Manhole Cover Ductile Iron EN124 from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Cast Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

Manhole covers are often made out of cast iron, concrete or a combination of the two. This makes them inexpensive, strong, and heavy, usually weighing more than 50 kilograms (110 lb). The weight helps to keep them in place when traffic passes over them, and makes it difficult for unauthorised people not having suitable tools to remove them.

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

2.Main Features of the Ductile Iron Manhole Cover:

·High endurance

·High Strength

·Pressure Resistence

·Anti-corrosion

·Anti-theft

·Good visual effect

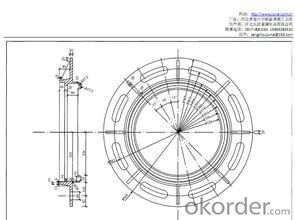

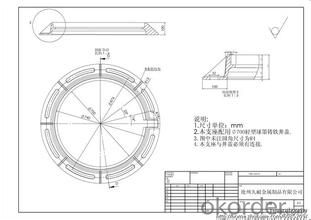

3.Manhole Cover Images:

4.Manhole Cover Specifications:

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I’ve measured my clear opening size but none of your covers match it, can you offer anything?

A. It’s likely that your cover is quite old and in imperial measurements which are no longer manufactured. However, we can offer bespoke solutions with manhole covers made to the specification you require.

Q. The project I’m working on requires a manhole cover with a quality finish, what’s available?

A. Naturally, galvanised steel of black polypropylene aren’t always ideal, and so we offer brass or stainless steel edging, as well as complete stainless steel covers.

Q. Odours are coming through where I have installed my manhole cover, why?

A. Your cover must be sealed and locked, or neoprene sealed, so you would require a T-Range Cover, or if you require a solid top, a selection of the PC range (e.g. PC2BG3, PC6CG3, not PC2BG) are suitable.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from scopeShanghai Zhejiang forest auto parts experts pointed out that the forging process can eliminate cast loose, metal welding holes, so an important part of high load working conditions, severe machinery, in addition to relatively simple shapes can be rolled plates, profiles or welded parts, the forging process. Because of its low cost and good economy, casting parts processing is widely applied and belongs to the basic process of modern machine building industry.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Manhole Cover Ductile Iron EN124 from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords