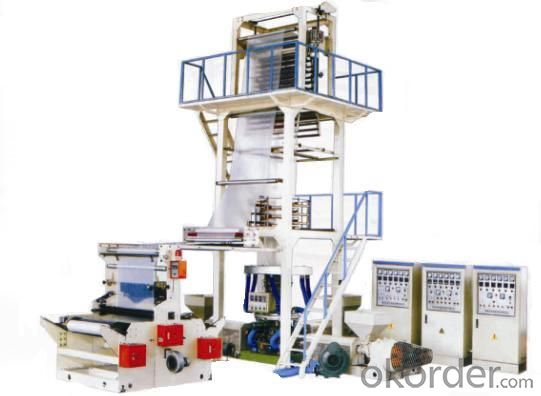

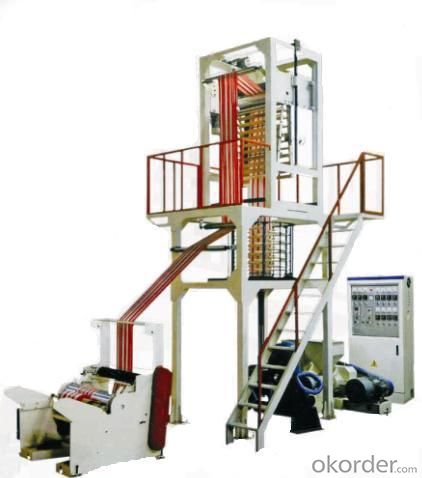

High Quality Mini Film Blowing Machine CM-M50

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information High Quality Mini Film Blowing Machine CM-M50

Its extruder, cylinder and screw rods are made of quality alloy steel that have been nitrizied and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polythene(LDPE), high density polythene(HDPE)and linear low density polythene(LLDPE).It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

Technical Data High Quality Mini Film Blowing Machine CM-M50

Model: CM-M50

Screw Diameter: Φ50 mm

Max.folding width of film: 100-600 mm

Single-side thickness of film(mm): 0.01-0.01 mm

Max. output: 50kg/h

Screw ratio L/D : 26:1

Main motor power (kw): 7.5-11 kw

Haul-off motor Power (kw): 1.1 kw

Heating power(kw) :11kw

Overall diameter(L×W×H)(mm) :3800×1900×3000 mm

Weight(T) : 1.5T

MiinOrder: 1set

Package: Package wooden carton

Packing of High Quality Mini Film Blowing Machine CM-M50

Packed with wooden carton of customized size and then placed on the pallet.

Storage Of High Quality Mini Film Blowing Machine CM-M50

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Remarks of High Quality Mini Film Blowing Machine CM-M50

Due to machine development, above information may be changed at any time without prior notice. The actual specifications are according to the agreement between buyer and seller.

Service of High Quality Mini Film Blowing Machine CM-M50

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 11% - 30% |

| No.of Employees in Trade Department | 5-7 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | capper, adhesive sheet machine, conveting machine, rewinder machine, slitting machine, machine for protective film |

| Product Price Range | High; Average |

Send your message to us

High Quality Mini Film Blowing Machine CM-M50

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 days/1 set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords