MODEIFED SILICON PREPAINTED ALUZINC STEEL COIL FOR PRODUCTION ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

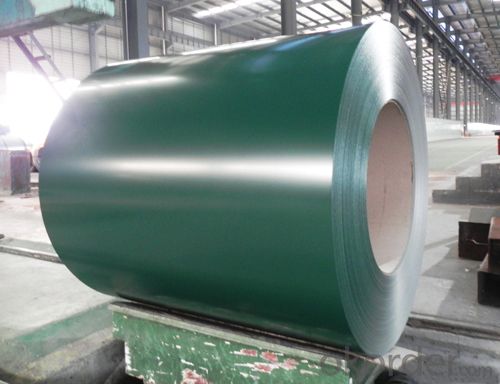

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How clients can follow up the order procedure?

We have effective ETP working systerm and opened okorder-in service for every client.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How to maintain glasses glasses frames

- Glasses can be sent to the optical shop for ultrasonic cleaning, the general optical shop has this service. 1, tighten the screw: If the screws are loose, please get the glasses shop or yourself personally tighten, otherwise the glasses are easy to fall on the ground to break or scratched. 2, to keep clean: sweat or oil on the skin easy to corrode the metal part of the corrosive effect, cleaning glasses every day, to extend the life of the glasses very helpful. 3, the correct fold: most of the glasses are from the base side of the mirror gently folded, if the hard from the right first fold, will lead to the frame itself is not balanced, skewed, so you wear after the uncomfortable. 4, the correct mirror: wiping with a special cloth glasses. Do not touch the lens hard objects, do not wipe the lens with your fingers, please use a clean mirror cloth to wipe, reduce lens wear. 5, the correct storage: the front of the lens do not put down. If you do not, try to put glasses box, glasses, if not wear, please use a mirror cloth will be wrapped in glasses, into the mirror box, so as not to damage. 6, the right to wear: wear glasses with one hand, easy to make frame deformation. Frames if the variant, should find the local glasses master adjustment angle, do not adjust their own, so as not to break the lens, damage the frame. 7, to avoid the sun: a long time on the sun easy to place, because the frame in the light and thermal decomposition, easy to fade. Precautions: Correct care glasses will do: the lens should always wipe, the frame often care, glasses should always wear. Glasses are to help patients with myopia correction of vision tools, we have to correct care, not because of improper glasses and affect the effect of corrective vision.

- Q: Now I have to come up with a E1 level test report, but I want to buy E0 level, but the staff of Loulan Ya said that there is no E0 level of this concept. Is this true? Please industry experts to answer the next

- Customized furniture can be made of E0 grade sheet.

- Q: Will the 2017 plate 10 brand quality how?

- Ranked by quality, the New Zealand Pavilion is a well-deserved first. New Zealand Chilean plate benefited from New Zealand's unique island climate, and in the case of the ever-decreasing natural forests in the world, New Zealand Wood has grown well as a sustainable renewable resource. Zhige plate selection of trunk high, light color, solid wood, very suitable for furniture manufacturing and a variety of decorative wood applications.

- Q: Home improvement wardrobe what brand plate best

- Custom cabinet, then the general is solid wood particle board (high density board), melamine board, particleboard. The advantages of this plate is the factory production, workmanship, the disadvantage is not enough nail force, a nail out of the words, you can no longer fixed. On-site cabinets are more common is the lacquered board and blockboard, deformation-resistant blockboard is better than the lacquer-free board. From the environmental aspects of the paint-free board is relatively better than the blockboard, because the blockboard with rubber is relatively more, but if you choose a good brand this is not how much the problem.

- Q: Very grateful to xiaokaikaiya, AAA forgot to hide 8, 100 plate _ business; the origin of this issue I elaborate: late this year I ride a motorcycle to go to China, Sichuan, Tibet, the new line, two cars and equipment a total of about 900 I will be equipped with two side boxes and a trunk, the three boxes are 7075 material, a single box with stents are about 8 kg, three boxes a total of about 24 kg, due to The vehicle carrying equipment is too heavy lead to tire wear serious, more than 14,000 km new tire completely worn out, so I want to use the new material to re-create the side box, on the one hand to reduce the weight, but the material strength can not be reduced, because the motorcycle reversing When the side box can be used with the front bumper to form an effective protective space, the protection of the human leg and vehicle protection is very significant! The ??? Do not know whether the above statement is clear, there are problems you can contact.

- I simply said that you can use light steel keel. Hundred bai strong have this ah

- Q: First, the backplane is generally 9MM, the door is generally 15MM, the cabinet is generally 18MM, the reasons are as follows, the cabinet is shaped, basically rarely move it, 9 thick wall, without any strength, cost Reduce the door to do the paint, both sides of the panel also add up to 15 +3 * 2 = 21, do not say, the general plate can not do paint, must be decorated panels, and drawers with nine thick floor , Taking into account the drawer space and weight problems, the use of convenience, as well as the aesthetic degree, so that, so that the cost is reduced, without affecting the use, and beautiful, if it is a board furniture finished cabinet, may use 18MM , Taking into account its stability

- Plate furniture is not really good if the back of the wardrobe with a thin backplane is even more ideal you will feel the cabinet will shake the drawer floor is too thin will collapse

- Q: What is the board for the speaker

- 200MM above the high-density board can be a little thick panel, do a good job after filling the sound-absorbing cotton

- Q: Why construction of temporary building blocks in construction technology?

- Support temporary square wood is to set up by the wall. Temporary square wood above the wood and the bottom of the wood. The top of the wood can be directly on the top of the line in the top of the structure of the ground, the bottom of the wood can be about 100mm from the ground floor, between the upper and lower wood every 1.5m or so stand supporting the side of the wood, and wooden wedge will be between the lower wood and supporting wood between the wedge tight. Temporary square wood support, you can install partition board.

- Q: Natural granite stone plate according to its surface level of processing can be divided into three categories

- 1, fine panel (RB). It is a smooth, smooth sheet. 2, mirror sheet (PL). It is a flat surface with a glossy glossy sheet. 3, rough panel (RU). It is the surface smooth, rough, with more regular processing of the stripes of the plane board, chopped ax plate, hammer plate

Send your message to us

MODEIFED SILICON PREPAINTED ALUZINC STEEL COIL FOR PRODUCTION ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords