Manas Geotextile for Reinforced Filtration Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

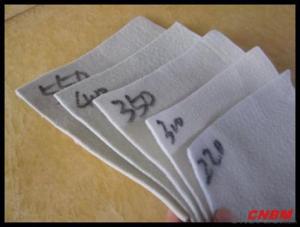

Specifications of Geotextile for Reinforced Filtring Road:

-Reinforced filtering road geotextile

-quality:good quality

-strength:high strength

-tencity:well

-packagel:woven bags

TDS of Geotextile for Reinforced Filtring Road:

NO | Reinforced filtring road geotextile | |

1 | Materaial | Polyester (PET) and polypropylyne(PP) |

2 | Delievery | 7 days after payment |

3 | Package | Woven bags usually, as your requirement |

4 | Color | White,black,gray |

5 | Install | Convinient and safely |

6 | Sale Status | Popular and well selling |

7 | Payment | TT/LC/Western Union,Paypal |

8 | Price | 01-4.0 USD |

9 | After sale service | Professional suggestions and send sample if you want |

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing reinforcement and filtration. They act as a barrier to prevent the loss of soil particles while allowing water to pass through, thereby enhancing the stability and strength of geotubes. Additionally, geotextiles help distribute loads evenly, reducing the risk of erosion and increasing the overall performance and longevity of geotubes.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- Geotextiles generally do not design applications in tunnel waterproofing. Because he can not meet the requirements of tunnel waterproofing

- Q: How are geotextiles used in road construction?

- Geotextiles are used in road construction to enhance the structural integrity and lifespan of the road. They are placed between the subgrade and the base course to prevent soil erosion, improve drainage, and provide separation and filtration. Geotextiles also help to distribute loads and reduce cracking and rutting in the road surface.

- Q: Where is the non-woven geotextile in the tunnel?

- The nonwoven geotextile is used to isolate the dome between the concrete and the waterproof layer in the tunnel.

- Q: Designers give blind ditch length of 540m, geotextile for 2835m2 more

- Lovel new materials geotextile raw materials: geotextile raw materials used not only to consider its use in the environment required physical and chemical properties, but also pay attention to product costs.

- Q: Roof geotextile isolation layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: Can geotextiles be used in retaining wall drainage systems?

- Yes, geotextiles can be used in retaining wall drainage systems. Geotextiles are commonly used as a filter fabric to prevent the migration of fine particles into the drainage system, while allowing water to flow through. By placing geotextiles behind the retaining wall, they help to enhance the drainage efficiency and overall stability of the system.

- Q: How do geotextiles aid in the reduction of soil compaction?

- Geotextiles aid in the reduction of soil compaction by providing a barrier between the soil and external loads, distributing the load more evenly and reducing the pressure on the soil. This allows the soil to retain its natural structure and porosity, thereby minimizing compaction and preserving its ability to absorb and drain water effectively.

- Q: What are the experiments required for earthwork dam geotextiles

- The first thing to do is the "unit area quality" and "thickness", followed by "breaking strength", breaking elongation "," CBR broken strength ", and tear strength. Huazhi geotextile for your answer

Send your message to us

Manas Geotextile for Reinforced Filtration Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords