Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Made in China stainless steel chimney pipe

Our Services

We assure you:

Small MOQ + Cheap Price + Good Quality + Fast Delivery

OUR STRENGTH

1.100% Manufacturer.

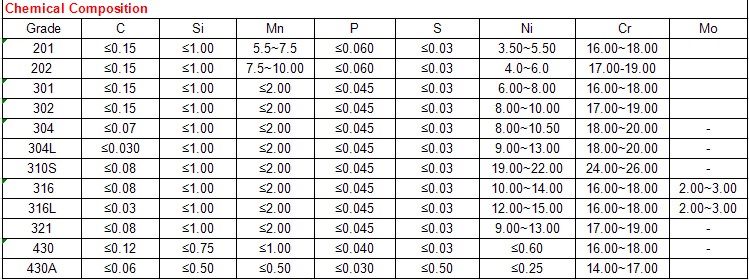

2. Specializing in processing 200 / 300 / 400 / 900 series stainless steel.

3. Well-trained and experienced staffs.

4. Able to answer all your enquiries in fluent English.

5. Russian enquiries can be well understand and replied

FAQ

1. Small quantity, short time delivery

If we have stocks, we can ship from a minimum of 1 kg sample in a few days. We also manufacture custom-order materials in amounts of 300 kg and up (Some materials are allowed 50 kg) in as few as 3 weeks.

2. High-precision thickness

We guarantee thickness tolerances that cannot be reproduced by competitors.

Example:

t <0.30mm tolerance ±1 - 3 μm guaranteed

0.30 mm≤t Tolerance ± 1% guaranteed

3. Ability to add multiple features

We are capable of adding a variety of features to metallic materials(resin coating, plating, bonding different kinds of metal, multigage skiving, etc.).

4. Unique technology and custom-made solutions

We provide customed solutions to your problems with our unique technologies and well versed knowledge of materials acquired through our experience of manufacturing 50,000 items.

5. Choose the appropriate base metals for your needs.

We carefully balance quality, delivery time and price,procure various base metals from all over the world.

We manufacture appropriate products to your needs.

6. To control metal structure(chemical formation)

We can manufacture ultrafine metal structures with a grain size of 1 μm. Using finer grain sizes provides benefits such as hardenability,balancing strength and ductility, and precision press processing.

7. Lower total cost

We taking your processing into account,offer you reduce a total cost by using our product.

8. Global network

Our plant located in Japan, Shanghai and Taiwan,we also support flexibly local procurement and production transfer.

- Q: How do you prevent leakage in stainless steel pipes?

- To prevent leakage in stainless steel pipes, there are several measures that can be taken: 1. Proper installation: Ensure that the stainless steel pipes are installed correctly by trained professionals who have expertise in working with stainless steel. This includes using appropriate fittings, connectors, and seals to ensure a tight and secure connection. 2. Regular inspections: Conduct routine inspections to identify any signs of leakage such as corrosion, cracks, or loose fittings. This allows for proactive maintenance and repairs before a major leak occurs. 3. Use high-quality materials: Choose stainless steel pipes that are made from high-grade materials and comply with industry standards. Low-quality materials or substandard manufacturing can lead to weak spots and increased risk of leakage. 4. Proper sealing: Use effective sealing methods such as gaskets, o-rings, or thread sealants to create a tight seal between pipe joints. This prevents any potential leakage points where fluids or gases can escape. 5. Pressure testing: Conduct pressure tests on the stainless steel pipes to ensure their integrity before they are put into operation. This helps identify any weaknesses or leaks that may have occurred during installation. 6. Regular maintenance: Implement a regular maintenance schedule to inspect and maintain stainless steel pipes. This includes checking for signs of corrosion, replacing worn-out seals or gaskets, and tightening fittings as necessary. 7. Avoid over-tightening: While it is important to ensure a secure connection, over-tightening fittings can lead to stress and damage to the pipe, which can result in leaks. Follow the manufacturer's guidelines for proper tightening torque. 8. Proper pipe support: Ensure that stainless steel pipes are adequately supported and secured to prevent stress or movement that can cause leaks. This includes using appropriate hangers, clamps, or brackets suitable for stainless steel pipes. By following these preventive measures, the likelihood of leakage in stainless steel pipes can be greatly reduced, ensuring the long-term integrity and reliability of the piping system.

- Q: What is the difference between seamless and LSAW stainless steel pipes?

- Different industries commonly use seamless and LSAW stainless steel pipes. The manufacturing process and resulting structural characteristics distinguish these two types of pipes. Seamless stainless steel pipes are produced without any seams or welds. Manufacturers achieve this by piercing a solid cylindrical billet and extruding it to create a hollow tube. This technique ensures a uniform cross-section, resulting in a smooth and consistent inner and outer surface. The absence of welds eliminates potential weak points, enhancing the overall strength and integrity of the pipe. Seamless pipes are known for their superior corrosion resistance and are often preferred in critical applications where leakage must be avoided. In contrast, LSAW stainless steel pipes are formed by bending and welding a steel plate or coil into a cylindrical shape. The welding process involves passing an electric arc through the steel plate and the welding filler material, creating a visible seam on the pipe's exterior. LSAW pipes are commonly used in applications requiring large diameters and thick walls, such as oil and gas transportation. They can be produced in longer lengths and with larger diameters compared to seamless pipes. Seamless stainless steel pipes are generally more expensive to manufacture than LSAW pipes due to their complex production process. However, their seamless construction offers superior performance and reliability, making them the preferred choice for critical applications. On the other hand, LSAW pipes provide a cost-effective solution for large-scale projects where the visible seam is not a concern. To summarize, the main differences between seamless and LSAW stainless steel pipes lie in their manufacturing process, structural characteristics, and cost. Seamless pipes are made without seams or welds, providing excellent corrosion resistance and strength. LSAW pipes, on the other hand, are created by bending and welding a steel plate, offering a cost-effective solution for large-scale projects. The choice between these two types of pipes depends on the specific requirements of the application and the desired balance between cost and performance.

- Q: What are the different types of stainless steel pipe tees?

- There are several different types of stainless steel pipe tees, each designed for specific applications and requirements. 1. Equal Tee: This type of tee has three outlets of the same size, forming a 90-degree angle. It is commonly used to branch off or combine flow in a pipeline with equal diameters. 2. Reducing Tee: As the name suggests, a reducing tee has one outlet smaller than the other two. It is used to connect pipes of different sizes, allowing for a smooth transition in the flow of fluids or gases. 3. Barred Tee: This tee has a bar welded across the branch opening, providing additional support and reinforcement. It is commonly used in high-pressure or high-temperature applications to prevent stress concentration and potential failure. 4. Lateral Tee: A lateral tee has one outlet at a 45-degree angle, allowing for a branch connection at a different direction. It is often used in situations where a pipeline needs to be diverted or connected at an angle. 5. Cross Tee: A cross tee has four outlets forming a cross-shaped configuration. It is used when there is a need to split or combine flow in multiple directions, commonly found in complex piping systems. 6. Unions and Socket Weld Tee: These types of tees have sockets or unions at the branch connection, allowing for easy disassembly and maintenance. They are often used in applications where regular inspection, cleaning, or replacement is required. 7. Threaded Tee: Threaded tees have threaded branch connections, which can be screwed onto the pipe without the need for welding. They are commonly used in low-pressure applications or when frequent disassembly is required. Each type of stainless steel pipe tee offers specific advantages and is selected based on the requirements of the particular piping system, such as flow rates, pressure, temperature, and compatibility with the fluids or gases being transported.

- Q: How do stainless steel pipes compare to PVC pipes?

- Stainless steel pipes and PVC pipes are utilized extensively in various industries and applications, but they possess distinct dissimilarities that render them suitable for different purposes. A crucial disparity lies in their material composition. Stainless steel pipes are crafted from an amalgamation of iron, chromium, and other elements, affording them exceptional strength and resistance to corrosion. Conversely, PVC pipes are constructed from a synthetic plastic polymer called polyvinyl chloride, which provides good chemical resistance but lacks the strength of stainless steel. Concerning strength and durability, stainless steel pipes hold the advantage. They can endure high pressure and exhibit remarkable heat resistance, rendering them ideal for tasks involving the conveyance of hot liquids or gases. PVC pipes, although less robust, are lightweight and flexible, making them easier to manipulate and install in specific applications. Another vital aspect to consider is cost. PVC pipes generally boast a more affordable price compared to stainless steel pipes, hence their popularity in residential plumbing and low-pressure applications. Stainless steel pipes, due to their higher expense, find more usage in industrial settings where superior strength and resistance to corrosion are imperative. In terms of lifespan, stainless steel pipes enjoy a lengthier expectancy compared to PVC pipes. Stainless steel demonstrates high resistance to corrosion, rust, and other chemical reactions, enabling it to maintain its structural integrity over a longer duration. PVC pipes, while durable, can deteriorate over time due to exposure to UV light, extreme temperatures, and certain chemicals. Concerns surrounding environmental impact have been raised regarding PVC pipes over the years due to the production and disposal processes, which involve the release of toxic chemicals. In contrast, stainless steel pipes are deemed more environmentally friendly as they can be recycled and possess a lengthier lifespan. In conclusion, stainless steel pipes and PVC pipes possess their own unique characteristics and benefits. Stainless steel pipes excel in strength, durability, and resistance to corrosion, making them suitable for high-pressure and high-temperature applications. PVC pipes, in contrast, are lightweight, cost-effective, and easy to install, making them a popular choice for low-pressure applications. Ultimately, the selection between these two materials hinges on the specific requirements and limitations of the project at hand.

- Q: Can stainless steel pipes be coated with epoxy?

- Stainless steel pipes have the ability to be coated with epoxy, which is frequently utilized in a variety of industries to safeguard and enhance the performance of these pipes. By creating a protective barrier against corrosion, chemical damage, and abrasion, the epoxy coating effectively extends the pipes' lifespan. Moreover, it aids in enhancing the pipes' flow efficiency by minimizing friction and preventing the accumulation of deposits or scaling. Additionally, the application of epoxy coatings to stainless steel pipes allows for aesthetic purposes such as customization and color-coding of different pipe systems. In summary, the utilization of epoxy coatings on stainless steel pipes offers numerous advantages in terms of safeguarding, durability, and functionality.

- Q: What are the standard sizes for stainless steel pipes?

- The standard sizes for stainless steel pipes can vary depending on the industry and application. However, there are some commonly used standard sizes that are widely available. In general, stainless steel pipes are produced in nominal sizes ranging from 1/8 inch to 72 inches in diameter. These sizes are typically classified using the Nominal Pipe Size (NPS) system, which refers to the approximate internal diameter of the pipe. The NPS sizes commonly used for stainless steel pipes range from NPS 1/8 to NPS 36. Additionally, stainless steel pipes are available in various schedules, which indicate the wall thickness of the pipe. The most commonly used schedules for stainless steel pipes are Schedule 5, Schedule 10, Schedule 40, and Schedule 80. It's important to note that these standard sizes may vary slightly depending on the country or region. Therefore, it is advisable to consult the relevant standards and regulations specific to your location or consult with a supplier to determine the exact standard sizes available for stainless steel pipes in your area.

- Q: What is the difference between 409 and 316 stainless steel pipes?

- The main difference between 409 and 316 stainless steel pipes lies in their chemical composition and properties. 409 stainless steel is a ferritic stainless steel known for its good corrosion resistance, high temperature resistance, and relatively low cost. It is commonly used in automotive exhaust systems and other applications where corrosion resistance is important. On the other hand, 316 stainless steel is an austenitic stainless steel with superior corrosion resistance compared to 409. It contains molybdenum, which enhances its resistance to corrosion by various chemicals, acids, and saltwater. 316 stainless steel pipes are often used in marine environments, food processing plants, and other applications where exceptional corrosion resistance is required. In summary, while both 409 and 316 stainless steel pipes offer corrosion resistance, 316 stainless steel provides higher resistance to corrosion in a wider range of environments, making it more suitable for demanding applications.

- Q: How much is one ton of stainless steel pipe?

- Basically, each shop is not the same, each place is not the same, you can ask more about the goods than three?

- Q: Can stainless steel pipes be used for petrochemical plants?

- Certainly, petrochemical plants can utilize stainless steel pipes. Due to its exceptional resistance to corrosion, stainless steel emerges as an optimal selection for such plants that deal with corrosive substances. These pipes possess the ability to endure extreme temperatures and pressures, rendering them appropriate for the demanding operational circumstances of petrochemical plants. Furthermore, stainless steel pipes exhibit outstanding mechanical qualities, guaranteeing their endurance and dependability within industrial settings. Moreover, the ease of cleaning and maintenance associated with stainless steel pipes minimizes the likelihood of contamination and enhances operational efficiency in petrochemical plants.

- Q: How do you cut stainless steel pipes?

- Cutting stainless steel pipes can be done using several methods. Here are a few common techniques: 1. Using a hacksaw: This is a manual method of cutting stainless steel pipes. Make sure to choose a blade specifically designed for cutting metal. Secure the pipe in a vise or clamp to prevent it from moving while cutting. Mark a straight line where you want to cut and slowly and steadily saw through the pipe using back and forth motions. Apply consistent pressure to avoid damaging the pipe. 2. Using a reciprocating saw: A reciprocating saw with a metal cutting blade can also be used to cut stainless steel pipes. Clamp the pipe securely and mark the cutting line. Start the saw and slowly guide it along the marked line, applying steady pressure. This method is quicker than using a hacksaw and requires less manual effort. 3. Using a pipe cutter: A pipe cutter is a specialized tool designed to cut pipes cleanly and accurately. It consists of a sharp cutting wheel that is rotated around the pipe, gradually tightening it until the pipe is cut. This method is efficient and provides a smooth, burr-free cut. However, it may not be suitable for thicker or larger diameter stainless steel pipes. 4. Using a plasma cutter or a grinder: For thicker or larger diameter stainless steel pipes, a plasma cutter or a grinder equipped with a cutting wheel can be used. These power tools are capable of cutting through stainless steel quickly and efficiently. However, they require more expertise and safety precautions, so it is recommended to seek professional assistance if you are not familiar with these tools. Remember to wear appropriate safety gear, such as gloves and eye protection, when cutting stainless steel pipes. Additionally, always double-check the accuracy of your measurements and take necessary precautions to avoid injury.

Send your message to us

Made in China Stainless Steel Chimney Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords