Mill Finished PVDF Coated Aluminum Composite Panels - EN AW-3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels Description

Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

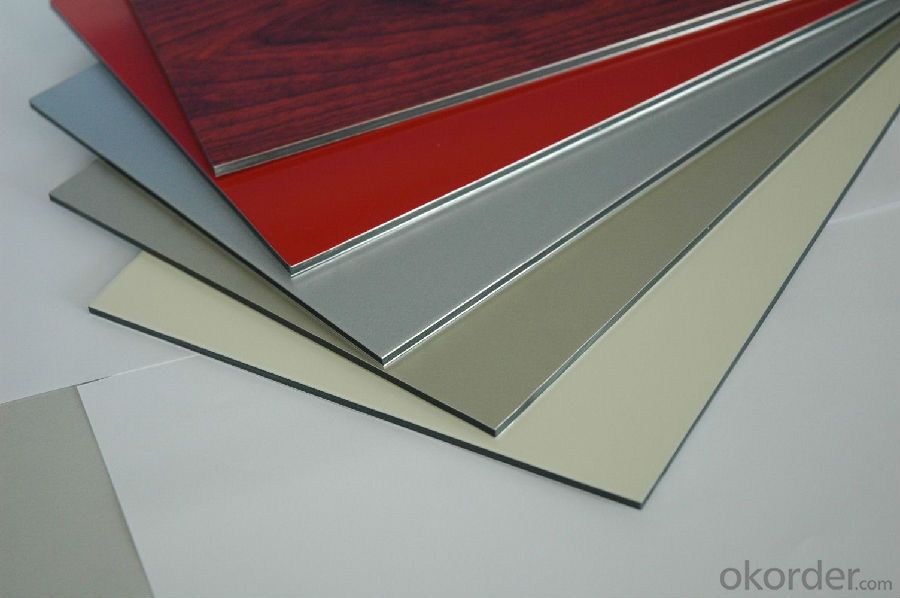

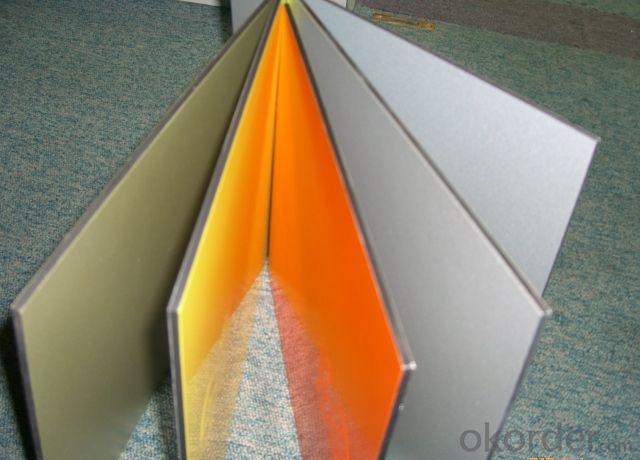

6. Image of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

7. Package and shipping of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for recent advancements or innovations in the technology related to aluminum.

- <p>Recent developments in aluminum technology include the advancement of aluminum-air batteries for energy storage, which offer a more sustainable and efficient alternative to traditional batteries. There's also the development of nanostructured aluminum alloys that exhibit superior strength and lightweight properties, making them ideal for aerospace and automotive applications. Additionally, research into aluminum recycling has led to more efficient processes, reducing waste and environmental impact. Lastly, advancements in aluminum electrolysis have improved energy efficiency, contributing to the sustainability of aluminum production.</p>

- Q: Is aluminum a suitable material for use in electronic equipment?

- <p>Yes, aluminum is widely used in electronic equipment due to its excellent electrical conductivity, lightweight nature, and high thermal conductivity. It is commonly used in heat sinks, cases, and connectors. However, it is not as conductive as copper, so it is often used in applications where its other properties are more critical. Additionally, aluminum's corrosion resistance makes it a durable choice for various electronic components.</p>

- Q: Explain how aluminum production and use contribute to global warming.

- <p>Aluminum production contributes to global warming through the emission of greenhouse gases, primarily carbon dioxide. The process of smelting aluminum from bauxite ore is energy-intensive, often relying on fossil fuels, which release CO2. Additionally, aluminum production generates perfluorocarbons (PFCs), potent greenhouse gases. The use of aluminum in various industries and products also has an indirect impact, as it drives demand for energy and resources. Furthermore, aluminum's longevity in landfills means it doesn't decompose, contributing to waste issues and indirectly affecting global warming through methane emissions from landfills.</p>

- Q: This question asks for methods to prevent aluminum from seeping into food when cooking with aluminum cookware.

- <p>To prevent aluminum from leaching into food when using aluminum cookware, follow these guidelines: Avoid using aluminum cookware for acidic foods or beverages, as acids can cause aluminum to leach. Do not cook with high heat, as this can increase the risk of leaching. Use a protective coating, such as a non-stick coating or a thin layer of oil, to create a barrier between the food and the aluminum. Regularly replace or repair any damaged cookware to prevent exposure to bare aluminum. Finally, consider using alternative cookware materials, such as stainless steel or cast iron, for long-term cooking and storage.</p>

- Q: Can aluminum recycling be done in a closed loop system where the material can be reused indefinitely without loss of quality?

- <p>Yes, aluminum can be recycled in a closed loop system. Aluminum is one of the most recycled materials due to its ability to be recycled indefinitely without losing quality. When aluminum is recycled, it retains its properties, making it suitable for reuse in new products. The closed-loop recycling process involves collecting used aluminum products, melting them down, and then using the recycled material to manufacture new aluminum products. This process can be repeated over and over again, making aluminum recycling highly efficient and environmentally friendly.</p>

- Q: Describe the process of electrolysis used in aluminum production.

- <p>The process of electrolysis for aluminum production involves the Hall-H茅roult process, which is the primary method for extracting aluminum from its ore, bauxite. First, bauxite is refined to produce aluminum oxide (alumina). This alumina is then dissolved in a molten cryolite bath, which lowers the melting point and increases the electrical conductivity. Large amounts of electricity are passed through the bath, causing the alumina to decompose into aluminum metal and oxygen gas. The aluminum collects at the bottom of the cell and is periodically tapped off, while the oxygen is released into the atmosphere. This energy-intensive process is crucial for the aluminum industry, as it allows for the production of large quantities of aluminum, a key material in various industries.</p>

- Q: This question asks for an explanation of the environmental effects caused by the process of smelting aluminum.

- <p>The environmental impact of smelting aluminum is significant. It is an energy-intensive process that contributes to greenhouse gas emissions, primarily due to the high electricity consumption required for the Hall-H茅roult process. This process also generates perfluorocarbons (PFCs), which are potent greenhouse gases. Additionally, the production of aluminum releases particulate matter and sulfur dioxide, contributing to air pollution. The extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Moreover, the waste products, such as red mud, can cause water pollution if not properly managed. Overall, the smelting of aluminum has considerable environmental implications, necessitating the development of more sustainable practices in the industry.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of components for aerospace applications?

- <p>Yes, aluminum is widely used in the aerospace industry for making various components due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is commonly used in aircraft structures, wings, fuselage, and engines. Aluminum alloys are preferred for their excellent fatigue resistance and ability to withstand high temperatures and stresses encountered in flight.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: Are aluminum alloys suitable for use in the aerospace industry?

- <p>Yes, aluminum alloys are extensively used in aerospace applications due to their high strength-to-weight ratio, corrosion resistance, and good fatigue characteristics. They are particularly favored for constructing airframes, wings, and other structural components where weight savings are critical. The alloys are also used in manufacturing engine parts and heat exchangers due to their thermal conductivity and ability to withstand high temperatures. However, the specific alloy selection depends on the particular requirements of the application, such as temperature resistance, strength, and environmental conditions.</p>

Send your message to us

Mill Finished PVDF Coated Aluminum Composite Panels - EN AW-3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords