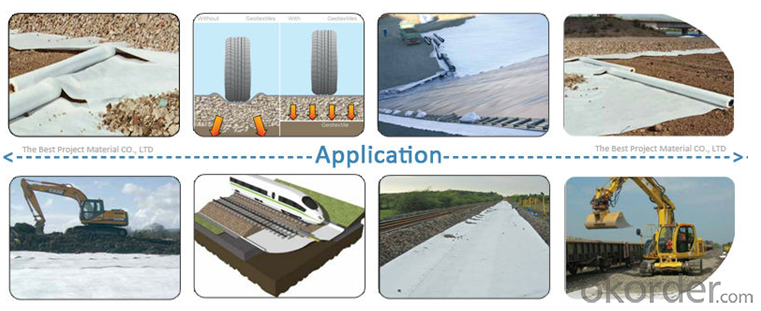

Applications of Needle Punched High Strength Non Woven Geotextile:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

IMages of Staple Fiber Needle Punched Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is a geotextile?

- A geotextile is a synthetic material specifically designed for use in various civil engineering and construction applications. It is typically made from polyester or polypropylene fibers and is used to stabilize soil, separate different layers of soil, and provide drainage and filtration in infrastructure projects such as roads, landfills, and retaining walls. Geotextiles are essential in preventing soil erosion, improving soil strength, and increasing the lifespan of infrastructure projects.

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer several benefits in construction projects. Firstly, they provide excellent soil stabilization, preventing erosion and maintaining the integrity of the structure. Secondly, they enhance drainage and filtration, allowing water to flow through while retaining soil particles. Additionally, geotextiles act as a barrier against weed growth, reducing the need for chemical herbicides. Lastly, they improve the overall lifespan and durability of the construction by reinforcing weak areas and distributing loads evenly.

- Q: Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles serve as a separation and filtration layer, preventing the mixing of soil particles and providing added stability to the wall structure. They can help distribute the load across the wall surface and improve the overall performance and longevity of the retaining wall.

- Q: Can geotextiles be used in the construction of artificial ponds?

- Yes, geotextiles can be used in the construction of artificial ponds. Geotextiles are often used as a lining material for ponds to provide reinforcement, filtration, and separation between the soil and water. They help to prevent erosion, control soil movement, and improve overall stability of the pond structure.

- Q: We are scrambling to sell geotextiles, recommended geotextile. What is the principle of geotextile seepage? Why can geotextile seepage? More

- Geotextile impermeability depends mainly on the anti-seepage properties of plastic film. Is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber.

- Q: Are geotextiles biodegradable?

- No, geotextiles are typically not biodegradable.

- Q: What is a polyester filament geotextile? Polyester filament geotextile

- In addition to a good mechanical energy, but also has a good vertical and horizontal drainage and good extension of energy and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, also has a wide range of pore size, tortuous pore distribution, excellent permeability and filtration can be polyester filament geotextile purposes: water conservancy project dam and slope protection filter, channel isolation, seepage; Airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage; port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile Has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas. Polyester filament geotextile technical parameter table (GBT-1998): No. Remarks 1 unit area mass deviation% -6-6-6-5-5-5-5-5-4-4-42 thickness, mm ≥ 553 Width deviation% -054 breaking strength KNM ≥ vertical and horizontal 5 elongation at break% 40-806CBR breaking strength KN ≥ 707 equivalent aperture 090, mm007-02

- Q: How do geotextiles help with soil separation and stabilization?

- Geotextiles help with soil separation and stabilization by acting as a barrier between different soil layers, preventing mixing and maintaining their individual characteristics. They also enhance soil stability by increasing its shear strength, preventing erosion, and improving drainage.

- Q: Geotextile (two cloth a film) to detect the frequency requirements? On behalf of the number?

- Geotextile and geomembrane detection frequency is 100 volumes detection time.

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

Send your message to us

Geotextil Antipunzonante Needle Punched High Strength Non Woven for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords