Fiberglass Reinforced Masking Tape with Temperature Resistance 80 - SGS & ISO9001 Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

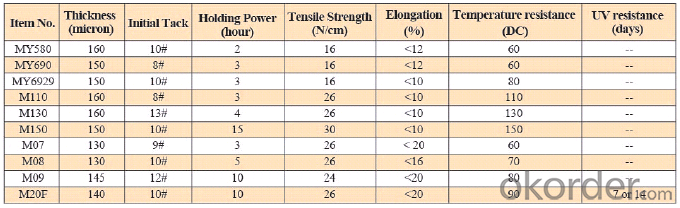

Typical Physical Reports of Masking Tape

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1800mm; width according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Are there any safety precautions to consider when using packaging tape?

- There are various safety measures to take into account when utilizing packaging tape. To begin with, it is vital to work in a well-ventilated area to avoid inhaling excessive adhesive fumes, which can be harmful. Furthermore, it is crucial to handle the tape dispenser cautiously to prevent any injuries. Ensure that your hand placement is correct and avoid placing your fingers too close to the cutting blade to avoid unintended cuts. Moreover, it is advisable to wear appropriate protective gear, such as gloves, when using packaging tape to shield your hands from potential adhesive residue or cuts. Finally, it is essential to store the tape in a safe and secure location, out of reach of children or pets, to prevent accidental ingestion or misuse. By adhering to these safety measures, you can guarantee a secure and effective utilization of packaging tape.

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. It provides a secure and temporary hold without causing damage to the frame's surface. However, it is important to remove the tape carefully to avoid peeling off any paint or finish.

- Q: Can packaging tape be used for sealing packages with electronic components?

- Indeed, packaging tape possesses the capability to seal packages containing electronic components effectively. Its purpose is to furnish packages with a sturdy and long-lasting seal, safeguarding the contents from external factors like moisture, dust, and physical harm. When sealing packages that house electronic components, it becomes crucial to verify the tape's strength in order to maintain package integrity and offer sufficient protection. Moreover, it is advisable to employ anti-static packaging tape exclusively created for electronic components, as this type aids in the dissipation of static electricity and serves as a preventive measure against potential harm to delicate electronics.

- Q: Are there any eco-friendly options for packaging tape?

- In today's market, there are various eco-friendly options for packaging tape. Typically, traditional packaging tapes are made from plastic materials like polypropylene or PVC, which are harmful to the environment and not biodegradable. However, there have been developments in creating eco-friendly alternatives to tackle this issue. Some of these options include: 1. Packaging tape made from paper: These tapes are crafted from renewable resources like paper and natural adhesives. They are both biodegradable and compostable, making them a sustainable choice for packaging requirements. 2. Gummed paper tape, also known as water-activated tape: This type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and provides tamper-proof sealing. Additionally, water-activated tape is biodegradable and can be recycled along with the packaging it is used on. 3. Biodegradable and compostable tape: These tapes are manufactured using plant-based materials such as cellulose or polylactic acid (PLA). They are designed to naturally break down over time, minimizing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: Although traditional plastic tapes are not environmentally friendly, there are recycled plastic tape options available in the market. These tapes are produced using recycled plastic materials, reducing the demand for new plastic and promoting a circular economy. When searching for eco-friendly packaging tape, it is crucial to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By opting for these alternatives, individuals and businesses can minimize their environmental impact and contribute to a more sustainable future.

- Q: How does packaging tape affect the weight of a package?

- The weight of a package is not directly influenced by packaging tape. Instead, it is determined by the contents within, including the item being shipped, any extra packaging materials, and the actual weight of the packaging. Packaging tape is utilized to secure the package's contents and guarantee their protection during transportation. Although the tape may have a slight weight, it is insignificant compared to the total weight of the package. As a result, the weight of a package is not significantly affected by the packaging tape.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various types of surfaces, including those that may be uneven or irregular. The strong adhesive properties of packaging tape ensure that it securely seals the package, even on surfaces that may not be completely flat or smooth. Additionally, packaging tape is flexible and can conform to the shape of the package, allowing for effective sealing on irregular surfaces. However, it is important to ensure that the tape is applied evenly and pressed firmly onto the surface to maximize its sealing capabilities.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, here are a few tips: 1. Use a dispenser: Invest in a tape dispenser specifically designed for packaging tape. The built-in cutting blade and roller mechanism will help keep the tape controlled and prevent tangling. 2. Start with a clean surface: Before applying the tape, ensure the surface is clean and free from dust, debris, or any other potential obstacles that may cause the tape to stick and tangle. 3. Avoid excessive handling: Minimize handling of the tape as much as possible. Each time you touch the tape, there is a higher chance of it twisting or tangling. Try to handle the tape only when necessary. 4. Cut the tape cleanly: Use a sharp cutter or a dispenser with a cutting blade to make clean and straight cuts. Jagged or uneven cuts can cause the tape to twist or tangle as it is being unrolled or applied. 5. Store it properly: When not in use, store the tape in a cool and dry place, away from direct sunlight or extreme temperatures. Keeping the tape in its original packaging or a designated container can also prevent tangling. 6. Unroll carefully: When unrolling the tape, hold the roll firmly and apply a slight tension to keep it straight. Avoid jerky movements or pulling the tape too forcefully, as this can cause it to twist or tangle. By following these tips, you can minimize the chances of packaging tape getting tangled, making your packaging process smoother and more efficient.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. Packaging tapes are designed to provide strong adhesion and durability, making them suitable for securing packages containing heavy-duty construction materials. However, it is essential to choose a packaging tape specifically designed for heavy-duty applications, such as reinforced or extra-strong tape, to ensure proper sealing and secure transportation. Additionally, it is advisable to reinforce the packaging with additional tape or protective wrapping, depending on the weight and fragility of the construction materials, to ensure safe and secure delivery.

- Q: Can packaging tape be used for sealing moving boxes?

- Yes, packaging tape is commonly used for sealing moving boxes. It provides a strong and secure seal, ensuring that the boxes remain closed and the contents are protected during transportation.

- Q: Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

Send your message to us

Fiberglass Reinforced Masking Tape with Temperature Resistance 80 - SGS & ISO9001 Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords