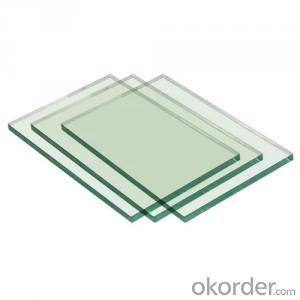

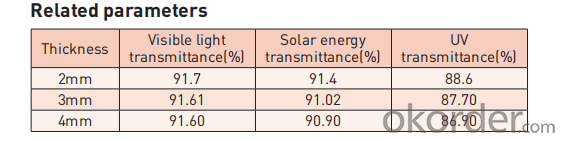

Manufacturer price ultra clear float glass sheet 4mm 5mm 6mm 8mm 10mm 12mm float glass panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 10000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Manufacturer price ultra clear float glass sheet 4mm 5mm 6mm 8mm 10mm 12mm float glass panel

Ultra clear glass is traditionally used at office buildings, Hospitals, Hotels, Houses and those buildings where large amount of heating or cooling is required. Those places where humidity and temperature needs to be controlled, Insulated glass is best suited for them.

Product Description

The most exciting buildings built today are the energy efficient, environment friendly and thoroughly green. Insulated Glass Unit (commonly referred to as IGU or IG unit) with Low-E coating has already become the first choice of modern architectures. It is no longer just to shield from the storm, but more importantly to integrate multifunction of thermal insulation, energy saving, artistry, quietness and safety. It provides a comfortable living space in which people can enjoy the four seasons, energy efficiency, environment-friendliness and brightness. The energy-saving characteristic of Low-E IGU are majorly manifested in its heat insulation and heat preservation performances. The main measuring indexes are Shading Coefficient (SC) or Solar Heat Gain Coefficient (SHGC), and the thermal conductivity coefficient (U Value).

Company Profile

>1. We are one of the biggest glass factory in China with over 25 year glass production experience, our factory occupies 50000 square meters, owing 5 production lines. Tempered glass daily productivity is 13000m2; laminated glass daily productivity is 8000m2, insulated glass daily productivity is 5000m2 etc.

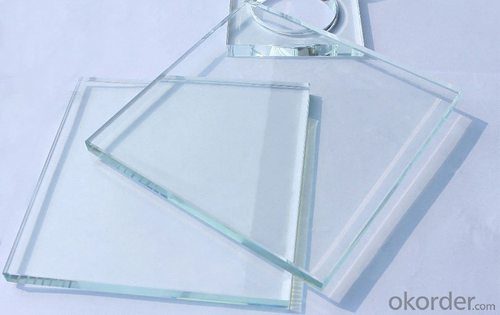

>2. Process by using grade A building glass materials, without any bubble, scratch, spot etc defects.

>3. Each step of our processing meet ISO, CE, SGS etc standard.

>4. Provide 10 years warranty, any quality problem can refund or replace glass.

>5. 100% inspection after production to make sure each sheet of glass are all in good condition.

>6. Use high quality newest seaworthy wooden crates to pack.

>7. Powerful transportation system and fast shipping time, we have long-term cooperation relationship with MAS, NYK, COSCO etc well-known shipping companies.

>8. Professional sales and technical team, provide 24-hour service, meet any specific requirements for glass.

Packing & Delivery

Step 1.Protective tape protects frames from scratches;

Step 2.Keep Glass sheet fixed on wood pallets;

Step 3.Tie up windows on the wood pallets with plastic belts

Step 4.PE films keep windows away from sea water;

Step 5.Fill in the space between each two wood pallets by air bags;

Step 6.Tie up wood pallets in container with plastic belts.Our packages will ensure the windows arrive at project jobsite in good conditions,pls contact us for details of packages,we will show you pictures.

FAQ

Q: What is the MOQ?

A: Generally, there is no MOQ for processed glass, but if you want to received best price, the more quantity,

the better price.

Q: Could I have a small sample to verify the quality?

A : Sure, we welcome sample to be tested and checked quality.

Q: Can I visit your factory?

A: Yes, we welcome all of customers visit our factory when you have real requirements, we will take

you to each of our production lines, and discussing orders in our office.

Q: Do you offer guarantee for the products?

A: Yes, generally, we offer 5 years warranty for processing glass based on your

normally uses, we advise you uses in a right way can keep your products service life in a long time (more than 5 years).

Q: How do you control the quality of your products?

A:We have standard management on factory based on ISO system, and train our staffs regularly, our production department they will choose high quality materials for glass strictly, for finished excellent products. And we have QC for each process, once find little problem, we will replace the glass, to make sure every piece glass go to warehouse is in good condition.

- Q: What are the national standards for broken aluminum doors and windows?

- The thermal conductivity coefficient of the aluminum windows and doors of the broken bridge is 3W / ㎡ · K, which is lower than that of the ordinary, and the heat transfer coefficient is 3W / Doors and windows heat loss by half, reduce the heating costs of about 30%, the sound insulation of 29 dB or more, watertight, air tightness is good, all up to the national A1 class window standard. Priority selection of high quality insulating glass, the original film is float glass, Standard is 5mm. Between the two pieces of glass between the aluminum and the thickness of the 12mm-15mm between. According to the doors and windows profiles specifications. Door and window hollow glass area is greater than 1.5 square meters to be steel processing. In the professional professional glass processing enterprises Production, Tianjin, more reliable manufacturers have 100 Thai and so on.

- Q: Who knows the windows of the house and how can you use the same as the stove plate?

- Pure natural, marble, with seams, the deeper the color, the greater the radiation, and easy to break Man-made, no seams, little radiation. Under normal circumstances, the threshold stone, windowsill marble, with natural or artificial marble

- Q: Broken bridge aluminum doors and windows are generally how much?

- Pinggai door is not easy to exceed the maximum width of 900MM, the maximum height is not easy to exceed 2400MM, sliding door is not easy to exceed the maximum width of 1000MM, the maximum high is not easy over 2400MM. Flat window is not easy to exceed the maximum width of 650MM, the maximum high is not easy to exceed 1500MM, the maximum width of the sliding window is not easy to exceed 900MM, the maximum high is not easy to exceed 1800MM

- Q: What is the material of the window stone

- Artificial stone or natural marble, artificial stone cheap, natural marble is also cheap, man-made mostly monochrome, natural marble texture more natural

- Q: What is the height of the building windowsill?

- Open to the public walkway of the sash, the bottom of the ground from the floor of the height should not be less than 2m. When less than 2m should not interfere with traffic, and to avoid sight interference.

- Q: Building drawings, C2415, is the size of the window or window hole size, how much difference

- That C shows the window, 2415 said the window is 2.4 meters long and 1.5 meters high. The hole is in the windows on the basis of each side put two to three centimeters.

- Q: Why the windowsill is not brick but concrete pouring

- Anti-cracking requirements, many places have such a provision, especially the first floor, the purpose is to control the uneven settlement caused by the window hole cracks.

- Q: The windowsill marble countertops are thicker

- The thickness of the different. Artificial stone has 1 cm 4 and 1 cm 7. Natural stone has 1 centimeter 2 and 1 centimeter 8.

- Q: What kind of material is the best of the countertops?

- Natural stone Natural stone, including a variety of patterns of granite, marble, more commonly used are two kinds of black and white flowers. Advantages: the density of natural stone is relatively large, hard texture, scratch performance is very prominent, good wear resistance, and the texture is very beautiful, the cost is relatively low, the most commonly used price of only a few hundred dollars or so, Affordable a countertop material. High-grade natural stone countertops also have a thousand dollars. Disadvantages: 1. Natural stone with pores, easy to accumulate grease; 2. Natural stone is short, two stitching can not be seamless, easy to breed bacteria; 3. Natural stone density, the need for strong cabinet support; , But the lack of flexibility, in case of a blow will be cracks, it is difficult to repair, some invisible natural cracks, the case of rapid changes in temperature will be broken; natural marble brittle, can not produce more than 1 meter format table. special reminder Natural stone part of the material may have radioactive and scattered gas, do not meet the environmental requirements, if not a special process, may cause harm to the human body, so the best choice for radiation testing.

- Q: What the best window

- Recommended the purchase of Philharmonic doors and windows, Jinyu Group is the second subsidiary.

Send your message to us

Manufacturer price ultra clear float glass sheet 4mm 5mm 6mm 8mm 10mm 12mm float glass panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 10000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches