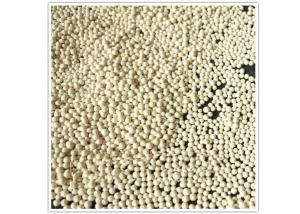

Micro Silica Fume 97 Rate Grey and White

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 3600 Tons per Mo m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Grey and white micro silica fume 97 rate

2.Stable quality

3.high tempreture to 1600 degree

4.can denisified to 650 k

Technical Data:

Index items | Standard Value |

SiO2(Silicon Dioxide) | Min. 97.0% |

C(Carbon) | Max. 0.7% |

Fe2O3 (Iron Oxide) | Max. 0.1% |

Al2O3(Aluminium Oxide) | Max. 0.3% |

CaO(Calcium Dioxide) | Max. 0.3% |

MgO(Magnesium Dioxide) | Max. 0.2% |

K2O(Potassium Dioxide) | Max. 0.3% |

Na2O(Sodium Dioxide) | Max. 0.2% |

P2O5(Phosphorus Pentoxide) | Max. 0.1% |

SO3(Sulphur Trioxide) | Max. 0.2 |

Cl (Chloride) | Max. 0.1% |

Moisture Content(H2O ) | Max. 0.5% |

Loss on Ignition(L.O.I) | Max. 0.5% |

Percent Retained On 45μm (325 sieve) | Max. 0.5% |

Bulk Density | 200-700kg/m3 |

Grey and white micro silica fume for refractory

Microsilica CAS #: 69012-64-2

Microsilica Packing: 900kg/jumbo bags or 20kg or 25kg small plastic woven bags.

- Q: I accidentally put my foot inside a wet cement container. Then, I fell asleep.....and when I woke up.....My foot is stuck to the container. I am not sure what to do? Should I drill the cement with a screwdriver to dig through or what?

- Call the nhs helpline or if you can go to a+e

- Q: in case of setting and hardening of cement, the first thing is stiffening

- its the initial stage of the cement setting up after it has been hydrated.

- Q: cement

- There are many types of cement. One is portland cement which is commonly used in construction. Please refer to this helpful links: OKorder

- Q: what are some pro and cons

- Cement counter tops are more expensive than Granite, per square foot. Very labor intensive to build. You then need a good sealer and need to be careful about stains.

- Q: I was watching amastad (sp) and pirates of carribean. They mentioned tying cement blocks to feet and throwing them over board. What happens to the human body? Do they drown first or are they crushed? I love learning new things. Plus I'm bored. So this thought came to mind. Anyone know what possibly happened to people way back when?

- It is really simple. If the water is deeper than the height of the person, they drown. If not, then they starve or get eaten by something. They don't get crushed because the cement will hit the bottom first as it is more dense than a person and will sink more quickly. The idea, and practice, of weighting live people, or dead bodies, with concrete or other weights, like chains, has been around for hundreds of years.

- Q: one that holds the best but not messy to work with

- You need to use Black Jack. It is messy, but that's what you need to seal the roof. Be careful when you work with it, and clean up immediately. Hope this helps.

- Q: My father has been using a really loud and strong nail gun to mount stuff in our new place that has cement walls. I did some research and found that you should drill a hole and do a bunch of other stuff as safety precautions. The website i found said that if there was an earthquake, the walls would crumble if you used a nail straight into cement. Is this true?I live in an area where we dont even have earthquakes often at all, which is Southern Ontario, Canada, but im still a little concerned because we had one last summer. Also, We live on the 10th floor, so if an earthquake does happen, it would shake a lot more up here. He also has been mounting stuff on the cement ceiling as well.Should I be concerned?

- No. Always drill into cement or concrete. Drilling makes a cleaner hole without cracks. When you crack cement, water and get in and when it freezes and melts it expands and contracts, further cracking the cement and allowing more water in. Salts in the water and also dissolve chalk in the cement and water can rust the re-bar if it gets to them. If you think about it, a drill uses a screw to pull material out of the wall. A nail merely pushes it out of the way. Since cement isn't that flexible, it tends to crack when expanding or deforming. A drill hole also makes a more secure anchoring point, since you don't have cracks around it and the spiral hole gives more grip on bolts you wish to put in it. There are lots of how to videos on this, but use a concrete bit and use liberal amounts of water on the bit. This both cool the bit and helps dampen the vibration caused by the drilling.

- Q: i'm finding it quite confusing =/ thank you.

- Cement is a powder-like substance;consists of aluminium, silicates etc. manufactured in a klin. Mortar is mixture of cement and sand. It is used to join bricks in a wall. Concrete is a mixture of cement, sand and aggregate(small stones) used to construct beam and columns.

- Q: The wind knocked over part of our wood fence. Two of the wood posts that were cemented into the dirt were uprooted. I figure the best way to fix the fence would be to use new posts (or bust off the old cement) and bury them in the ground with fresh cement. I'm feeling lazy and wonder if I do as good of a job just burying the old posts with the old cement back into the ground. Will it hold? Maybe this is a no-brainer for some folks - useful comments appreciated.

- First off if the wind blew the fence down then maybe you should go alittle deeper with the post. As to your next question, even though your feeling lazy it is best to knock out the old stuff (concrete) and pour new concrete post mix. If not then it is highly likely that you will be doing it again. Its pretty easy but time consuming. Good luck

- Q: I just poured cement anchors for a swingset. Eventually, I will cover the entire area with a tarp and then 3-4 inches of pea gravel. I'm wondering how long I should wait, to do this. Should I wait a week or so for the cement to cure more, before I cover it up? Or can I lay down the tarp immediately?

- You can cover it when ever you want. The cement is not drying, it is curing. The water does not evaporate from it, but there is a chemical reaction between the water, portland cement, and other components that make it harden to full strength. So have at it, just don't expect it to be at full strength till it finishes curing.

1. Manufacturer Overview

| Location | Luoyang, Henan, China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Oceania; Mid East; Eastern Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Micro Silica Fume 97 Rate Grey and White

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 3600 Tons per Mo m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords