HIGH-DURABLE PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

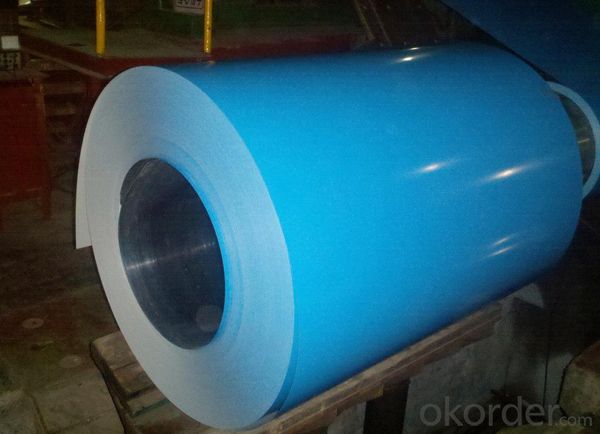

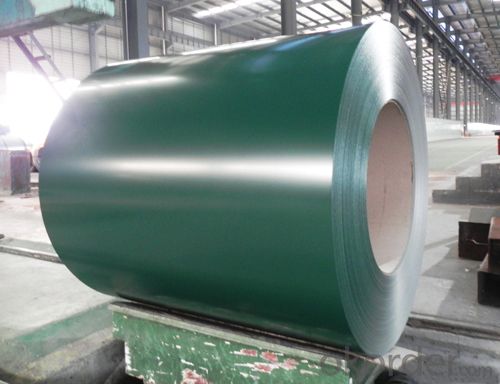

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your qality?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;we can make sure 10 years life.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Is the PS board not an acrylic board?

- PS board and acrylic board is not a board. PS plastic components, poor transparency, Pan-blue, not wear-resistant, the price is low, does not apply to the word, you can do some of the appropriate splint painting. Acrylic board is extracted from the oil, high transparency, good wear resistance, the price may be higher, apply to do light boxes, crystal characters, transparent panels, cosmetics display stand, there is the company's LOGO wall are using acrylic To do it.

- Q: Black box plate glasses for what kind of person

- If the election is more affinity Recommend the kind of color plate Black is the main color, in the edge of the box through the other colors Bright pink and bright blue are good But also a little round of the black box Not the kind of side (some formal) Or when to pick the time to see There is the kind of wrapping a little more upset That kind of wear will be very cute

- Q: How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q: My family's kitchen seven-shaped, the amount is a total of four meters, one meter over the top cabinet, put a hood in the middle. Under normal circumstances if the woodworking need a few fire board? Do you need a few sheets?

- Cabinet fire board needs an area of 9.4 square meters (including) inside the partition, the specific area of how much (depending on how much), a sheet of 1.22 * 2.44 = 2.97 square meters, estimated the need for fire board (with loss) Four, even the top cabinet came out (these are counted on the table). Door area of about 4 square meters, count down 1.36, the door needs to buy two, but also some of the rich plate. Above for reference, if any access please do not see strange.

- Q: Look at the brand of wardrobe quite nice but offer too high. So I would like to buy their own plate to find wood workers to do. What sheet is good?

- 18 cm sandwich panels, wood keel, omnipotent boulder lines Pauli board panel drawer track and door hinge paint on the polyester primer with the finish

- Q: Stainless steel sheet thickness of about 0.6 thick thick mm

- 0.5-0.6 thickness you have to see how much thickness you need

- Q: Bunny plate environmental protection China line advertising

- Actually become such a sheep to eat it, she said the company is scheduled to cheat, people fooled to distant remote exhibition to ask her reason, long mind people know that this is a guise price activities, everyone only A live card on the 50, and a variety of Huyou, I would like to ask the head office you really is a set of online, said a good 50 yuan so-called activity card into 100, the day to so many people , Can imagine how much the income

- Q: Daren detailed explanation VCM color plate and PCM color plate difference, for the refrigerator panel

- VCM board for the film, PCM for the color coated board, the general VCM board with galvanized substrate, covered with color or pattern film, the surface of such a plate is very smooth, the surface color effect is PCM can not be achieved, but the price More expensive, generally used in the refrigerator panel, or high-end wine cabinet side panels, set-top box shell, product use for the membrane requirements have a relatively high demand. PCM is a color pre-coated sheet, the surface for home appliances environmental protection paint, the price is relatively cheap compared to PCM, generally used in the refrigerator side panels, this plate is not suitable for high-grade refrigerator panel, due to the flatness of the plate than VCM difference and color The effect is single, so the main use of the side panels.

- Q: The difference between plate and wire

- Simple description, the plate is the whole, you can arbitrarily deep processing, arbitrary cutting, the standard size is 1220mmX2440mm. The wire is usually semi-finished products, not free processing, important, common engraved lines, door lines, pressure seam lines Etc., is a parquet, a group of pictures, decorative materials, and sometimes play to cover up, make up, the finishing touch.

- Q: Plate market, the so-called eight major markets, where is the four bases?

- Shandong Province Linyi City Yitang Town Hebei left the village of China's four northern man-made board production base in Jiangsu Pizhou and Suqian, Shandong Linyi and Heze Shandong Linyi, and a few Yintang town plate manufacturers,

Send your message to us

HIGH-DURABLE PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords