Milk Powder Can Making Machinary for Cans Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

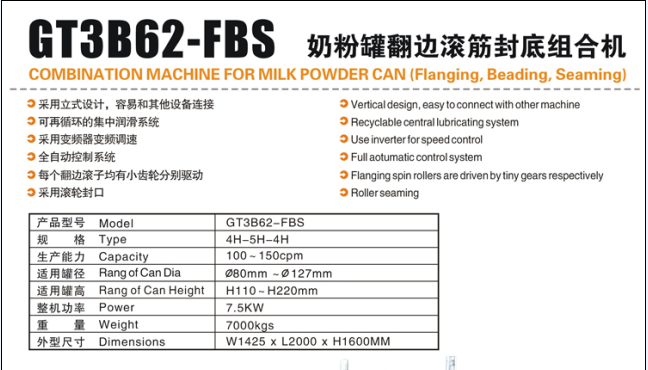

GT3B62-FBS Combination Machine for Milk Powder Can (Flanging, Beading, Seaming)

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

3. Images

4. Specification

1).NC table

Max. speed of arm and clamp: 36m/min

Feed precision: ±0.1mm

Working voltage: ~380V 50HZ

Rated power: 2KW

Outline size (L×W×H)(NC unit): 1740×2340×1045

Weight (NC unit): 1200kg

(2).35T press

Nominal pressure:350KN

Slide block travel distance:70mm

Number of times of travel:120Times/minute

Power:4KW

Outline size (L×W×H)(mm):1660*1340*2360

Weight:5000Kg

For more information:

5.FAQ

A: Do you have some other machinary, such as end making line?

Yes, we do have it.

B. What is the delivery?

It is around 45days, if you need more information, pls contact with us.

C: How about the package?

We use the seaworthy package, which is very safe.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

Send your message to us

Milk Powder Can Making Machinary for Cans Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords